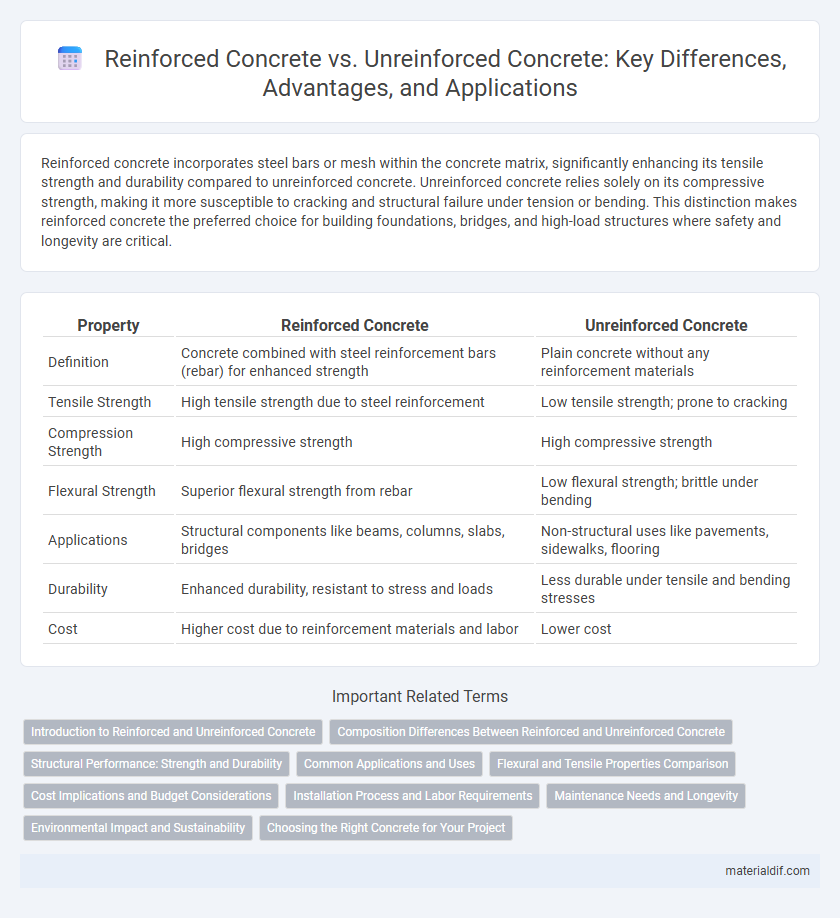

Reinforced concrete incorporates steel bars or mesh within the concrete matrix, significantly enhancing its tensile strength and durability compared to unreinforced concrete. Unreinforced concrete relies solely on its compressive strength, making it more susceptible to cracking and structural failure under tension or bending. This distinction makes reinforced concrete the preferred choice for building foundations, bridges, and high-load structures where safety and longevity are critical.

Table of Comparison

| Property | Reinforced Concrete | Unreinforced Concrete |

|---|---|---|

| Definition | Concrete combined with steel reinforcement bars (rebar) for enhanced strength | Plain concrete without any reinforcement materials |

| Tensile Strength | High tensile strength due to steel reinforcement | Low tensile strength; prone to cracking |

| Compression Strength | High compressive strength | High compressive strength |

| Flexural Strength | Superior flexural strength from rebar | Low flexural strength; brittle under bending |

| Applications | Structural components like beams, columns, slabs, bridges | Non-structural uses like pavements, sidewalks, flooring |

| Durability | Enhanced durability, resistant to stress and loads | Less durable under tensile and bending stresses |

| Cost | Higher cost due to reinforcement materials and labor | Lower cost |

Introduction to Reinforced and Unreinforced Concrete

Reinforced concrete integrates steel bars or meshes to enhance tensile strength, making it ideal for structural applications requiring durability and flexibility. Unreinforced concrete lacks these metal reinforcements, resulting in higher compressive strength but limited resistance to tension and bending forces. Understanding the distinct mechanical properties and usage scenarios of both types is essential for effective construction design and safety.

