Fiber-reinforced concrete significantly improves durability and crack resistance compared to plain concrete by incorporating fibrous materials that enhance tensile strength and toughness. Plain concrete, while cost-effective and easy to work with, tends to be more brittle and susceptible to cracking under stress. The use of fiber reinforcement reduces maintenance needs and extends the lifespan of concrete structures, making it ideal for applications requiring enhanced performance and longevity.

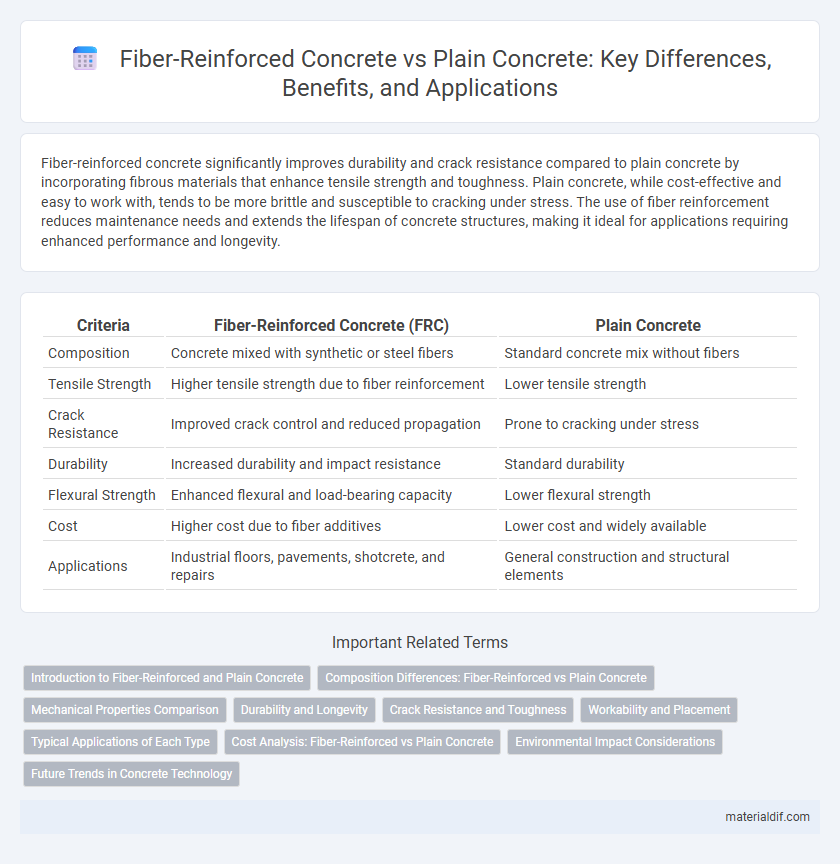

Table of Comparison

| Criteria | Fiber-Reinforced Concrete (FRC) | Plain Concrete |

|---|---|---|

| Composition | Concrete mixed with synthetic or steel fibers | Standard concrete mix without fibers |

| Tensile Strength | Higher tensile strength due to fiber reinforcement | Lower tensile strength |

| Crack Resistance | Improved crack control and reduced propagation | Prone to cracking under stress |

| Durability | Increased durability and impact resistance | Standard durability |

| Flexural Strength | Enhanced flexural and load-bearing capacity | Lower flexural strength |

| Cost | Higher cost due to fiber additives | Lower cost and widely available |

| Applications | Industrial floors, pavements, shotcrete, and repairs | General construction and structural elements |

Introduction to Fiber-Reinforced and Plain Concrete

Fiber-reinforced concrete incorporates discrete fibers such as steel, glass, or synthetic materials to enhance its tensile strength, durability, and crack resistance compared to plain concrete. Plain concrete, composed primarily of cement, water, and aggregates, relies on its compressive strength but is more susceptible to cracking and brittle failure under tensile stress. The integration of fibers in concrete provides improved mechanical properties and longevity, making fiber-reinforced concrete suitable for structural applications requiring higher performance.

