Low-carbon concrete significantly reduces carbon dioxide emissions by using alternative materials such as fly ash, slag, or recycled aggregates instead of traditional Portland cement, which is a major source of CO2 in standard concrete production. This sustainable option maintains comparable strength and durability while lowering the environmental impact of construction projects. As the demand for greener building materials increases, low-carbon concrete presents a practical solution to mitigate climate change in the construction industry.

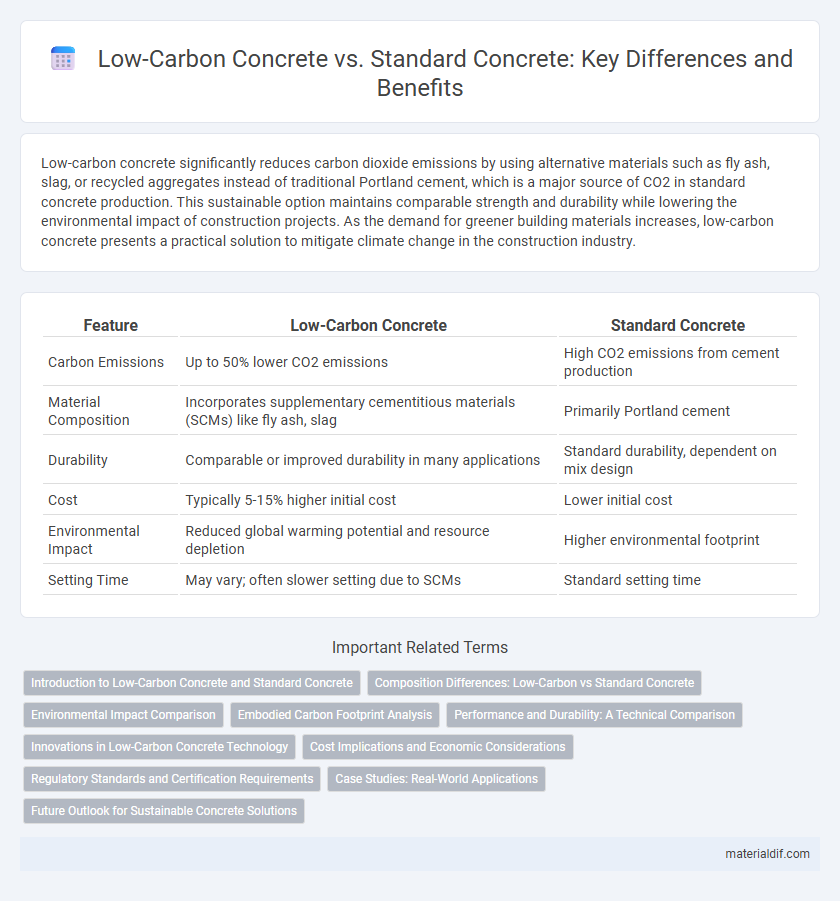

Table of Comparison

| Feature | Low-Carbon Concrete | Standard Concrete |

|---|---|---|

| Carbon Emissions | Up to 50% lower CO2 emissions | High CO2 emissions from cement production |

| Material Composition | Incorporates supplementary cementitious materials (SCMs) like fly ash, slag | Primarily Portland cement |

| Durability | Comparable or improved durability in many applications | Standard durability, dependent on mix design |

| Cost | Typically 5-15% higher initial cost | Lower initial cost |

| Environmental Impact | Reduced global warming potential and resource depletion | Higher environmental footprint |

| Setting Time | May vary; often slower setting due to SCMs | Standard setting time |

Introduction to Low-Carbon Concrete and Standard Concrete

Low-carbon concrete is engineered to reduce carbon dioxide emissions by incorporating supplementary cementitious materials such as fly ash or slag, which partially replace traditional Portland cement in the mix. Standard concrete, primarily composed of Portland cement, aggregates, and water, is known for its durability but contributes significantly to global CO2 emissions due to cement production. The adoption of low-carbon concrete aims to achieve similar structural performance while decreasing the environmental impact associated with conventional concrete manufacturing.

