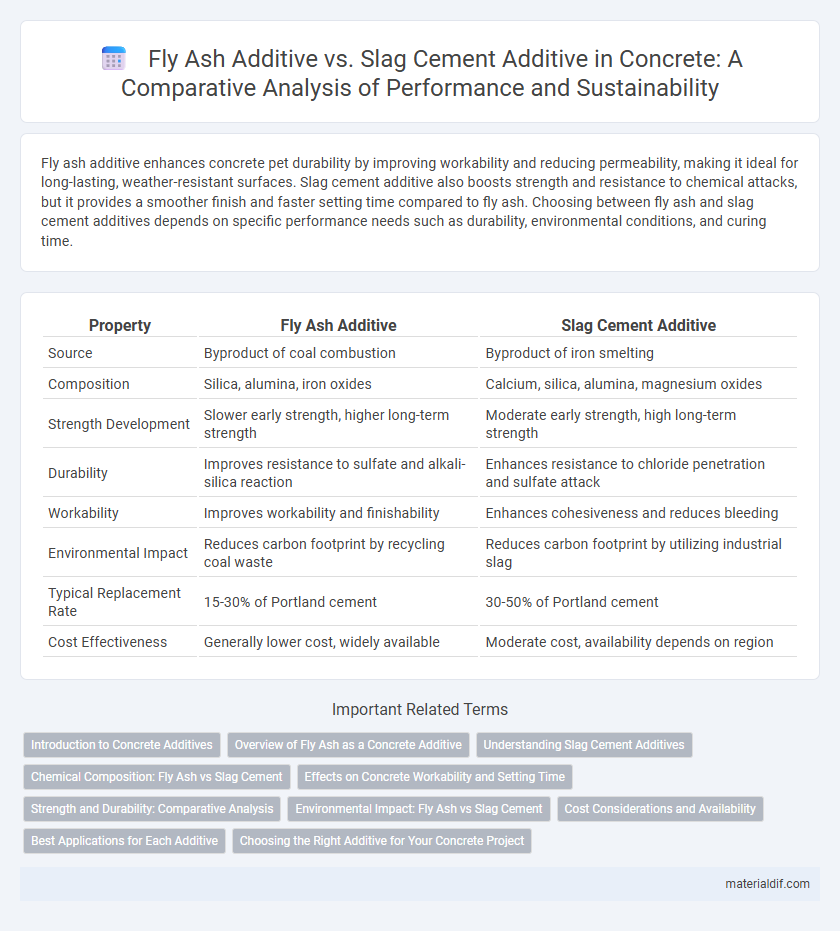

Fly ash additive enhances concrete pet durability by improving workability and reducing permeability, making it ideal for long-lasting, weather-resistant surfaces. Slag cement additive also boosts strength and resistance to chemical attacks, but it provides a smoother finish and faster setting time compared to fly ash. Choosing between fly ash and slag cement additives depends on specific performance needs such as durability, environmental conditions, and curing time.

Table of Comparison

| Property | Fly Ash Additive | Slag Cement Additive |

|---|---|---|

| Source | Byproduct of coal combustion | Byproduct of iron smelting |

| Composition | Silica, alumina, iron oxides | Calcium, silica, alumina, magnesium oxides |

| Strength Development | Slower early strength, higher long-term strength | Moderate early strength, high long-term strength |

| Durability | Improves resistance to sulfate and alkali-silica reaction | Enhances resistance to chloride penetration and sulfate attack |

| Workability | Improves workability and finishability | Enhances cohesiveness and reduces bleeding |

| Environmental Impact | Reduces carbon footprint by recycling coal waste | Reduces carbon footprint by utilizing industrial slag |

| Typical Replacement Rate | 15-30% of Portland cement | 30-50% of Portland cement |

| Cost Effectiveness | Generally lower cost, widely available | Moderate cost, availability depends on region |

Introduction to Concrete Additives

Fly ash additive enhances concrete strength and durability by improving workability and reducing permeability through its pozzolanic properties. Slag cement additive contributes to concrete's resistance to chemical attack and sulfate corrosion, while also promoting a denser microstructure. Both additives optimize concrete performance by substituting a portion of Portland cement, reducing environmental impact and enhancing long-term durability.

