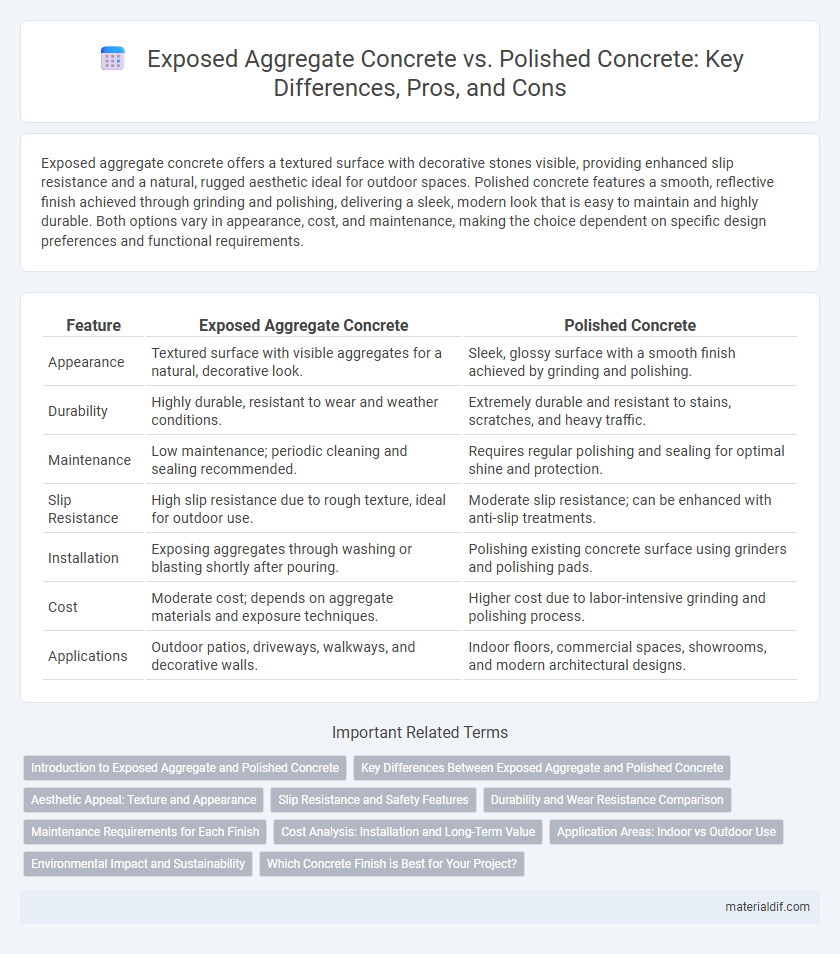

Exposed aggregate concrete offers a textured surface with decorative stones visible, providing enhanced slip resistance and a natural, rugged aesthetic ideal for outdoor spaces. Polished concrete features a smooth, reflective finish achieved through grinding and polishing, delivering a sleek, modern look that is easy to maintain and highly durable. Both options vary in appearance, cost, and maintenance, making the choice dependent on specific design preferences and functional requirements.

Table of Comparison

| Feature | Exposed Aggregate Concrete | Polished Concrete |

|---|---|---|

| Appearance | Textured surface with visible aggregates for a natural, decorative look. | Sleek, glossy surface with a smooth finish achieved by grinding and polishing. |

| Durability | Highly durable, resistant to wear and weather conditions. | Extremely durable and resistant to stains, scratches, and heavy traffic. |

| Maintenance | Low maintenance; periodic cleaning and sealing recommended. | Requires regular polishing and sealing for optimal shine and protection. |

| Slip Resistance | High slip resistance due to rough texture, ideal for outdoor use. | Moderate slip resistance; can be enhanced with anti-slip treatments. |

| Installation | Exposing aggregates through washing or blasting shortly after pouring. | Polishing existing concrete surface using grinders and polishing pads. |

| Cost | Moderate cost; depends on aggregate materials and exposure techniques. | Higher cost due to labor-intensive grinding and polishing process. |

| Applications | Outdoor patios, driveways, walkways, and decorative walls. | Indoor floors, commercial spaces, showrooms, and modern architectural designs. |

Introduction to Exposed Aggregate and Polished Concrete

Exposed aggregate concrete features a textured surface achieved by removing the top layer of cement paste to reveal embedded decorative stones, providing enhanced durability and slip resistance ideal for driveways and walkways. Polished concrete undergoes a mechanical grinding process to create a smooth, shiny finish that highlights the concrete's natural patterns while offering low maintenance and increased strength. Both methods enhance aesthetic appeal and functionality but differ in surface texture and application suitability, catering to various architectural and landscaping needs.

