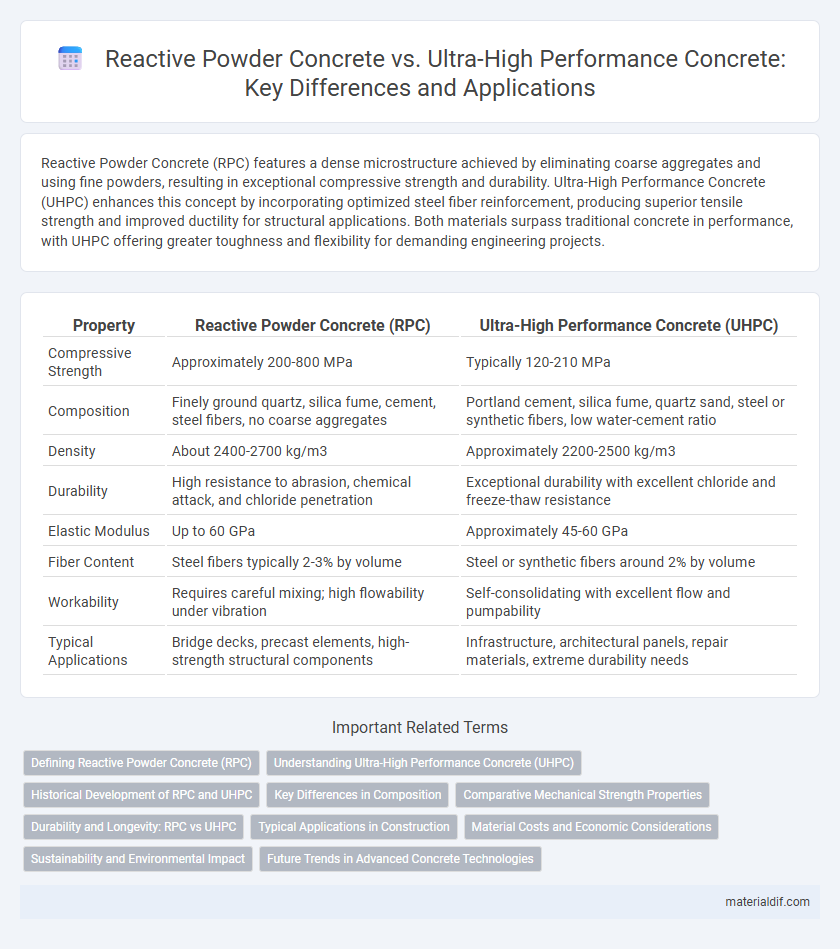

Reactive Powder Concrete (RPC) features a dense microstructure achieved by eliminating coarse aggregates and using fine powders, resulting in exceptional compressive strength and durability. Ultra-High Performance Concrete (UHPC) enhances this concept by incorporating optimized steel fiber reinforcement, producing superior tensile strength and improved ductility for structural applications. Both materials surpass traditional concrete in performance, with UHPC offering greater toughness and flexibility for demanding engineering projects.

Table of Comparison

| Property | Reactive Powder Concrete (RPC) | Ultra-High Performance Concrete (UHPC) |

|---|---|---|

| Compressive Strength | Approximately 200-800 MPa | Typically 120-210 MPa |

| Composition | Finely ground quartz, silica fume, cement, steel fibers, no coarse aggregates | Portland cement, silica fume, quartz sand, steel or synthetic fibers, low water-cement ratio |

| Density | About 2400-2700 kg/m3 | Approximately 2200-2500 kg/m3 |

| Durability | High resistance to abrasion, chemical attack, and chloride penetration | Exceptional durability with excellent chloride and freeze-thaw resistance |

| Elastic Modulus | Up to 60 GPa | Approximately 45-60 GPa |

| Fiber Content | Steel fibers typically 2-3% by volume | Steel or synthetic fibers around 2% by volume |

| Workability | Requires careful mixing; high flowability under vibration | Self-consolidating with excellent flow and pumpability |

| Typical Applications | Bridge decks, precast elements, high-strength structural components | Infrastructure, architectural panels, repair materials, extreme durability needs |

Defining Reactive Powder Concrete (RPC)

Reactive Powder Concrete (RPC) is an advanced type of high-performance concrete characterized by its ultra-fine powders and optimized particle packing, resulting in exceptional strength and durability. RPC typically incorporates a mix of silica fume, quartz powder, fine sand, cement, and steel fibers, combined using very low water-cement ratios to achieve near-zero porosity and enhanced mechanical properties. This material's refined microstructure and reactive components differentiate it from standard concretes, providing superior compressive strength often exceeding 200 MPa.

