Glass Fiber Reinforced Concrete (GFRC) offers exceptional tensile strength and durability due to the integration of fine glass fibers, making it ideal for architectural panels and thin sections. Polymer Modified Concrete (PMC) enhances adhesion, flexibility, and chemical resistance by incorporating polymers into the mix, improving performance in harsh environments and reducing permeability. Both materials optimize concrete properties but differ in reinforcement mechanisms, with GFRC focusing on fiber reinforcement and PMC on polymer enhancement.

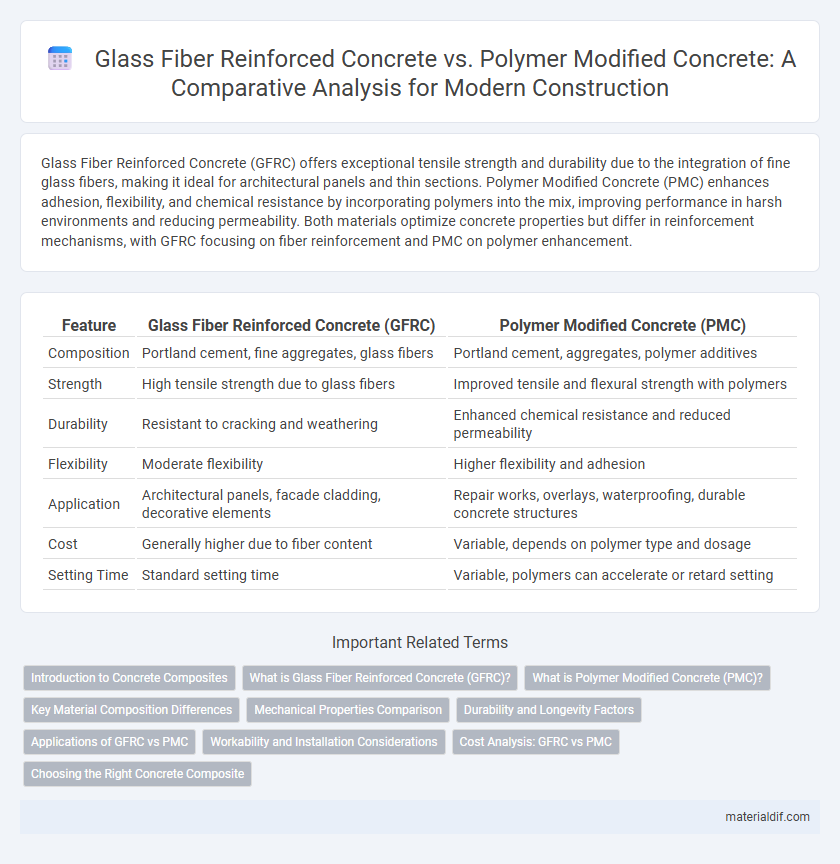

Table of Comparison

| Feature | Glass Fiber Reinforced Concrete (GFRC) | Polymer Modified Concrete (PMC) |

|---|---|---|

| Composition | Portland cement, fine aggregates, glass fibers | Portland cement, aggregates, polymer additives |

| Strength | High tensile strength due to glass fibers | Improved tensile and flexural strength with polymers |

| Durability | Resistant to cracking and weathering | Enhanced chemical resistance and reduced permeability |

| Flexibility | Moderate flexibility | Higher flexibility and adhesion |

| Application | Architectural panels, facade cladding, decorative elements | Repair works, overlays, waterproofing, durable concrete structures |

| Cost | Generally higher due to fiber content | Variable, depends on polymer type and dosage |

| Setting Time | Standard setting time | Variable, polymers can accelerate or retard setting |

Introduction to Concrete Composites

Glass Fiber Reinforced Concrete (GFRC) and Polymer Modified Concrete (PMC) represent advanced concrete composites designed to enhance durability, tensile strength, and resistance to cracking. GFRC incorporates alkali-resistant glass fibers that improve structural performance and impact resistance, making it ideal for facade panels and architectural elements. In contrast, PMC integrates polymer resins to increase bonding, reduce permeability, and improve flexibility, which is beneficial for repair applications and environments exposed to chemical attack.

What is Glass Fiber Reinforced Concrete (GFRC)?

Glass Fiber Reinforced Concrete (GFRC) is a composite material consisting of a cementitious matrix reinforced with alkali-resistant glass fibers, enhancing tensile strength and durability while reducing weight compared to traditional concrete. GFRC exhibits superior resistance to cracking, impact, weathering, and fire, making it ideal for architectural panels, facade elements, and decorative components. Its versatility allows complex shapes and thin sections, improving design flexibility and structural performance in modern construction.

