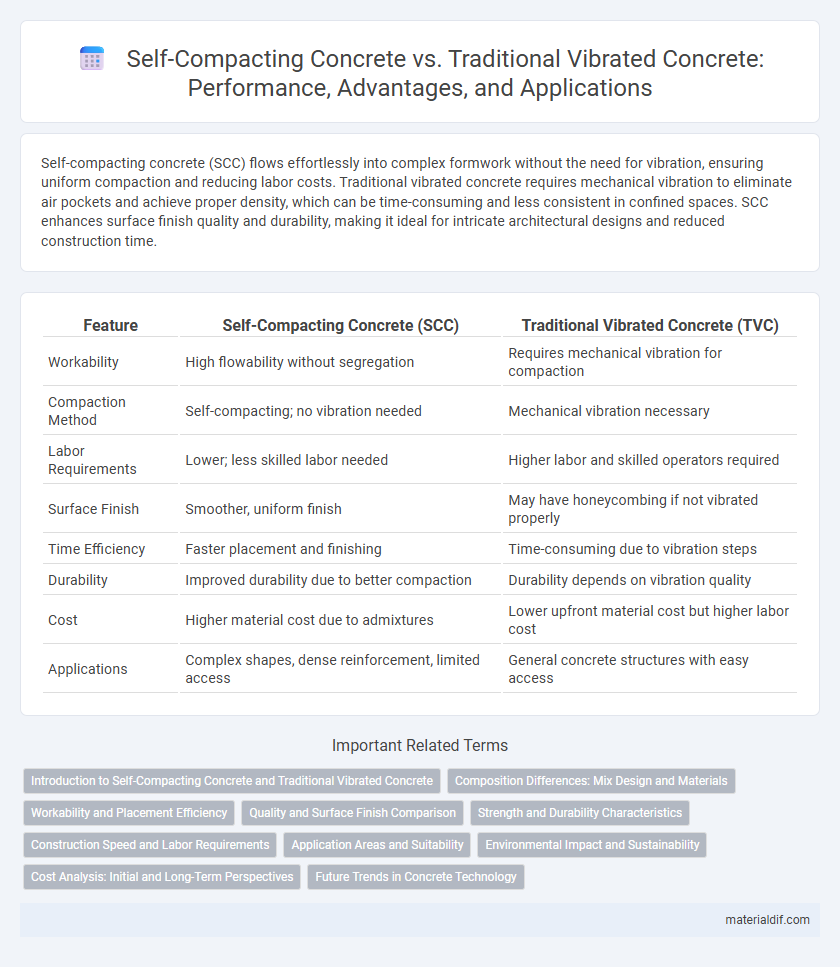

Self-compacting concrete (SCC) flows effortlessly into complex formwork without the need for vibration, ensuring uniform compaction and reducing labor costs. Traditional vibrated concrete requires mechanical vibration to eliminate air pockets and achieve proper density, which can be time-consuming and less consistent in confined spaces. SCC enhances surface finish quality and durability, making it ideal for intricate architectural designs and reduced construction time.

Table of Comparison

| Feature | Self-Compacting Concrete (SCC) | Traditional Vibrated Concrete (TVC) |

|---|---|---|

| Workability | High flowability without segregation | Requires mechanical vibration for compaction |

| Compaction Method | Self-compacting; no vibration needed | Mechanical vibration necessary |

| Labor Requirements | Lower; less skilled labor needed | Higher labor and skilled operators required |

| Surface Finish | Smoother, uniform finish | May have honeycombing if not vibrated properly |

| Time Efficiency | Faster placement and finishing | Time-consuming due to vibration steps |

| Durability | Improved durability due to better compaction | Durability depends on vibration quality |

| Cost | Higher material cost due to admixtures | Lower upfront material cost but higher labor cost |

| Applications | Complex shapes, dense reinforcement, limited access | General concrete structures with easy access |

Introduction to Self-Compacting Concrete and Traditional Vibrated Concrete

Self-compacting concrete (SCC) is a highly flowable, non-segregating concrete that spreads into place under its own weight, filling formwork and encapsulating reinforcement without mechanical vibration. Traditional vibrated concrete requires external vibration to eliminate air pockets and improve compaction, ensuring strength and durability. SCC improves construction efficiency and reduces noise pollution compared to vibrated concrete, making it ideal for complex structures and congested reinforcement layouts.