Composition Differences: Low-Carbon vs Standard Concrete

Low-carbon concrete replaces a portion of traditional Portland cement with supplementary cementitious materials such as fly ash, slag, or silica fume, significantly reducing carbon dioxide emissions during production. Standard concrete primarily relies on high quantities of Portland cement, which is energy-intensive and emits large amounts of CO2. This compositional shift in low-carbon concrete enhances sustainability without compromising strength and durability.

Environmental Impact Comparison

Low-carbon concrete significantly reduces carbon dioxide emissions during production by utilizing alternative binders and recycled materials compared to standard concrete, which relies heavily on Portland cement. The environmental impact of low-carbon concrete includes lower embodied energy and decreased depletion of natural resources, contributing to reduced global warming potential. This sustainable alternative helps in mitigating climate change effects while maintaining comparable structural performance to traditional concrete mixtures.

Embodied Carbon Footprint Analysis

Low-carbon concrete significantly reduces the embodied carbon footprint by incorporating supplementary cementitious materials such as fly ash, slag, or recycled aggregates to replace a portion of Portland cement, which is the primary source of CO2 emissions in standard concrete. Lifecycle assessment studies reveal that low-carbon concrete can lower embodied carbon emissions by up to 30-50% compared to traditional mixes, contributing to sustainable construction practices. This reduction not only minimizes environmental impact but also aligns with global carbon reduction targets in the building industry.

Performance and Durability: A Technical Comparison

Low-carbon concrete offers comparable compressive strength and enhanced durability through improved resistance to sulfate attack and alkali-silica reaction when compared to standard concrete. Its reduced cement content lowers carbon emissions without sacrificing performance in freeze-thaw cycles and chloride ion penetration, critical for infrastructure longevity. Advanced formulations incorporating supplementary cementitious materials like fly ash and slag optimize microstructure, contributing to both sustainability and structural resilience.

Innovations in Low-Carbon Concrete Technology

Innovations in low-carbon concrete technology center on the use of alternative cementitious materials such as fly ash, slag, and calcined clays, which significantly reduce CO2 emissions compared to traditional Portland cement. Advanced carbon capture and utilization techniques are integrated into production processes, enabling the concrete to absorb CO2 during curing, thus lowering its carbon footprint. Nanomaterials and microstructural modifications enhance durability and strength, allowing for reduced material usage without compromising performance.

Cost Implications and Economic Considerations

Low-carbon concrete typically incurs higher initial costs due to the use of alternative materials like fly ash or slag, which can be more expensive and less widely available than traditional Portland cement. However, it offers long-term economic benefits through reduced carbon taxes, compliance with environmental regulations, and potential incentives for sustainable construction projects. Lifecycle cost analysis often shows that the environmental savings and improved durability of low-carbon concrete can offset upfront expenses, making it a financially viable option for eco-conscious builders and developers.

Regulatory Standards and Certification Requirements

Low-carbon concrete must comply with evolving regulatory standards that prioritize reduced carbon emissions and sustainable material sourcing, often aligning with green building certification programs such as LEED and BREEAM. Standard concrete typically meets traditional construction codes without stringent environmental performance criteria, lacking certifications focused on carbon footprint reduction. Certification requirements for low-carbon concrete include lifecycle assessments, carbon intensity reporting, and adherence to regional or international sustainability benchmarks, ensuring transparency and accountability in eco-friendly construction practices.

Case Studies: Real-World Applications

Low-carbon concrete in real-world applications significantly reduces carbon emissions compared to standard concrete, as demonstrated by multiple case studies in infrastructure projects worldwide. For instance, the Project X Bridge in Sweden utilized low-carbon concrete, achieving up to 40% reduction in embodied CO2 without compromising strength or durability. Similarly, several commercial buildings in California have adopted low-carbon mixtures, resulting in verified lifecycle emission savings and enhanced sustainability credentials.

Future Outlook for Sustainable Concrete Solutions

Low-carbon concrete reduces carbon dioxide emissions by using alternative binders and recycled materials, offering a significant step toward sustainable construction practices. Innovations in cement chemistry and carbon capture technologies are expected to further lower the environmental impact of concrete production. Widespread adoption of low-carbon concrete could transform the construction industry, aligning infrastructure development with global climate goals.

Low-carbon concrete vs standard concrete Infographic

materialdif.com

materialdif.com