Polished concrete offers a sleek, natural finish that is highly durable and low-maintenance, making it ideal for both commercial and residential spaces. Epoxy coated concrete provides a glossy, protective layer that enhances resistance to chemicals, stains, and moisture, perfect for industrial or high-traffic areas. Both options improve concrete's longevity and aesthetics but differ in application, appearance, and maintenance requirements.

Table of Comparison

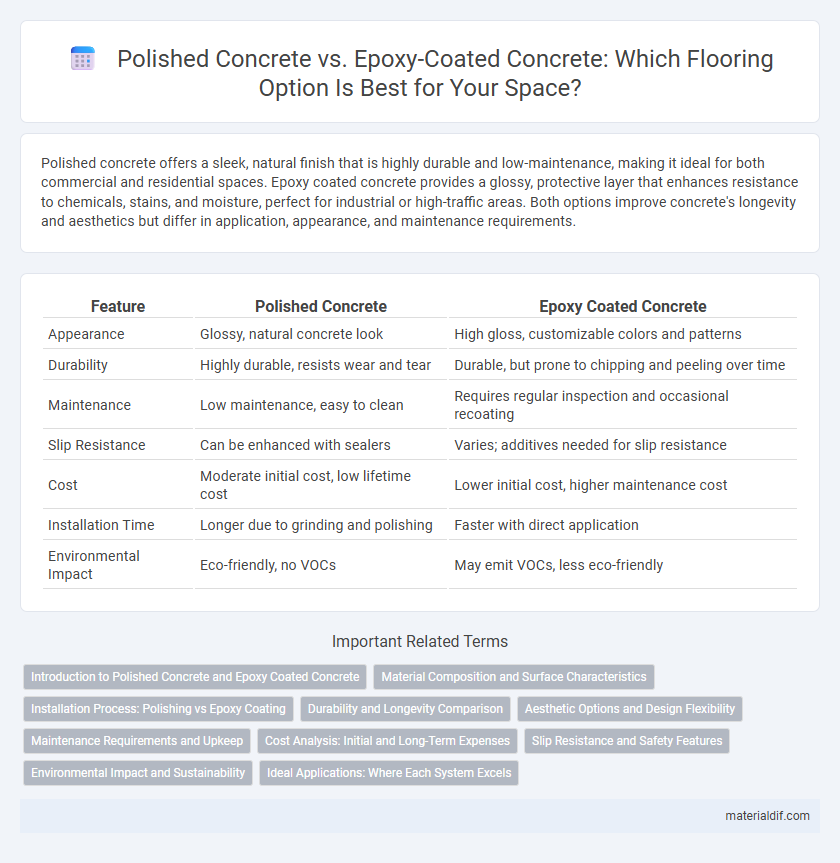

| Feature | Polished Concrete | Epoxy Coated Concrete |

|---|---|---|

| Appearance | Glossy, natural concrete look | High gloss, customizable colors and patterns |

| Durability | Highly durable, resists wear and tear | Durable, but prone to chipping and peeling over time |

| Maintenance | Low maintenance, easy to clean | Requires regular inspection and occasional recoating |

| Slip Resistance | Can be enhanced with sealers | Varies; additives needed for slip resistance |

| Cost | Moderate initial cost, low lifetime cost | Lower initial cost, higher maintenance cost |

| Installation Time | Longer due to grinding and polishing | Faster with direct application |

| Environmental Impact | Eco-friendly, no VOCs | May emit VOCs, less eco-friendly |

Introduction to Polished Concrete and Epoxy Coated Concrete

Polished concrete is a durable flooring solution achieved by mechanically grinding and polishing concrete surfaces to a high-gloss finish that enhances strength and aesthetic appeal. Epoxy coated concrete involves applying a resin-based coating that creates a seamless, protective layer resistant to chemicals, abrasions, and stains. Both options improve concrete performance but differ in maintenance requirements, longevity, and visual characteristics, making the choice dependent on specific use cases and environmental factors.

