High-strength concrete offers significantly greater compressive strength compared to standard concrete, making it ideal for structures requiring enhanced durability and load-bearing capacity. Its improved resistance to environmental factors and reduced permeability ensure longer lifespan and better performance in harsh conditions. While more expensive and requiring precise mixing, high-strength concrete delivers superior structural integrity and longevity over standard concrete.

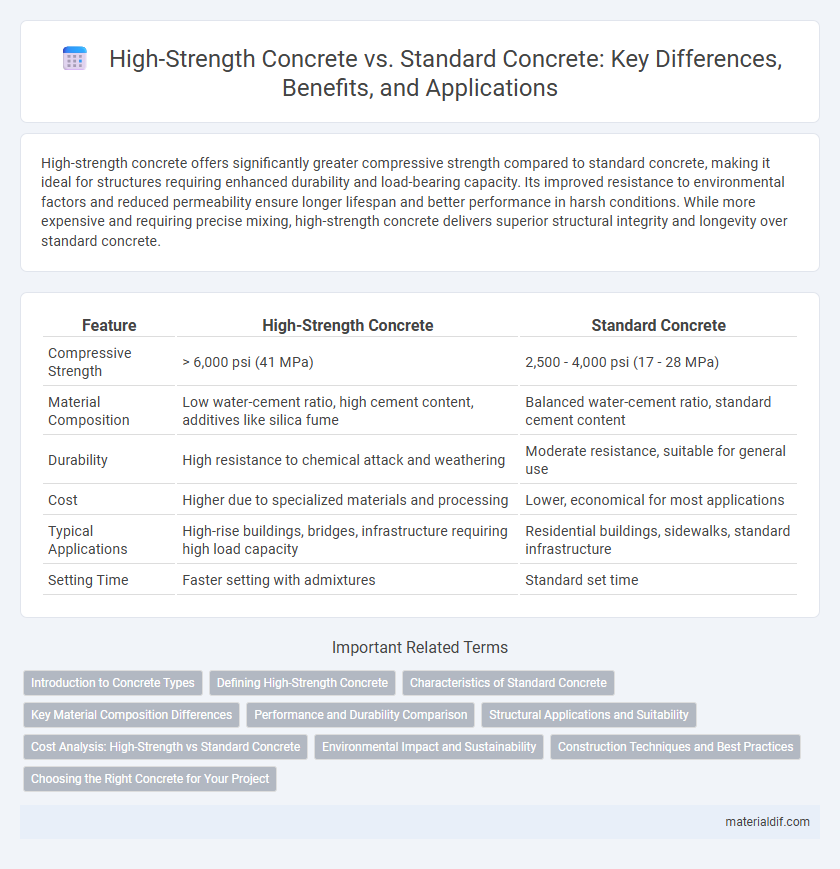

Table of Comparison

| Feature | High-Strength Concrete | Standard Concrete |

|---|---|---|

| Compressive Strength | > 6,000 psi (41 MPa) | 2,500 - 4,000 psi (17 - 28 MPa) |

| Material Composition | Low water-cement ratio, high cement content, additives like silica fume | Balanced water-cement ratio, standard cement content |

| Durability | High resistance to chemical attack and weathering | Moderate resistance, suitable for general use |

| Cost | Higher due to specialized materials and processing | Lower, economical for most applications |

| Typical Applications | High-rise buildings, bridges, infrastructure requiring high load capacity | Residential buildings, sidewalks, standard infrastructure |

| Setting Time | Faster setting with admixtures | Standard set time |

Introduction to Concrete Types

High-strength concrete is designed with a compressive strength typically above 6,000 psi, making it ideal for demanding structural applications such as high-rise buildings and long-span bridges. Standard concrete, generally ranging from 2,500 to 4,000 psi, is commonly used for sidewalks, driveways, and residential construction due to its adequate durability and cost-effectiveness. The key difference lies in material composition, where high-strength concrete incorporates advanced admixtures and lower water-cement ratios to achieve superior performance and longevity.

