Wet-mix concrete includes a higher water content, providing better workability and uniformity, making it ideal for complex structural applications. Dry-mix concrete, or shotcrete, contains minimal water, enabling faster setting and easier placement in confined areas or vertical surfaces. The choice between wet-mix and dry-mix concrete depends on project requirements such as workability, strength, and application method.

Table of Comparison

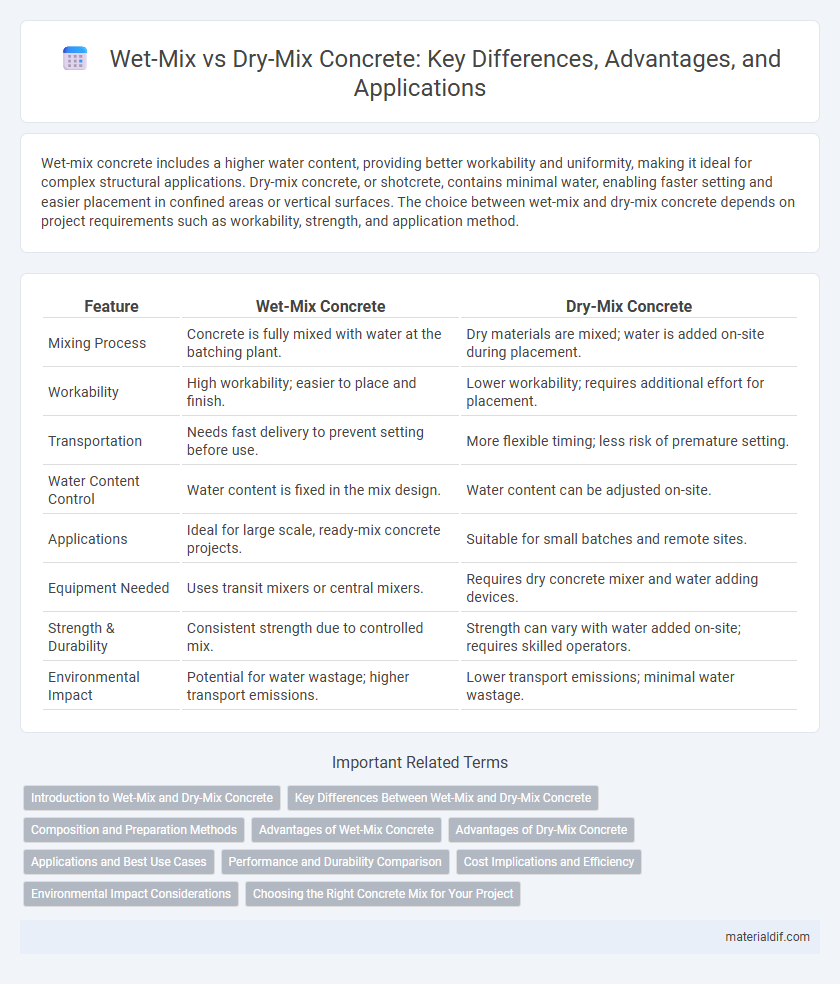

| Feature | Wet-Mix Concrete | Dry-Mix Concrete |

|---|---|---|

| Mixing Process | Concrete is fully mixed with water at the batching plant. | Dry materials are mixed; water is added on-site during placement. |

| Workability | High workability; easier to place and finish. | Lower workability; requires additional effort for placement. |

| Transportation | Needs fast delivery to prevent setting before use. | More flexible timing; less risk of premature setting. |

| Water Content Control | Water content is fixed in the mix design. | Water content can be adjusted on-site. |

| Applications | Ideal for large scale, ready-mix concrete projects. | Suitable for small batches and remote sites. |

| Equipment Needed | Uses transit mixers or central mixers. | Requires dry concrete mixer and water adding devices. |

| Strength & Durability | Consistent strength due to controlled mix. | Strength can vary with water added on-site; requires skilled operators. |

| Environmental Impact | Potential for water wastage; higher transport emissions. | Lower transport emissions; minimal water wastage. |

Introduction to Wet-Mix and Dry-Mix Concrete

Wet-mix concrete, also known as ready-mix concrete, contains a higher water-to-cement ratio, resulting in a fluid mixture that is transported in a mixer truck to the construction site for immediate use. Dry-mix concrete, or dry-batch concrete, consists of a dry blend of cement, aggregates, and additives, with water added only at the point of application, commonly employed in shotcrete or gunite processes. The choice between wet-mix and dry-mix concrete depends on factors like project size, transportation distance, and specific application requirements.