Composition Differences Between Reinforced and Unreinforced Concrete

Reinforced concrete consists of a concrete matrix combined with steel reinforcement bars or mesh, enhancing its tensile strength and ductility compared to unreinforced concrete, which lacks such metal additives. The composition of reinforced concrete includes Portland cement, aggregates (sand and gravel), water, and steel reinforcement, while unreinforced concrete typically contains only cement, aggregates, and water. This fundamental difference in composition significantly impacts structural performance, with reinforced concrete being preferred for load-bearing and seismic-resistant applications.

Structural Performance: Strength and Durability

Reinforced concrete significantly outperforms unreinforced concrete in structural performance due to the addition of steel reinforcement, which enhances tensile strength and resists cracking under stress. This composite material provides superior durability in various environmental conditions, reducing the risk of structural failure caused by tension or bending forces. Unreinforced concrete, while strong in compression, is prone to brittle failure and limited in applications where tensile and flexural stresses are critical.

Common Applications and Uses

Reinforced concrete is widely used in structural applications such as bridges, high-rise buildings, and industrial floors due to its enhanced tensile strength provided by steel reinforcement. Unreinforced concrete is typically employed in non-structural applications like sidewalks, driveways, and patios where tensile stresses are minimal. Understanding the material properties allows engineers to select the appropriate concrete type based on load-bearing requirements and environmental conditions.

Flexural and Tensile Properties Comparison

Reinforced concrete significantly outperforms unreinforced concrete in flexural strength due to the inclusion of steel rebars, which provide enhanced tensile resistance and prevent cracking under bending stress. Unreinforced concrete, primarily strong in compression but weak in tension, often fails prematurely when subjected to flexural loads because it cannot accommodate tensile forces effectively. The integration of reinforcement materials in reinforced concrete allows it to absorb and distribute tensile stresses, improving durability and structural integrity in bending applications.

Cost Implications and Budget Considerations

Reinforced concrete typically involves higher initial costs due to the use of steel rebar and labor-intensive installation, impacting overall budget allocation. Unreinforced concrete offers a lower upfront expense but may incur increased maintenance and repair costs over time, particularly in structures subject to tension or heavy loads. Budget considerations must weigh immediate material and labor expenses against long-term durability and safety requirements to determine the most cost-effective choice.

Installation Process and Labor Requirements

Reinforced concrete installation involves placing steel rebar or mesh within the formwork before pouring concrete, requiring skilled labor for precise alignment and securing of reinforcement. Unreinforced concrete's installation process is simpler, involving direct pouring into forms without the additional step of reinforcement placement, resulting in lower labor intensity and shorter time frames. The need for specialized knowledge in handling and positioning steel reinforcement significantly increases labor requirements and installation complexity in reinforced concrete projects.

Maintenance Needs and Longevity

Reinforced concrete exhibits enhanced durability and requires less frequent maintenance compared to unreinforced concrete due to its embedded steel reinforcement, which improves load-bearing capacity and crack resistance. Unreinforced concrete is more susceptible to cracking and structural degradation over time, necessitating more regular inspections and repairs. Longevity of reinforced concrete structures often exceeds 50 years with minimal upkeep, while unreinforced concrete typically has a shorter lifespan and higher maintenance demands.

Environmental Impact and Sustainability

Reinforced concrete, incorporating steel bars, significantly increases the material's carbon footprint due to steel production's high energy consumption and emissions compared to unreinforced concrete. Unreinforced concrete offers a lower environmental impact by relying solely on cement, aggregates, and water, reducing embodied energy and potential pollutant generation. Sustainable alternatives in reinforced concrete, such as recycled steel and supplementary cementitious materials, help mitigate environmental impacts and improve lifecycle sustainability.

Choosing the Right Concrete for Your Project

Reinforced concrete incorporates steel bars or mesh, significantly enhancing its tensile strength and making it ideal for structural elements like beams, columns, and slabs in buildings and bridges. Unreinforced concrete, lacking internal steel reinforcement, suits applications where compressive strength suffices, such as sidewalks, driveways, and non-load-bearing walls. Selecting the right concrete depends on load requirements, environmental conditions, and project longevity, with reinforced concrete preferred for high-stress constructions and unreinforced concrete for simpler, cost-effective uses.

Reinforced Concrete vs Unreinforced Concrete Infographic

materialdif.com

materialdif.com