Defining High-Strength Concrete

High-strength concrete is defined by its compressive strength exceeding 6,000 psi (pounds per square inch), significantly higher than standard concrete, which typically ranges between 3,000 and 5,000 psi. This enhanced strength is achieved through optimized mix design, using low water-cement ratios, supplementary cementitious materials like silica fume, and high-quality aggregates. High-strength concrete is ideal for structural applications requiring superior load-bearing capacity, durability, and reduced section sizes.

Characteristics of Standard Concrete

Standard concrete typically has a compressive strength ranging from 20 to 40 MPa, making it suitable for general construction purposes such as residential buildings, sidewalks, and driveways. It possesses moderate durability and workability, with a typical water-cement ratio of around 0.45 to 0.60, which influences its porosity and long-term strength. Standard concrete sets at a normal rate without requiring specialized curing methods and is cost-effective compared to high-strength concrete options.

Key Material Composition Differences

High-strength concrete contains a higher proportion of cement and fine aggregates with a reduced water-cement ratio, resulting in enhanced compressive strength typically above 6,000 psi. The inclusion of supplementary cementitious materials such as silica fume or fly ash improves particle packing and durability compared to standard concrete, which generally has a compressive strength of 3,000 to 5,000 psi. Chemical admixtures like superplasticizers are frequently used in high-strength concrete to maintain workability despite lower water content.

Performance and Durability Comparison

High-strength concrete, with compressive strengths typically above 6,000 psi, exhibits superior performance in load-bearing capacity and resistance to environmental stress compared to standard concrete, which generally ranges from 2,500 to 4,000 psi. High-strength concrete enhances durability through reduced permeability, minimizing the infiltration of water and harmful chemicals, which extends the lifespan of infrastructure. Standard concrete often requires thicker sections and additional maintenance due to its lower resistance to freeze-thaw cycles and chemical attack, making high-strength concrete a preferred choice for critical structural applications.

Structural Applications and Suitability

High-strength concrete, characterized by compressive strengths exceeding 6,000 psi, offers superior durability and load-bearing capacity ideal for high-rise buildings, bridges, and heavy infrastructure. Standard concrete, typically ranging from 2,500 to 4,000 psi, remains suitable for residential construction and non-critical structural elements where cost-efficiency and ease of use are prioritized. Selecting the appropriate concrete type depends on design requirements, with high-strength concrete favored for complex structural applications demanding enhanced performance and longevity.

Cost Analysis: High-Strength vs Standard Concrete

High-strength concrete typically costs 20-30% more per cubic meter than standard concrete due to its specialized materials and mix design. The increased upfront investment is often offset by reduced structural dimensions and longer lifespan, leading to lower maintenance costs over time. Projects with demanding performance requirements benefit economically from high-strength concrete despite its higher initial price.

Environmental Impact and Sustainability

High-strength concrete reduces material consumption due to its superior load-bearing capacity, resulting in lower carbon emissions per unit of structural performance compared to standard concrete. The production of high-strength concrete often requires supplementary cementitious materials like fly ash or slag, which enhance sustainability by utilizing industrial by-products and reducing Portland cement demand. Despite its higher initial embodied energy, the extended lifespan and decreased maintenance needs of high-strength concrete contribute to a significantly lower environmental footprint over a building's lifecycle.

Construction Techniques and Best Practices

High-strength concrete requires precise mixing ratios, typically involving lower water-cement ratios and the inclusion of supplementary cementitious materials like silica fume for enhanced durability. Construction techniques emphasize meticulous curing processes and the use of advanced compaction methods such as vibration to prevent voids and ensure uniform density. Best practices include rigorous quality control, tailored formwork to manage higher stiffness, and adherence to specific guidelines for placing and finishing to optimize structural performance.

Choosing the Right Concrete for Your Project

High-strength concrete offers compressive strengths exceeding 6,000 psi, making it ideal for infrastructure requiring superior durability and load-bearing capacity, such as bridges and high-rise buildings. Standard concrete, typically ranging from 2,500 to 4,000 psi, suits residential projects and sidewalks where moderate strength suffices, balancing cost and performance. Selecting the appropriate concrete depends on project demands, environmental conditions, and structural specifications to ensure longevity and safety.

High-Strength Concrete vs Standard Concrete Infographic

materialdif.com

materialdif.com