Key Differences Between Wet-Mix and Dry-Mix Concrete

Wet-mix concrete contains a predetermined amount of water and arrives at the construction site as a ready-to-use mixture, offering superior workability and uniformity. Dry-mix concrete, also known as shotcrete or gunite, involves mixing dry ingredients with water at the application site, providing faster setting time and reduced transportation weight. The key differences include moisture content, method of mixing and placing, and application suitability, with wet-mix ideal for large-scale pours and dry-mix preferred for repair work and overhead applications.

Composition and Preparation Methods

Wet-mix concrete consists of pre-mixed cement, aggregates, water, and admixtures combined at the batching plant to achieve a homogenous mixture ready for immediate use. Dry-mix concrete, also known as dry-batched concrete, involves measuring cement and aggregates at the plant and delivering the dry mix to the construction site where water is added on-site before mixing. The wet-mix method ensures consistent hydration and workability, while dry-mix allows greater flexibility in water content adjustment during placement.

Advantages of Wet-Mix Concrete

Wet-mix concrete offers superior workability and uniformity compared to dry-mix concrete, ensuring better compaction and reduced air voids. Its pre-mixed consistency enhances strength development and durability, making it ideal for structural applications like foundations and slabs. The ready-to-use nature of wet-mix concrete minimizes site labor and reduces the risk of material segregation, improving overall construction efficiency.

Advantages of Dry-Mix Concrete

Dry-mix concrete offers significant advantages including improved control over the water-to-cement ratio, leading to higher strength and durability in the finished product. Its ease of transportation and reduced risk of segregation make it ideal for remote or large-scale construction projects. Additionally, the dry-mix method minimizes waste and allows for faster mixing and placement on-site, enhancing overall efficiency.

Applications and Best Use Cases

Wet-mix concrete, with its high workability and uniform consistency, is ideal for large-scale projects like bridges, dams, and high-rise buildings requiring precise placement and strong structural integrity. Dry-mix concrete, also known as shotcrete, excels in applications such as repair works, tunneling, and slope stabilization where rapid setting and minimal water content are crucial. Selecting between wet-mix and dry-mix concrete depends on factors like project scale, placement method, and environmental conditions to ensure optimal performance and durability.

Performance and Durability Comparison

Wet-mix concrete offers superior performance with enhanced workability and uniformity, leading to higher strength and better surface finishes compared to dry-mix concrete. Its controlled water content ensures consistent curing, resulting in improved durability and resistance to environmental deterioration such as freeze-thaw cycles and chemical attacks. In contrast, dry-mix concrete often exhibits lower compressive strength and increased permeability, making it less suitable for structural applications requiring long-term resilience.

Cost Implications and Efficiency

Wet-mix concrete typically incurs higher transportation and handling costs due to its ready-to-use liquid form, requiring specialized trucks and timely delivery to prevent premature setting. Dry-mix concrete lowers upfront costs by allowing on-site water addition, enhancing flexibility and reducing wastage, but may increase labor expenses and mixing time. Efficiency gains in wet-mix concrete arise from uniform consistency and faster placement, while dry-mix offers cost savings in small-scale projects with less stringent timing constraints.

Environmental Impact Considerations

Wet-mix concrete generates lower dust emissions during production and transportation, reducing airborne particulate pollution compared to dry-mix concrete. The higher water content in wet-mix concrete can lead to increased energy consumption in curing processes but often results in better durability, potentially lowering the need for repairs and associated environmental costs. Dry-mix concrete minimizes water usage at the plant, offering advantages in water-scarce regions, yet its onsite mixing can emit more dust and cause inconsistent material performance, influencing its overall environmental footprint.

Choosing the Right Concrete Mix for Your Project

Wet-mix concrete offers higher slump and better workability, making it ideal for projects requiring complex shapes or pumping, while dry-mix concrete is favored for repairs and smaller jobs due to its rapid setting and reduced water content. The choice depends on factors like project scale, environmental conditions, and desired finish quality, with wet-mix supporting uniformity and strength, whereas dry-mix provides more control at the application site. Understanding the specific demands of your construction task ensures optimal durability and cost-efficiency by selecting the appropriate concrete mix.

Wet-Mix Concrete vs Dry-Mix Concrete Infographic

materialdif.com

materialdif.com