Overview of Fly Ash as a Concrete Additive

Fly ash, a byproduct of coal combustion in power plants, serves as a supplementary cementitious material in concrete, enhancing durability and reducing permeability. Its fine particles improve workability and contribute to the pozzolanic reaction, which increases long-term strength by reacting with calcium hydroxide. Compared to slag cement, fly ash offers cost efficiency and environmental benefits by recycling industrial waste and lowering the carbon footprint of concrete production.

Understanding Slag Cement Additives

Slag cement additives, derived from ground granulated blast-furnace slag, enhance concrete durability by improving resistance to sulfate attacks and reducing permeability. These additives promote a denser microstructure and contribute to lower heat of hydration compared to fly ash additives, which are byproducts of coal combustion. Understanding slag cement's chemical composition and pozzolanic properties is crucial for optimizing concrete performance in aggressive environments.

Chemical Composition: Fly Ash vs Slag Cement

Fly ash primarily consists of silicon dioxide (SiO2), aluminum oxide (Al2O3), and iron oxide (Fe2O3), contributing to its pozzolanic properties that enhance concrete strength and durability. In contrast, slag cement contains higher amounts of calcium oxide (CaO), along with magnesium oxide (MgO) and alumina, which promotes hydraulic cementitious reactions improving workability and sulfate resistance. The differing chemical compositions determine each additive's influence on hydration kinetics and long-term concrete performance.

Effects on Concrete Workability and Setting Time

Fly ash additive improves concrete workability by enhancing flowability due to its spherical particle shape, which reduces water demand and aids in achieving a smooth mix. Slag cement additive also improves workability but often results in a slower initial set time compared to fly ash, providing extended workability periods ideal for large pours. Both additives contribute to a prolonged setting time compared to ordinary Portland cement, with slag cement typically causing a more noticeable delay in the setting process.

Strength and Durability: Comparative Analysis

Fly ash additives improve concrete strength through enhanced pozzolanic reactions, resulting in denser microstructures and increased long-term durability by reducing permeability and mitigating alkali-silica reaction risks. Slag cement additives contribute to high early strength development and superior sulfate resistance, enhancing durability in aggressive environments. Comparative studies indicate fly ash excels in long-term strength gains, while slag cement provides faster strength attainment and improved resistance against chemical attacks.

Environmental Impact: Fly Ash vs Slag Cement

Fly ash additive significantly reduces the carbon footprint of concrete by recycling industrial waste from coal combustion, lowering greenhouse gas emissions compared to traditional cement. Slag cement, derived from blast furnace slag, also offers environmental benefits by minimizing landfill waste and reducing energy consumption during production. Both additives improve sustainability, but fly ash generally has a greater impact due to its higher availability and larger reduction in CO2 emissions per ton.

Cost Considerations and Availability

Fly ash additive is generally more cost-effective than slag cement due to its widespread availability as a byproduct of coal combustion, resulting in lower procurement expenses. Slag cement, derived from blast furnace slag, tends to have higher costs influenced by regional production capacity and transportation logistics. Both additives' availability varies geographically, with fly ash commonly accessible in coal-producing areas, while slag cement is more prevalent near steel manufacturing hubs.

Best Applications for Each Additive

Fly ash additive is best suited for large-scale concrete projects requiring enhanced workability, reduced heat of hydration, and improved long-term strength, making it ideal for mass concrete, pavements, and structural beams. Slag cement additive excels in applications demanding high durability, sulfate resistance, and rapid strength gain, such as marine structures, sewage treatment plants, and precast concrete units. Selecting the appropriate additive depends on project-specific factors like exposure conditions, desired strength development, and environmental considerations.

Choosing the Right Additive for Your Concrete Project

Fly ash additive enhances concrete durability and workability by improving sulfate resistance and reducing permeability, making it ideal for large-scale infrastructure projects. Slag cement additive provides superior strength development and corrosion resistance, suited for marine or industrial environments requiring high early strength. Selecting between fly ash and slag cement depends on specific project demands such as exposure conditions, setting time requirements, and long-term performance goals.

Fly Ash Additive vs Slag Cement Additive Infographic

materialdif.com

materialdif.com