Ultra-High Performance Concrete (UHPC) offers significantly greater strength, durability, and density compared to High-Performance Concrete (HPC), making it ideal for advanced engineering applications where longevity and load-bearing capacity are critical. UHPC incorporates fine powders, fibers, and optimized particle packing to achieve compressive strengths exceeding 150 MPa, while HPC typically ranges between 50 and 100 MPa. The enhanced microstructure of UHPC results in superior resistance to abrasion, corrosion, and environmental degradation, outperforming HPC in extreme conditions.

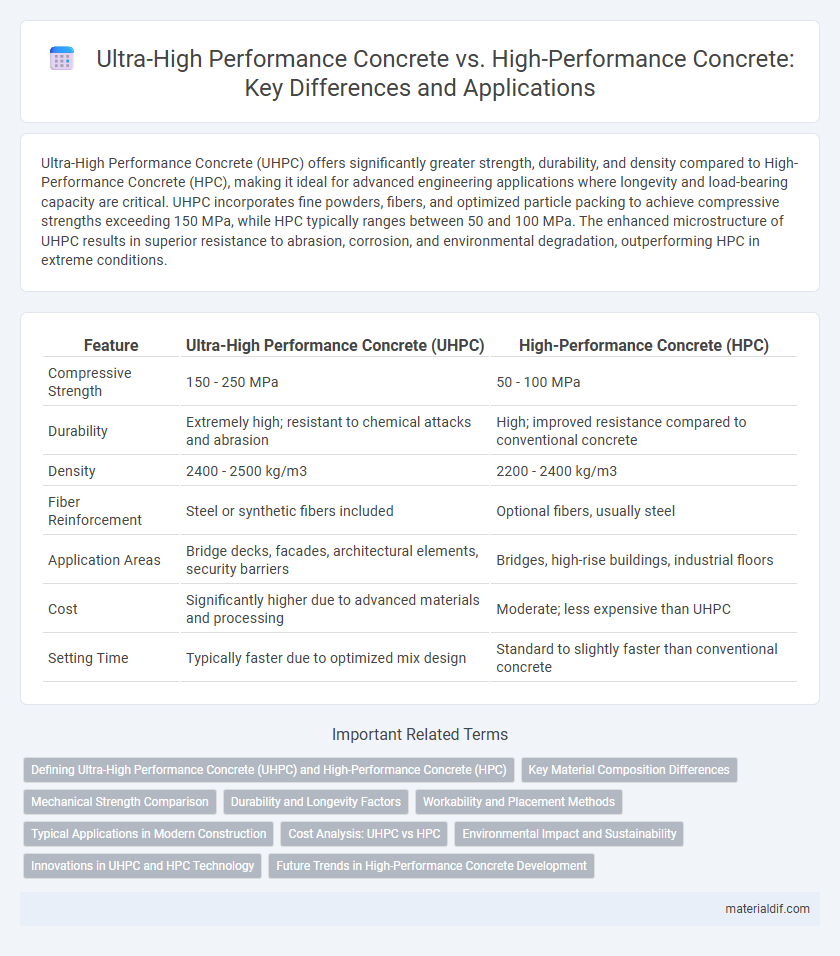

Table of Comparison

| Feature | Ultra-High Performance Concrete (UHPC) | High-Performance Concrete (HPC) |

|---|---|---|

| Compressive Strength | 150 - 250 MPa | 50 - 100 MPa |

| Durability | Extremely high; resistant to chemical attacks and abrasion | High; improved resistance compared to conventional concrete |

| Density | 2400 - 2500 kg/m3 | 2200 - 2400 kg/m3 |

| Fiber Reinforcement | Steel or synthetic fibers included | Optional fibers, usually steel |

| Application Areas | Bridge decks, facades, architectural elements, security barriers | Bridges, high-rise buildings, industrial floors |

| Cost | Significantly higher due to advanced materials and processing | Moderate; less expensive than UHPC |

| Setting Time | Typically faster due to optimized mix design | Standard to slightly faster than conventional concrete |

Defining Ultra-High Performance Concrete (UHPC) and High-Performance Concrete (HPC)

Ultra-High Performance Concrete (UHPC) is characterized by compressive strengths exceeding 150 MPa, enhanced durability, and superior mechanical properties due to its optimized mixture of fine powders, fibers, and chemical admixtures. High-Performance Concrete (HPC) typically achieves compressive strengths between 50 and 100 MPa, offering improved workability, durability, and strength compared to conventional concrete but with less advanced material composition than UHPC. The defining distinction lies in UHPC's exceptional microstructure densification and fiber reinforcement, enabling unparalleled resilience and longevity in demanding construction applications.