Understanding Ultra-High Performance Concrete (UHPC)

Ultra-High Performance Concrete (UHPC) is a cementitious composite characterized by superior strength, durability, and enhanced microstructure compared to Reactive Powder Concrete (RPC). UHPC typically achieves compressive strengths exceeding 150 MPa due to optimized particle packing, high cementitious content, and the inclusion of steel fibers that improve tensile performance and fracture toughness. Its advanced properties result from refined mix designs, low water-to-cement ratios, and intensive grinding processes, making UHPC ideal for critical infrastructure and architectural applications requiring exceptional load-bearing capacity and resilience.

Historical Development of RPC and UHPC

Reactive Powder Concrete (RPC) was developed in the 1990s by the French scientific research institute, LCPC, focusing on replacing coarse aggregates with fine powders to achieve enhanced strength and durability. Ultra-High Performance Concrete (UHPC) evolved from the innovations in RPC, integrating optimized particle packing and fiber reinforcement to push strength beyond 150 MPa while improving ductility and toughness. Both materials represent significant advancements in concrete technology, with RPC marking the transition to finer particle matrices and UHPC establishing superior mechanical and durability characteristics for high-performance structural applications.

Key Differences in Composition

Reactive Powder Concrete (RPC) incorporates fine powders like silica fume, quartz, and cement with very low water content, resulting in a dense microstructure due to reduced porosity. Ultra-High Performance Concrete (UHPC) includes similar fine materials but uses steel fibers and higher cement content to enhance tensile strength and ductility. The key compositional difference lies in RPC's emphasis on powder optimization and particle packing, whereas UHPC relies on fiber reinforcement and advanced admixtures to achieve superior mechanical properties.

Comparative Mechanical Strength Properties

Reactive Powder Concrete (RPC) demonstrates compressive strengths typically ranging from 150 to 200 MPa, while Ultra-High Performance Concrete (UHPC) often exceeds 200 MPa, reaching up to 250 MPa. Both materials exhibit superior tensile strength and ductility compared to conventional concrete, but UHPC generally offers enhanced mechanical performance due to optimized fiber content and matrix densification. The improved mechanical properties of UHPC contribute to greater durability and load-bearing capacity in structural applications.

Durability and Longevity: RPC vs UHPC

Reactive Powder Concrete (RPC) and Ultra-High Performance Concrete (UHPC) both offer exceptional durability, with UHPC typically exhibiting higher compressive strengths above 150 MPa and superior resistance to chemical attacks and freeze-thaw cycles. RPC demonstrates enhanced durability due to its refined microstructure achieved through the absence of coarse aggregates, which reduces permeability and increases resistance to abrasion and shrinkage. The longevity of UHPC surpasses traditional concretes, making it ideal for infrastructure exposed to harsh environments, while RPC provides a cost-effective solution with notable durability for pavement and structural repairs.

Typical Applications in Construction

Reactive Powder Concrete (RPC) is typically used in bridge components, precast panels, and industrial flooring due to its enhanced durability and high compressive strength. Ultra-High Performance Concrete (UHPC) finds application in architectural cladding, security barriers, and complex structural elements requiring exceptional tensile strength and toughness. Both materials are favored for infrastructure projects demanding superior performance and long service life.

Material Costs and Economic Considerations

Reactive Powder Concrete (RPC) generally has higher material costs compared to Ultra-High Performance Concrete (UHPC) due to its use of fine powders like silica fume and quartz, which enhance durability but increase expenses. UHPC incorporates optimized particle packing and fiber reinforcement, offering superior mechanical properties and longer service life that can offset its initial investment through reduced maintenance costs. Economic considerations favor UHPC in large-scale or critical infrastructure projects where performance and longevity justify the premium material cost.

Sustainability and Environmental Impact

Reactive Powder Concrete (RPC) and Ultra-High Performance Concrete (UHPC) both offer advanced material properties but differ in sustainability and environmental impact. RPC typically uses finer materials and higher cement content, resulting in increased carbon emissions compared to UHPC, which often incorporates supplementary cementitious materials like silica fume and fly ash to reduce its carbon footprint. UHPC's enhanced durability and longer lifespan contribute to lower life-cycle environmental impacts, making it a more sustainable choice for eco-conscious construction projects.

Future Trends in Advanced Concrete Technologies

Future trends in advanced concrete technologies highlight increased integration of nanotechnology and fiber optimization in Reactive Powder Concrete (RPC) and Ultra-High Performance Concrete (UHPC) to enhance mechanical properties and durability. Sustainable manufacturing processes, including the use of recycled materials and low-carbon binders, are expected to drive widespread adoption of these high-performance concretes. Digital tools such as machine learning for mix design optimization and real-time structural health monitoring are transforming the development and application of RPC and UHPC in infrastructure projects.

Reactive Powder Concrete vs Ultra-High Performance Concrete Infographic

materialdif.com

materialdif.com