What is Polymer Modified Concrete (PMC)?

Polymer Modified Concrete (PMC) is a composite material where polymers such as latex, epoxy, or acrylics are added to the concrete mix to enhance durability, flexibility, and adhesion. PMC offers improved resistance to chemical attacks, reduced permeability, and better tensile strength compared to traditional concrete. This modification makes PMC ideal for applications requiring higher performance under aggressive environmental conditions.

Key Material Composition Differences

Glass Fiber Reinforced Concrete (GFRC) incorporates alkali-resistant glass fibers dispersed throughout the cement matrix to enhance tensile strength and crack resistance, while Polymer Modified Concrete (PMC) integrates polymer resins such as acrylics, styrene-butadiene rubber, or epoxy to improve adhesion, flexibility, and chemical resistance. GFRC relies primarily on cement, sand, and glass fibers without significant alteration to the cementitious binder, whereas PMC modifies the concrete binder itself by adding polymers that form a continuous film within the matrix, altering hydration and mechanical properties. The presence of discrete glass fibers in GFRC provides reinforcing microstructure, in contrast to the polymer film in PMC that modifies the matrix's microstructure to achieve improved durability and reduced permeability.

Mechanical Properties Comparison

Glass Fiber Reinforced Concrete (GFRC) offers superior tensile strength and impact resistance compared to Polymer Modified Concrete (PMC), making it ideal for structural elements requiring enhanced durability. PMC demonstrates improved flexural strength and reduced permeability, enhancing resistance to chemical attacks and freeze-thaw cycles. Mechanical testing indicates GFRC exhibits higher modulus of elasticity, while PMC provides better bonding with substrates, influencing performance in different construction applications.

Durability and Longevity Factors

Glass Fiber Reinforced Concrete (GFRC) exhibits superior durability due to its enhanced tensile strength and resistance to cracking caused by environmental stressors, extending the lifespan of structural elements. Polymer Modified Concrete (PMC) offers improved impermeability and chemical resistance, reducing water penetration and mitigating deterioration from freeze-thaw cycles and corrosive agents. GFRC is typically preferred for architectural applications requiring flexibility and impact resistance, while PMC excels in environments with harsh chemical exposure, making both materials crucial for longevity depending on specific project requirements.

Applications of GFRC vs PMC

Glass Fiber Reinforced Concrete (GFRC) is extensively used in architectural cladding, lightweight facade panels, and decorative exterior applications due to its high tensile strength and flexibility. Polymer Modified Concrete (PMC) finds primary use in repair works, flooring solutions, and waterproofing applications because of its enhanced adhesion, chemical resistance, and durability. While GFRC excels in aesthetic and structural versatility for building exteriors, PMC is optimal for protective and maintenance roles in infrastructure projects.

Workability and Installation Considerations

Glass Fiber Reinforced Concrete (GFRC) offers enhanced workability due to its lightweight composition and high flexibility, allowing for intricate shapes and thin sections in installation. Polymer Modified Concrete (PMC) improves adhesion and reduces permeability, yet typically requires more precise mixing and curing conditions to achieve optimal performance. Both materials demand skilled labor, but GFRC generally facilitates faster application and easier handling on site compared to the more sensitive installation process of PMC.

Cost Analysis: GFRC vs PMC

Glass Fiber Reinforced Concrete (GFRC) generally incurs higher initial material costs due to the specialized glass fibers and more complex production process compared to Polymer Modified Concrete (PMC). PMC offers cost advantages with lower material expenses and simpler mixing, but long-term durability and maintenance costs can be higher in harsh environments. Evaluating the total lifecycle cost reveals that GFRC's premium upfront investment often results in better value through enhanced strength and reduced maintenance over time.

Choosing the Right Concrete Composite

Glass Fiber Reinforced Concrete (GFRC) combines high tensile strength and durability, making it ideal for architectural panels and thin-walled structures requiring enhanced flexural performance. Polymer Modified Concrete (PMC) improves adhesion, chemical resistance, and impermeability, suitable for repair works, overlays, and harsh environmental conditions. Selecting the right concrete composite depends on specific project requirements such as structural flexibility, exposure conditions, and desired longevity.

Glass Fiber Reinforced Concrete vs Polymer Modified Concrete Infographic

materialdif.com

materialdif.com