Composition Differences: Fiber-Reinforced vs Plain Concrete

Fiber-reinforced concrete incorporates discrete fibers such as steel, glass, or synthetic materials uniformly distributed within the cementitious matrix, enhancing tensile strength and crack resistance. Plain concrete consists solely of cement, aggregates, and water without any fibrous additives, resulting in lower post-cracking ductility and durability. The composite nature of fiber-reinforced concrete improves mechanical properties and reduces shrinkage-induced cracking compared to conventional plain concrete.

Mechanical Properties Comparison

Fiber-reinforced concrete exhibits significantly improved tensile strength, flexural strength, and impact resistance compared to plain concrete, due to the inclusion of fibers such as steel, glass, or polypropylene which bridge cracks and control crack propagation. The addition of fibers enhances toughness and ductility, reducing brittleness and increasing energy absorption capacity under load. Plain concrete, while strong in compression, lacks these mechanical advantages, making fiber-reinforced concrete a superior choice in applications requiring enhanced durability and load-bearing performance.

Durability and Longevity

Fiber-reinforced concrete (FRC) significantly enhances durability and longevity compared to plain concrete by improving crack resistance and reducing shrinkage. The inclusion of synthetic or steel fibers increases tensile strength and prevents micro-cracks from propagating, resulting in better performance under repeated stresses and harsh environmental conditions. Studies reveal that FRC exhibits superior resistance to freeze-thaw cycles, abrasion, and corrosion, extending the service life of concrete structures.

Crack Resistance and Toughness

Fiber-reinforced concrete significantly enhances crack resistance and toughness compared to plain concrete by distributing stress more evenly through embedded fibers such as steel, glass, or synthetic materials. This reinforcement reduces micro-crack formation and controls crack propagation, leading to improved durability and structural integrity under tensile and flexural loads. Consequently, fiber-reinforced concrete outperforms plain concrete in applications requiring high impact resistance and extended service life.

Workability and Placement

Fiber-reinforced concrete exhibits enhanced toughness but often shows reduced workability compared to plain concrete due to the presence of fibers, which can interfere with flow and compaction. The addition of synthetic or steel fibers improves crack resistance during placement but requires careful adjustment of mix design to maintain proper slump and avoid segregation. Contractors must balance fiber dosage and use admixtures to ensure efficient placement while preserving the desired mechanical properties of the hardened concrete.

Typical Applications of Each Type

Fiber-reinforced concrete enhances tensile strength and crack resistance, making it ideal for industrial floors, bridge decks, and tunnels where durability and impact resistance are critical. Plain concrete is commonly used in residential foundations, sidewalks, and pavements where compressive strength is sufficient and material cost is a priority. Selecting between fiber-reinforced and plain concrete depends on application-specific requirements such as load conditions, environmental exposure, and maintenance expectations.

Cost Analysis: Fiber-Reinforced vs Plain Concrete

Fiber-reinforced concrete generally incurs higher initial costs compared to plain concrete due to the expense of synthetic or steel fibers integrated into the mix. However, the enhanced durability and reduced maintenance requirements of fiber-reinforced concrete often result in lower life-cycle costs. In applications requiring crack resistance and impact strength, the cost-effectiveness of fiber reinforcement becomes evident despite the higher upfront investment.

Environmental Impact Considerations

Fiber-reinforced concrete reduces the overall carbon footprint by enhancing durability and limiting the need for frequent repairs compared to plain concrete, which often requires more maintenance and replacements over time. The use of synthetic or natural fibers can decrease the reliance on steel reinforcement, cutting down on energy-intensive steel production emissions. Life cycle assessments indicate fiber-reinforced concrete contributes to lower long-term environmental impacts through improved crack resistance and reduced material consumption.

Future Trends in Concrete Technology

Fiber-reinforced concrete (FRC) demonstrates superior durability and crack resistance compared to plain concrete, positioning it as a key material in sustainable infrastructure development. Future trends emphasize integrating advanced fibers such as carbon, basalt, and synthetic variants to enhance tensile strength and impact resilience. Innovations in nanotechnology and smart sensing embedded in FRC aim to monitor structural health in real-time, driving the evolution towards smarter, longer-lasting concrete solutions.

Fiber-Reinforced Concrete vs Plain Concrete Infographic

materialdif.com

materialdif.com