Reinforced concrete contains steel bars or mesh embedded to resist tensile forces, enhancing its overall strength and durability. Prestressed concrete involves introducing internal stresses through tensioned steel tendons before loading, improving load capacity and reducing cracking. This prestressing technique allows for longer spans and thinner sections compared to traditional reinforced concrete.

Table of Comparison

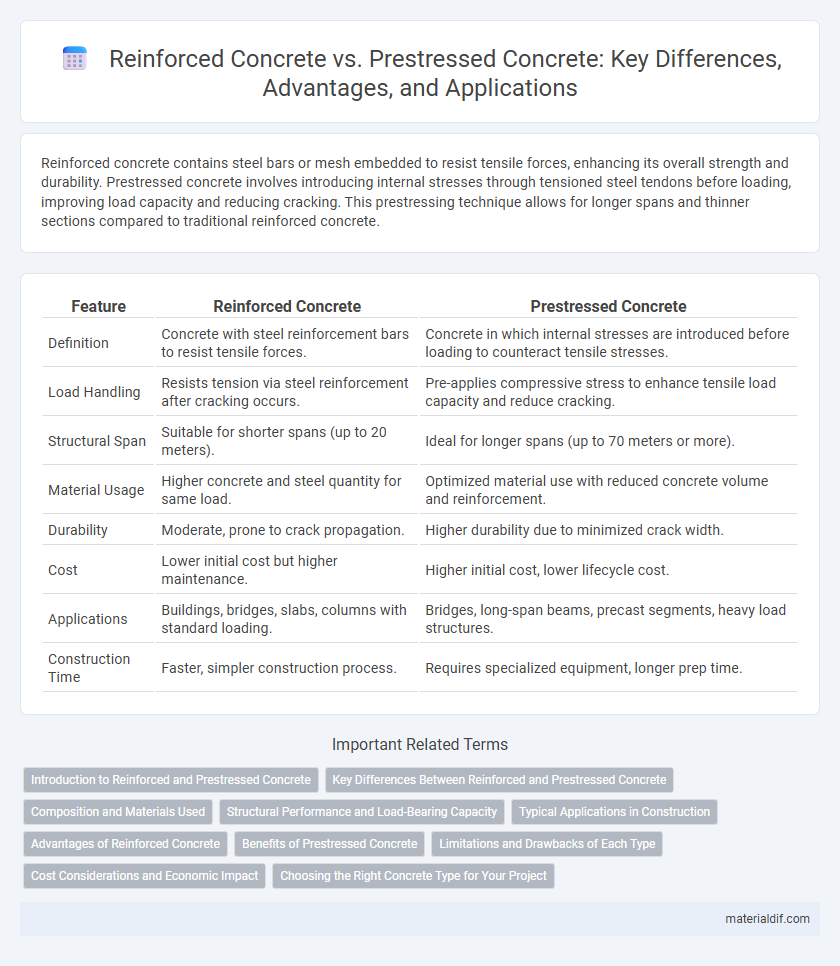

| Feature | Reinforced Concrete | Prestressed Concrete |

|---|---|---|

| Definition | Concrete with steel reinforcement bars to resist tensile forces. | Concrete in which internal stresses are introduced before loading to counteract tensile stresses. |

| Load Handling | Resists tension via steel reinforcement after cracking occurs. | Pre-applies compressive stress to enhance tensile load capacity and reduce cracking. |

| Structural Span | Suitable for shorter spans (up to 20 meters). | Ideal for longer spans (up to 70 meters or more). |

| Material Usage | Higher concrete and steel quantity for same load. | Optimized material use with reduced concrete volume and reinforcement. |

| Durability | Moderate, prone to crack propagation. | Higher durability due to minimized crack width. |

| Cost | Lower initial cost but higher maintenance. | Higher initial cost, lower lifecycle cost. |

| Applications | Buildings, bridges, slabs, columns with standard loading. | Bridges, long-span beams, precast segments, heavy load structures. |

| Construction Time | Faster, simpler construction process. | Requires specialized equipment, longer prep time. |

Introduction to Reinforced and Prestressed Concrete

Reinforced concrete incorporates steel reinforcement bars (rebars) to enhance tensile strength, making it suitable for structural elements subjected to tension and bending. Prestressed concrete involves preloading the steel tendons through tension before applying service loads, resulting in improved performance under compression and reduced cracking. Both methods optimize concrete's inherent properties but differ in tension management and structural efficiency for various construction applications.

