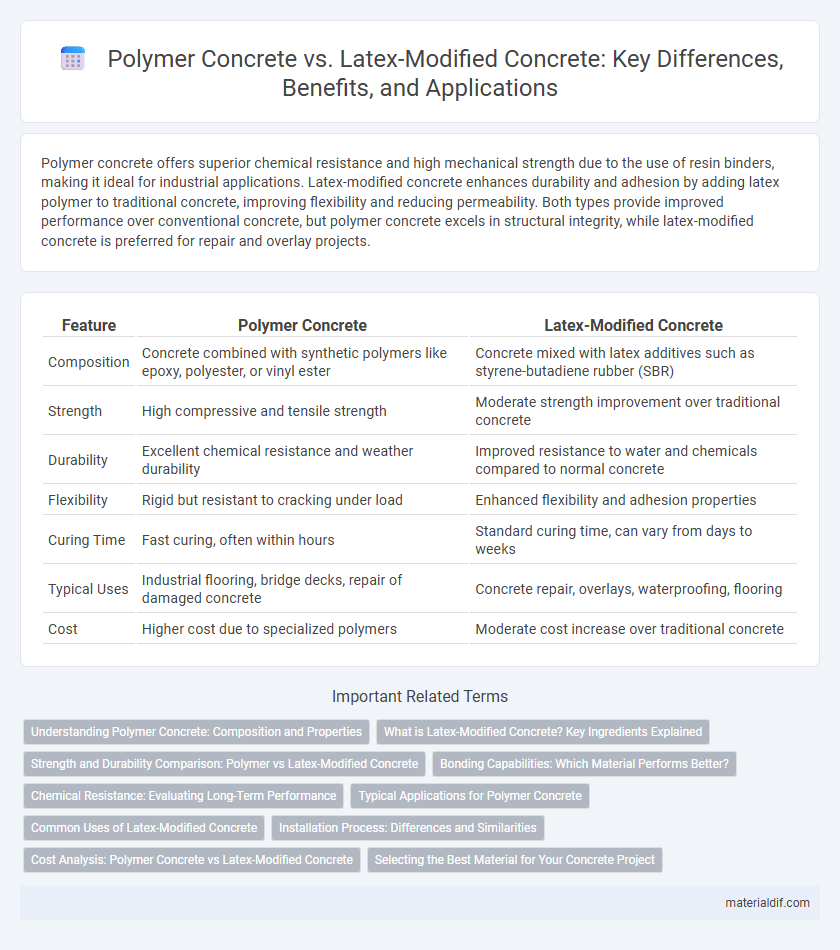

Polymer concrete offers superior chemical resistance and high mechanical strength due to the use of resin binders, making it ideal for industrial applications. Latex-modified concrete enhances durability and adhesion by adding latex polymer to traditional concrete, improving flexibility and reducing permeability. Both types provide improved performance over conventional concrete, but polymer concrete excels in structural integrity, while latex-modified concrete is preferred for repair and overlay projects.

Table of Comparison

| Feature | Polymer Concrete | Latex-Modified Concrete |

|---|---|---|

| Composition | Concrete combined with synthetic polymers like epoxy, polyester, or vinyl ester | Concrete mixed with latex additives such as styrene-butadiene rubber (SBR) |

| Strength | High compressive and tensile strength | Moderate strength improvement over traditional concrete |

| Durability | Excellent chemical resistance and weather durability | Improved resistance to water and chemicals compared to normal concrete |

| Flexibility | Rigid but resistant to cracking under load | Enhanced flexibility and adhesion properties |

| Curing Time | Fast curing, often within hours | Standard curing time, can vary from days to weeks |

| Typical Uses | Industrial flooring, bridge decks, repair of damaged concrete | Concrete repair, overlays, waterproofing, flooring |

| Cost | Higher cost due to specialized polymers | Moderate cost increase over traditional concrete |

Understanding Polymer Concrete: Composition and Properties

Polymer concrete consists of a mixture of aggregates bonded by a polymer resin binder, which replaces traditional cement, resulting in superior chemical resistance and high tensile strength. Its composition typically includes thermosetting resins such as epoxy, polyester, or vinyl ester, enhancing durability and reducing permeability compared to latent-modified concrete. These properties make polymer concrete ideal for applications requiring rapid curing, exceptional adhesion, and resistance to corrosive environments.