Composition Differences: Mix Design and Materials

Self-compacting concrete (SCC) utilizes a highly flowable mix design with increased fines content, superplasticizers, and viscosity-modifying admixtures to ensure its ability to flow and compact under its own weight without vibration. Traditional vibrated concrete typically contains a coarser aggregate gradation with lower fines and relies on mechanical vibration to eliminate air pockets and achieve consolidation. The higher paste volume and optimized particle packing in SCC reduce the need for external compaction while enhancing surface finish quality compared to traditional vibrated concrete.

Workability and Placement Efficiency

Self-compacting concrete (SCC) offers superior workability compared to traditional vibrated concrete, flowing effortlessly into complex formworks without the need for mechanical vibration. This high fluidity reduces labor time and minimizes the risk of honeycombing or voids, enhancing placement efficiency on construction sites. SCC's ability to fill intricate spaces with consistent compaction improves overall structural quality and accelerates project timelines.

Quality and Surface Finish Comparison

Self-compacting concrete (SCC) consistently delivers superior quality with uniform compaction and eliminates voids, resulting in enhanced durability compared to traditional vibrated concrete, which relies on mechanical vibration and may develop honeycombing or segregation if not properly handled. SCC provides a smoother, defect-free surface finish due to its high flowability and stability, reducing the need for surface repairs and extensive finishing work. Traditional vibrated concrete often requires additional surface treatment to achieve comparable aesthetics, increasing labor costs and time.

Strength and Durability Characteristics

Self-compacting concrete (SCC) exhibits superior strength due to its uniformly dense microstructure, reducing voids and enhancing load-bearing capacity compared to traditional vibrated concrete (TVC). The durability of SCC is heightened by its reduced permeability, which minimizes ingress of harmful agents like chlorides and sulfates, thereby prolonging structural lifespan. In contrast, TVC relies on mechanical vibration to consolidate, which can lead to inconsistent compaction and potential weaknesses affecting long-term performance.

Construction Speed and Labor Requirements

Self-compacting concrete (SCC) significantly accelerates construction speed by eliminating the need for mechanical vibration, allowing faster placement and immediate finishing. SCC reduces labor requirements as it requires fewer workers for compaction and minimizes the risk of improper consolidation, leading to higher quality and consistency. Traditional vibrated concrete demands skilled labor for effective vibration, increasing both labor costs and time on-site.

Application Areas and Suitability

Self-compacting concrete (SCC) excels in complex formworks and densely reinforced structures, making it highly suitable for bridges, high-rise buildings, and precast elements where vibration is difficult or labor-intensive. Traditional vibrated concrete (TVC) remains effective in standard construction applications such as pavements, foundations, and slabs where mechanical compaction is feasible and cost-efficiency is prioritized. The choice between SCC and TVC depends on project complexity, reinforcement density, and casting environment to optimize structural integrity and labor productivity.

Environmental Impact and Sustainability

Self-compacting concrete (SCC) reduces energy consumption and noise pollution by eliminating the need for mechanical vibration, leading to a lower environmental footprint compared to traditional vibrated concrete (TVC). SCC enhances material efficiency through optimized mix designs that minimize cement content and reduce CO2 emissions associated with cement production. The use of SCC promotes sustainability by enabling faster construction cycles, reducing waste, and improving durability, which extends the lifespan of structures and lowers resource demand over time.

Cost Analysis: Initial and Long-Term Perspectives

Self-compacting concrete (SCC) often incurs higher initial costs due to specialized admixtures and mix design requirements compared to traditional vibrated concrete, which relies more on labor-intensive vibration for compaction. Long-term savings arise from SCC's reduced labor expenses, faster construction times, and enhanced durability, which lowers maintenance and repair costs over the structure's lifecycle. In contrast, traditional vibrated concrete may involve ongoing quality control challenges and potential defects that increase lifecycle costs despite cheaper upfront materials.

Future Trends in Concrete Technology

Self-compacting concrete (SCC) is poised to transform the construction industry with its superior flowability and reduced labor requirements compared to traditional vibrated concrete. Advances in nano-materials and artificial intelligence integration are enhancing SCC's durability and predictive performance, making it a key focus in future concrete technology. Sustainability efforts prioritize eco-friendly SCC formulations that minimize carbon footprint while maintaining structural integrity in complex architectural designs.

Self-Compacting Concrete vs Traditional Vibrated Concrete Infographic

materialdif.com

materialdif.com