Key Differences Between Reinforced and Prestressed Concrete

Reinforced concrete uses steel bars or mesh embedded within to resist tensile forces, while prestressed concrete applies intentional compressive stresses through tensioned steel tendons before loading. This pre-compression in prestressed concrete enhances structural capacity and reduces cracking, enabling longer spans and lighter sections compared to conventional reinforced concrete. Reinforced concrete is more suitable for general construction, whereas prestressed concrete is preferred in bridges, parking structures, and high-performance applications demanding greater durability and load resistance.

Composition and Materials Used

Reinforced concrete consists of conventional steel bars or mesh embedded within the concrete to resist tensile forces, utilizing common Portland cement, aggregates, and water as the matrix. Prestressed concrete incorporates high-strength steel tendons or cables, which are tensioned before or after concrete casting, allowing the material to handle higher stress and minimize cracking. Both types rely on a similar concrete mix design but differ significantly in the type and application of steel reinforcement for optimized structural performance.

Structural Performance and Load-Bearing Capacity

Reinforced concrete incorporates steel reinforcement bars to resist tensile stresses, enhancing ductility and overall structural reliability under dynamic loading conditions. Prestressed concrete uses tensioned steel tendons to counteract tensile forces preemptively, resulting in superior load-bearing capacity and reduced cracking compared to conventional reinforced concrete. The prestressing process significantly improves structural performance in long-span bridges and high-load applications by increasing flexural strength and serviceability.

Typical Applications in Construction

Reinforced concrete is commonly used in residential buildings, bridges, and foundations due to its ability to withstand tensile and compressive stresses with embedded steel rebar. Prestressed concrete is preferred for long-span structures such as bridges, parking garages, and high-rise buildings, offering enhanced load-bearing capacity and reduced structural deflection. Typical applications of prestressed concrete include beams, slabs, and girders where high strength and durability are critical.

Advantages of Reinforced Concrete

Reinforced concrete offers superior ductility and improved crack control compared to prestressed concrete, making it ideal for structures subjected to dynamic loads or seismic activity. Its straightforward construction process and cost-effectiveness provide significant advantages for a wide range of building projects. Reinforced concrete's ability to accommodate design changes during construction enhances flexibility and adaptability on site.

Benefits of Prestressed Concrete

Prestressed concrete offers superior load-bearing capacity and enhanced durability compared to reinforced concrete, reducing the risk of cracking under tension. The prestressing process allows for longer spans and thinner slabs, optimizing material usage and lowering overall construction costs. Its improved resistance to environmental stressors results in increased structural lifespan and reduced maintenance requirements.

Limitations and Drawbacks of Each Type

Reinforced concrete faces limitations such as increased susceptibility to cracking under tensile stress and requires larger cross-sectional areas to bear heavy loads, leading to bulkier structures. Prestressed concrete, while offering enhanced strength and reduced cracking, involves higher initial costs and complex design requirements, making it less suitable for small-scale or low-budget projects. Both types demand careful attention to corrosion protection of steel components to ensure durability and long-term performance.

Cost Considerations and Economic Impact

Reinforced concrete generally incurs lower initial material and labor costs compared to prestressed concrete, making it more suitable for budget-conscious projects. Prestressed concrete, despite higher upfront expenses due to specialized materials and tensioning processes, offers long-term economic benefits through reduced maintenance and enhanced durability. Cost-benefit analysis often favors prestressed concrete in large-scale or infrastructure projects where lifespan and performance decrease total life cycle costs.

Choosing the Right Concrete Type for Your Project

Reinforced concrete combines steel reinforcement bars with concrete to resist tension and compression, making it ideal for everyday structural applications requiring durability and cost-efficiency. Prestressed concrete involves tensioning steel tendons before concrete curing, enhancing load capacity and crack resistance for long-span bridges and high-load structures. Selecting the right concrete type depends on project requirements such as span length, load demands, budget constraints, and environmental factors.

Reinforced Concrete vs Prestressed Concrete Infographic

materialdif.com

materialdif.com