Key Differences Between Exposed Aggregate and Polished Concrete

Exposed aggregate concrete features a textured surface with visible stones for slip resistance and decorative appeal, while polished concrete offers a smooth, reflective finish achieved through grinding and sealing processes. Exposed aggregate provides enhanced durability and traction ideal for outdoor applications, whereas polished concrete is favored indoors for its sleek appearance and ease of maintenance. Both types differ significantly in surface treatment, aesthetic value, and suitability for varying environments and design preferences.

Aesthetic Appeal: Texture and Appearance

Exposed aggregate concrete showcases a distinctive, textured surface created by revealing the natural stone beneath the cement, offering a rugged, decorative appearance ideal for outdoor spaces. Polished concrete features a smooth, glossy finish achieved through mechanical grinding and polishing processes, enhancing the concrete's natural color and patterns for a sleek, modern look. The choice between exposed aggregate and polished concrete depends on desired aesthetic appeal, with exposed aggregate highlighting texture and earthy tones while polished concrete emphasizes shine and uniformity.

Slip Resistance and Safety Features

Exposed aggregate concrete offers superior slip resistance due to its textured surface, making it ideal for outdoor walkways and pool decks where safety is paramount. Polished concrete, while visually appealing and smooth, generally requires additional treatments or coatings to enhance traction and prevent slips in wet or high-traffic areas. Selecting the appropriate finish depends on balancing aesthetic preferences with the need for slip resistance and overall safety requirements.

Durability and Wear Resistance Comparison

Exposed aggregate concrete offers superior durability due to its rough surface texture, which enhances resistance to wear and skid, making it ideal for high-traffic outdoor areas. Polished concrete surfaces, while aesthetically smooth and reflective, rely heavily on sealants, which can wear down over time and require periodic maintenance to preserve their wear resistance. When comparing longevity, exposed aggregate concrete typically outperforms polished concrete in abrasive environments, ensuring extended structural integrity under heavy use.

Maintenance Requirements for Each Finish

Exposed aggregate concrete requires periodic sealing and concrete cleaning to prevent surface damage and maintain its textured appearance, making it moderately maintenance-intensive. Polished concrete demands regular dust mopping and occasional damp mopping with pH-neutral cleaners to preserve its glossy finish and prevent surface abrasion, offering relatively low maintenance. Both finishes benefit from timely stain removal, but polished concrete generally requires less frequent sealing compared to exposed aggregate surfaces.

Cost Analysis: Installation and Long-Term Value

Exposed aggregate concrete generally costs less to install than polished concrete due to its simpler finishing process and reduced labor requirements. Polished concrete involves grinding and sealing steps, increasing upfront expenses but offering enhanced durability and minimal maintenance over time. Long-term value favors polished concrete as its resistance to wear and ability to retain a high-gloss finish contribute to lower repair costs and increased lifespan.

Application Areas: Indoor vs Outdoor Use

Exposed aggregate concrete is ideal for outdoor applications such as driveways, patios, and walkways due to its slip-resistant texture and durability against weather elements. Polished concrete is predominantly used indoors in commercial spaces, retail stores, and modern residential interiors, offering a smooth, reflective surface with enhanced aesthetic appeal. Both finishes provide distinct functional advantages tailored to either exterior roughness or interior sleekness based on specific environmental needs.

Environmental Impact and Sustainability

Exposed aggregate concrete offers enhanced durability with minimal maintenance, reducing the need for frequent repairs and lowering long-term environmental impact through decreased resource consumption. Polished concrete, achieved by mechanically grinding and sealing the surface, eliminates the need for additional floor coverings, reducing waste and enhancing indoor air quality by minimizing dust and allergens. Both options contribute to sustainable construction practices by utilizing existing materials and promoting longevity, but polished concrete tends to have a lower carbon footprint during its lifecycle due to reduced chemical treatments and maintenance requirements.

Which Concrete Finish is Best for Your Project?

Exposed aggregate concrete offers a textured, slip-resistant surface ideal for outdoor walkways and driveways, enhancing durability and aesthetic appeal with natural stone accents. Polished concrete provides a sleek, glossy finish suitable for indoor commercial and residential spaces, offering low maintenance and high reflectivity for improved lighting. Choosing between exposed aggregate and polished concrete depends on project requirements like location, desired texture, maintenance, and visual impact.

Exposed Aggregate Concrete vs Polished Concrete Infographic

materialdif.com

materialdif.com