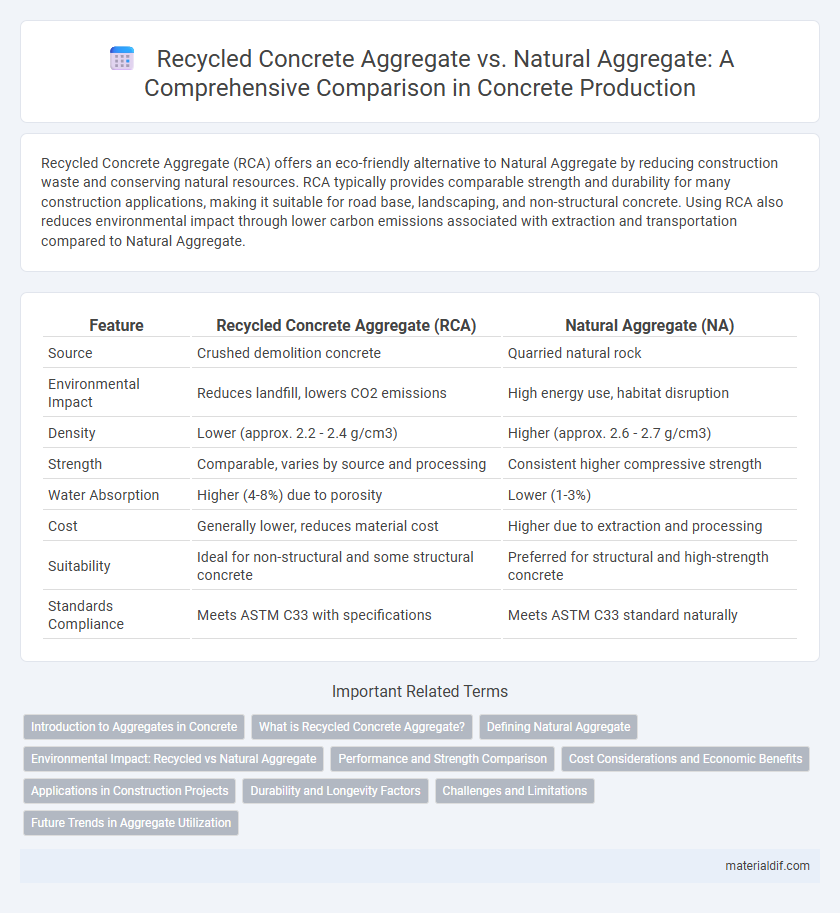

Recycled Concrete Aggregate (RCA) offers an eco-friendly alternative to Natural Aggregate by reducing construction waste and conserving natural resources. RCA typically provides comparable strength and durability for many construction applications, making it suitable for road base, landscaping, and non-structural concrete. Using RCA also reduces environmental impact through lower carbon emissions associated with extraction and transportation compared to Natural Aggregate.

Table of Comparison

| Feature | Recycled Concrete Aggregate (RCA) | Natural Aggregate (NA) |

|---|---|---|

| Source | Crushed demolition concrete | Quarried natural rock |

| Environmental Impact | Reduces landfill, lowers CO2 emissions | High energy use, habitat disruption |

| Density | Lower (approx. 2.2 - 2.4 g/cm3) | Higher (approx. 2.6 - 2.7 g/cm3) |

| Strength | Comparable, varies by source and processing | Consistent higher compressive strength |

| Water Absorption | Higher (4-8%) due to porosity | Lower (1-3%) |

| Cost | Generally lower, reduces material cost | Higher due to extraction and processing |

| Suitability | Ideal for non-structural and some structural concrete | Preferred for structural and high-strength concrete |

| Standards Compliance | Meets ASTM C33 with specifications | Meets ASTM C33 standard naturally |

Introduction to Aggregates in Concrete

Recycled concrete aggregate (RCA) is produced by crushing demolished concrete, offering an eco-friendly alternative to natural aggregate (NA) derived from quarries. Both RCA and NA serve as essential components in concrete mixtures, significantly influencing density, strength, and durability. Understanding the physical and mechanical properties of these aggregates is crucial for optimizing concrete performance in construction projects.

What is Recycled Concrete Aggregate?