Material Composition and Surface Characteristics

Polished concrete features a hardened surface achieved by grinding and sealing the existing concrete, enhancing its natural aggregate patterns and providing a glossy finish resistant to wear and stains. Epoxy coated concrete involves applying a multi-layer epoxy resin, creating a thick, durable, and impermeable surface that resists chemical spills, impact, and abrasion. While polished concrete emphasizes the material's inherent textures and breathability, epoxy coatings offer a uniform, customizable color and higher protection against moisture ingress and surface damage.

Installation Process: Polishing vs Epoxy Coating

Polished concrete installation involves a multi-step grinding and honing process using progressively finer diamond abrasives to achieve a smooth, reflective surface without additional coatings. Epoxy coated concrete requires surface preparation, including cleaning and etching, followed by the application of primer and multiple epoxy resin layers that cure to form a durable, protective finish. Polishing is a mechanical process that enhances the concrete's natural appearance, while epoxy coating adds a colored, glossy layer that provides chemical resistance and impact protection.

Durability and Longevity Comparison

Polished concrete offers exceptional durability due to its densely compacted surface, resisting abrasion, stains, and heavy foot traffic for decades with minimal maintenance. Epoxy coated concrete provides a protective layer that enhances chemical resistance and surface hardness but may be prone to chipping or peeling over time, especially in high-impact environments. Overall, polished concrete typically outlasts epoxy coatings in longevity, maintaining structural integrity and appearance with less frequent repairs.

Aesthetic Options and Design Flexibility

Polished concrete offers a sleek, glossy finish that enhances the natural texture and color variations of the concrete, providing a modern, high-end look with options like exposed aggregate or stained patterns. Epoxy coated concrete allows for a broader range of custom designs, colors, and textures, including metallic effects and decorative chips, making it ideal for creative and personalized aesthetics. Both surfaces offer durable finishes, but epoxy's versatility in design options outpaces polished concrete for more dynamic and customizable spaces.

Maintenance Requirements and Upkeep

Polished concrete requires minimal maintenance, involving regular dust mopping and occasional damp mopping to retain its glossy finish and prevent surface scratches. Epoxy coated concrete demands more frequent upkeep, including periodic inspections to address potential peeling, chipping, or discoloration, and may require reapplication every few years to maintain its protective layer. Both surfaces benefit from prompt cleaning of spills, but polished concrete generally offers a more durable and low-cost solution for long-term maintenance.

Cost Analysis: Initial and Long-Term Expenses

Polished concrete generally has a higher initial cost due to labor-intensive grinding and polishing processes but offers lower long-term maintenance expenses because of its durability and resistance to wear. Epoxy coated concrete typically features a lower upfront cost with easier application; however, it may require more frequent repairs and recoating, increasing long-term expenses. Evaluating the total cost of ownership for both options reveals polished concrete as a more cost-effective solution in high-traffic or industrial environments over time.

Slip Resistance and Safety Features

Polished concrete offers moderate slip resistance with a smooth, glossy finish that can become slippery when wet, requiring additional treatments for enhanced safety. Epoxy coated concrete provides superior slip resistance through textured, non-slip additives integrated into the coating, making it ideal for high-traffic and industrial areas. Safety features in epoxy coatings include chemical resistance and impact durability, reducing the risk of accidents in hazardous environments compared to polished concrete surfaces.

Environmental Impact and Sustainability

Polished concrete offers a sustainable flooring option by utilizing the existing slab, reducing material waste and lowering the carbon footprint compared to epoxy coatings, which involve synthetic resins derived from petroleum products. Epoxy coatings, although durable and chemical-resistant, contribute to environmental concerns through volatile organic compound (VOC) emissions during application and the production process. Choosing polished concrete supports eco-friendly building practices by minimizing harmful chemicals and extending the lifecycle of the concrete substrate without additional resource consumption.

Ideal Applications: Where Each System Excels

Polished concrete excels in high-traffic commercial spaces such as retail stores and warehouses, offering durability, low maintenance, and a sleek, reflective finish that enhances natural lighting. Epoxy-coated concrete is ideal for industrial environments, garages, and healthcare facilities because of its chemical resistance, impact toughness, and ability to create a seamless, waterproof surface. Both systems improve concrete longevity but are chosen based on specific functional needs and aesthetic preferences.

Polished Concrete vs Epoxy Coated Concrete Infographic

materialdif.com

materialdif.com