Key Material Composition Differences

Ultra-High Performance Concrete (UHPC) distinguishes itself from High-Performance Concrete (HPC) primarily through its advanced material composition, featuring a higher cement content often exceeding 800 kg/m3 and a greater proportion of fine silica sand, along with the inclusion of steel or synthetic fibers to enhance tensile strength and durability. HPC typically contains lower cement content around 400-600 kg/m3 and relies more on traditional aggregates with limited fiber reinforcement. The optimized particle packing in UHPC's mix design results in significantly reduced porosity and superior mechanical properties compared to HPC.

Mechanical Strength Comparison

Ultra-High Performance Concrete (UHPC) exhibits compressive strengths exceeding 150 MPa, significantly surpassing High-Performance Concrete (HPC), which typically ranges from 70 to 100 MPa. UHPC's enhanced mechanical strength results from its dense microstructure and advanced fiber reinforcement, providing superior tensile and flexural performance compared to HPC. This remarkable strength improvement enables UHPC to be used in demanding structural applications requiring exceptional durability and load-bearing capacity.

Durability and Longevity Factors

Ultra-High Performance Concrete (UHPC) exhibits superior durability compared to High-Performance Concrete (HPC) due to its dense microstructure and optimized fiber reinforcement, which significantly reduce permeability and improve resistance to chemical attacks and freeze-thaw cycles. UHPC's enhanced compressive strength, often exceeding 150 MPa, contributes to longer service life in aggressive environments where HPC typically ranges between 50-100 MPa. The advanced curing processes and minimal water-to-cement ratio in UHPC further enhance its longevity by mitigating shrinkage and cracking risks commonly associated with HPC.

Workability and Placement Methods

Ultra-High Performance Concrete (UHPC) exhibits superior workability due to its optimized particle packing and low water-to-cement ratio, enabling self-consolidation and reducing the need for mechanical vibration during placement. High-Performance Concrete (HPC) generally requires more conventional placement methods, including vibration, to ensure proper compaction and uniformity. UHPC's advanced rheology allows for precise molding and complex forms, making it ideal for intricate architectural elements and thin structural components.

Typical Applications in Modern Construction

Ultra-High Performance Concrete (UHPC) is predominantly used in bridge construction, facade panels, and security structures due to its exceptional durability and high compressive strength exceeding 150 MPa. High-Performance Concrete (HPC), with compressive strengths typically ranging from 50 to 100 MPa, is widely applied in high-rise buildings, parking structures, and infrastructure projects requiring enhanced durability and reduced permeability. Both materials contribute to modern construction by improving structural longevity and reducing maintenance costs, with UHPC reserved for specialized, load-critical applications.

Cost Analysis: UHPC vs HPC

Ultra-High Performance Concrete (UHPC) commands a significantly higher initial cost than High-Performance Concrete (HPC) due to its advanced materials like fine powders, steel fibers, and specialized admixtures, which elevate raw material expenses by 3 to 5 times compared to HPC. Although UHPC's superior durability, reduced maintenance needs, and extended lifespan offer long-term economic benefits, the upfront investment remains a critical factor influencing project budgets. Cost-benefit analysis must consider lifecycle savings from UHPC's enhanced mechanical properties and reduced structural mass against HPC's lower initial expenditure and broader availability.

Environmental Impact and Sustainability

Ultra-High Performance Concrete (UHPC) offers superior durability and reduced permeability compared to High-Performance Concrete (HPC), leading to longer service life and lower maintenance needs, which significantly decreases environmental impact over time. The dense microstructure of UHPC enables the use of less cement and supplementary cementitious materials such as fly ash and silica fume, reducing CO2 emissions associated with cement production. Lifecycle assessments reveal that despite higher initial energy inputs, UHPC's enhanced strength and durability contribute to improved sustainability by minimizing material consumption and waste in construction projects.

Innovations in UHPC and HPC Technology

Ultra-High Performance Concrete (UHPC) exhibits superior compressive strengths often exceeding 150 MPa, far surpassing High-Performance Concrete (HPC) with strengths typically ranging from 50 to 100 MPa, due to innovations in nanomaterial integration and optimized particle packing density. Advances in UHPC technology include the incorporation of steel fibers and reactive silica fume, which enhance durability, tensile strength, and resistance to environmental degradation compared to traditional HPC mixes. Emerging innovations in HPC focus on sustainable mix designs using supplementary cementitious materials like fly ash and slag, improving workability and reducing carbon footprint while maintaining high strength and durability characteristics.

Future Trends in High-Performance Concrete Development

Future trends in high-performance concrete development emphasize incorporating nano-materials and advanced fiber reinforcements to enhance durability and mechanical properties. Researchers are exploring eco-friendly cement alternatives and optimized mix designs to reduce carbon footprints while maintaining ultra-high strength levels. The integration of smart monitoring technologies aims to improve long-term structural health assessment and performance predictability in both ultra-high performance concrete and traditional high-performance concrete applications.

Ultra-High Performance Concrete vs High-Performance Concrete Infographic

materialdif.com

materialdif.com