Recycled Concrete Aggregate (RCA) consists of crushed concrete debris derived from demolished structures, serving as a sustainable alternative to Natural Aggregate (NA) extracted from quarries or riverbeds. RCA retains physical properties like strength and durability suitable for various construction applications, including road base layers, drainage systems, and concrete production. Utilizing RCA reduces landfill waste, conserves natural resources, and lowers environmental impact compared to traditional Natural Aggregates.

Defining Natural Aggregate

Natural aggregate consists of unprocessed materials such as sand, gravel, and crushed stone extracted directly from quarries, riverbeds, or deposits. It is characterized by its consistent composition, high strength, and durability, making it a preferred choice in traditional concrete production. The physical properties of natural aggregates, including particle size distribution and mineralogy, significantly influence the workability, strength, and longevity of concrete structures.

Environmental Impact: Recycled vs Natural Aggregate

Recycled concrete aggregate significantly reduces environmental impact by minimizing landfill waste and conserving natural resources, cutting down on the extraction-related habitat destruction and carbon emissions associated with natural aggregate. Studies show recycled aggregates can lower embodied energy by up to 40% compared to virgin aggregates, contributing to sustainable construction practices. The reuse of concrete also decreases the demand for quarrying activities, thus preserving natural landscapes and reducing dust and water pollution.

Performance and Strength Comparison

Recycled Concrete Aggregate (RCA) typically exhibits lower compressive strength and higher water absorption compared to Natural Aggregate (NA), impacting the overall concrete durability and performance. RCA's angularity and porous texture can reduce workability but enhance bonding with cement paste, which partially compensates for strength loss in structural applications. Studies show that using RCA up to 30% replacement yields comparable compressive strength to NA concrete, making it feasible for non-load-bearing and certain structural uses.

Cost Considerations and Economic Benefits

Recycled Concrete Aggregate (RCA) offers significant cost savings compared to Natural Aggregate (NA) by reducing raw material expenses and lowering transportation costs due to proximity to demolition sites. Economic benefits include reduced landfill fees, decreased demand for virgin materials, and eligibility for green building incentives, enhancing project profitability. Long-term infrastructure projects benefit from RCA's stable pricing and sustainability profile, making it a cost-effective alternative in concrete production.

Applications in Construction Projects

Recycled Concrete Aggregate (RCA) is extensively used in road base layers, embankments, and non-structural fills, offering sustainable alternatives that reduce environmental impact compared to Natural Aggregate (NA). NA remains preferred for high-strength structural concrete and architectural finishes due to superior durability and consistency in particle shape. Selection between RCA and NA depends on project-specific requirements such as load-bearing capacity, exposure conditions, and cost-efficiency in construction applications.

Durability and Longevity Factors

Recycled Concrete Aggregate (RCA) exhibits slightly lower durability than Natural Aggregate (NA) due to higher porosity and residual mortar content, which can increase water absorption and susceptibility to freeze-thaw cycles. However, advanced processing methods and proper mix design mitigate these effects, enabling RCA to achieve comparable longevity in structural applications. Studies indicate that with adequate quality control, RCA concrete can maintain long-term performance similar to NA, supporting sustainable construction practices without compromising durability.

Challenges and Limitations

Recycled Concrete Aggregate (RCA) often faces challenges such as higher porosity and increased water absorption compared to Natural Aggregate (NA), leading to potential reductions in concrete durability and strength. Variability in RCA quality due to heterogeneous source materials can result in inconsistent mechanical properties and complicate mix design optimization. Limitations also include the presence of contaminants and adhered mortar, which may negatively impact the bonding characteristics and long-term performance of concrete structures.

Future Trends in Aggregate Utilization

Recycled concrete aggregate (RCA) is gaining momentum as a sustainable alternative to natural aggregate (NA) due to increasing environmental regulations and the need for resource conservation. Advances in recycling technologies and improved processing methods are enhancing the quality and performance of RCA, making it more comparable to traditional natural aggregates in concrete production. Future trends indicate a significant rise in the use of RCA driven by circular economy principles and urban mining initiatives, promoting reduced landfill waste and lower carbon footprints in construction projects.

Recycled Concrete Aggregate vs Natural Aggregate Infographic

materialdif.com

materialdif.com