What is Latex-Modified Concrete? Key Ingredients Explained

Latex-Modified Concrete is a composite material that incorporates polymer latex emulsions into traditional concrete mixtures to enhance durability, flexibility, and waterproofing properties. Its key ingredients include Portland cement, fine and coarse aggregates, water, and a specialized latex polymer that improves adhesion and reduces permeability. This modification results in concrete with superior resistance to cracking, chemical attacks, and abrasion compared to conventional or polymer-only concretes.

Strength and Durability Comparison: Polymer vs Latex-Modified Concrete

Polymer concrete exhibits higher compressive strength and superior chemical resistance compared to latex-modified concrete, making it ideal for industrial applications requiring enhanced durability. Latex-modified concrete offers improved flexibility and adhesion, which enhances crack resistance but generally provides lower overall strength than polymer concrete. Both materials improve durability over traditional concrete, but polymer concrete's dense matrix delivers greater resistance to abrasion and environmental degradation.

Bonding Capabilities: Which Material Performs Better?

Polymer concrete demonstrates superior bonding capabilities compared to latex-modified concrete due to its chemical composition, which enhances adhesion to various substrates. The presence of synthetic polymers in polymer concrete creates a dense, cohesive matrix that significantly improves tensile strength and resistance to delamination. Latex-modified concrete improves flexibility and bonding compared to traditional concrete but typically exhibits lower bond strength and durability under aggressive environments than polymer concrete.

Chemical Resistance: Evaluating Long-Term Performance

Polymer concrete exhibits superior chemical resistance due to its organic polymer binder, which effectively resists acids, alkalis, and solvents over extended periods. Latex-modified concrete incorporates latex additives that enhance flexibility and reduce permeability, improving resistance but generally underperforming compared to polymer concrete in highly aggressive chemical environments. Long-term performance evaluations consistently demonstrate polymer concrete's durability in industrial applications exposed to chemical corrosion, making it the preferred choice for harsh conditions.

Typical Applications for Polymer Concrete

Polymer concrete is primarily used in applications requiring high chemical resistance and fast curing times, such as industrial flooring, corrosion-resistant pipelines, and precast concrete products. Its superior bonding strength and durability make it ideal for repair works and overlays in structures exposed to harsh environments. Unlike latex-modified concrete, polymer concrete excels in situations demanding minimal permeability and exceptional mechanical properties.

Common Uses of Latex-Modified Concrete

Latex-modified concrete is commonly used in applications requiring enhanced durability and flexibility, such as bridge deck overlays, repair of damaged concrete surfaces, and waterproofing membranes. Its improved adhesion and resistance to cracking make it ideal for protective coatings and industrial flooring. The polymer additive in latex-modified concrete enhances performance in harsh environmental conditions, extending the lifespan of structural repairs.

Installation Process: Differences and Similarities

Polymer concrete involves mixing polymers with aggregates, resulting in a fast-curing mixture that typically sets within hours, allowing for quicker installation compared to latex-modified concrete. Latex-modified concrete integrates liquid latex additives into traditional cement mixtures, enhancing adhesion and flexibility but requiring standard curing times of several days. Both materials demand meticulous surface preparation and similar application techniques, such as troweling and smoothing, to ensure optimal bonding and durability.

Cost Analysis: Polymer Concrete vs Latex-Modified Concrete

Polymer concrete typically incurs higher initial costs than latex-modified concrete due to the use of synthetic resins and specialized materials, impacting overall budget considerations. In contrast, latex-modified concrete offers a more cost-effective solution by incorporating latex additives, which enhance durability and adhesion while maintaining lower material expenses. Evaluating lifecycle costs reveals that polymer concrete may provide superior long-term performance, justifying its upfront investment in specific high-stress applications.

Selecting the Best Material for Your Concrete Project

Polymer concrete offers superior chemical resistance and enhanced tensile strength, making it ideal for industrial applications requiring durability and corrosion resistance. Latex-modified concrete improves bond strength and flexibility, which is beneficial for repair works and pavements exposed to dynamic loads. Selecting the best material depends on project-specific requirements such as environmental exposure, load conditions, and desired longevity to ensure optimal performance and cost-efficiency.

Polymer Concrete vs Latex-Modified Concrete Infographic

materialdif.com

materialdif.com