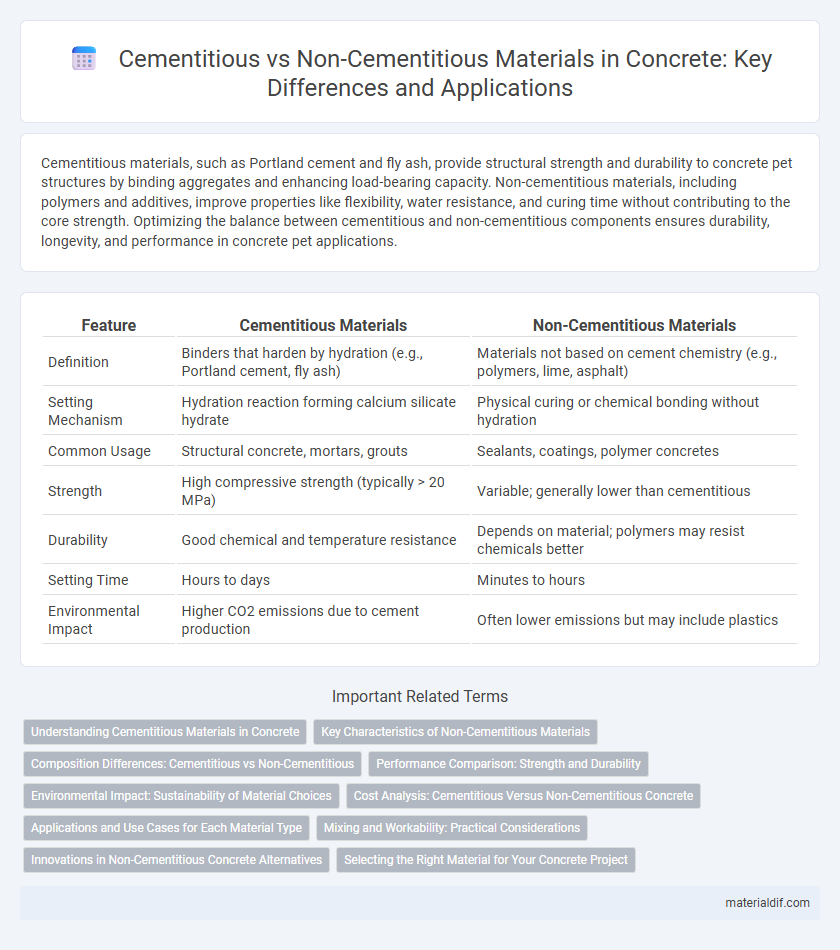

Cementitious materials, such as Portland cement and fly ash, provide structural strength and durability to concrete pet structures by binding aggregates and enhancing load-bearing capacity. Non-cementitious materials, including polymers and additives, improve properties like flexibility, water resistance, and curing time without contributing to the core strength. Optimizing the balance between cementitious and non-cementitious components ensures durability, longevity, and performance in concrete pet applications.

Table of Comparison

| Feature | Cementitious Materials | Non-Cementitious Materials |

|---|---|---|

| Definition | Binders that harden by hydration (e.g., Portland cement, fly ash) | Materials not based on cement chemistry (e.g., polymers, lime, asphalt) |

| Setting Mechanism | Hydration reaction forming calcium silicate hydrate | Physical curing or chemical bonding without hydration |

| Common Usage | Structural concrete, mortars, grouts | Sealants, coatings, polymer concretes |

| Strength | High compressive strength (typically > 20 MPa) | Variable; generally lower than cementitious |

| Durability | Good chemical and temperature resistance | Depends on material; polymers may resist chemicals better |

| Setting Time | Hours to days | Minutes to hours |

| Environmental Impact | Higher CO2 emissions due to cement production | Often lower emissions but may include plastics |

Understanding Cementitious Materials in Concrete

Cementitious materials in concrete, such as Portland cement, fly ash, and slag, chemically react with water to form a hardened matrix that binds aggregates, providing strength and durability. Unlike non-cementitious materials, which do not contribute to the cement hydration process, cementitious components are essential for the concrete's structural integrity and long-term performance. Optimizing the proportion of cementitious materials enhances concrete's compressive strength, setting time, and resistance to environmental factors.

Key Characteristics of Non-Cementitious Materials

Non-cementitious materials lack the binding properties of cementitious counterparts, relying on physical adhesion or mechanical interlocking for strength. Key characteristics include resistance to chemical attacks, enhanced flexibility, and lower shrinkage, making them suitable for specialized construction applications. Examples include polymers, bituminous materials, and certain aggregates that improve durability and water resistance without hydraulic setting.

Composition Differences: Cementitious vs Non-Cementitious

Cementitious materials primarily consist of hydraulic compounds such as Portland cement, fly ash, slag, and silica fume, which undergo chemical hydration to form hardened binding phases. Non-cementitious materials, on the other hand, lack these hydraulic components and are often composed of polymers, lime, or natural pozzolans that rely on different chemical or physical mechanisms for cohesion. The distinct chemical compositions between cementitious and non-cementitious materials drastically influence their setting behavior, strength development, and durability characteristics in concrete applications.

Performance Comparison: Strength and Durability

Cementitious materials, such as Portland cement, generally exhibit superior compressive strength and durability compared to non-cementitious materials like lime or gypsum-based binders. The hydraulic properties and pozzolanic reactions in cementitious materials enhance microstructural density, resulting in higher resistance to chemical attack, freeze-thaw cycles, and abrasion. In contrast, non-cementitious materials often have lower early strength development and reduced long-term durability under aggressive environmental conditions.

Environmental Impact: Sustainability of Material Choices

Cementitious materials, such as Portland cement, are major contributors to global CO2 emissions, accounting for approximately 8% of anthropogenic carbon dioxide, raising concerns about their environmental impact and sustainability. Non-cementitious materials like geopolymers and lime-based binders offer reduced carbon footprints by utilizing industrial byproducts and natural minerals, enhancing eco-friendly construction practices. Selecting sustainable material choices in concrete production significantly reduces resource depletion and greenhouse gas emissions, supporting global efforts to mitigate climate change.

Cost Analysis: Cementitious Versus Non-Cementitious Concrete

Cementitious materials typically incur higher initial costs due to cement production and processing but offer long-term durability and strength benefits that reduce maintenance expenses. Non-cementitious alternatives such as geopolymers or polymer concretes often lower environmental impact and energy use but may require specialized additives or curing processes, impacting overall cost. Cost analysis must consider lifecycle costs, including raw material availability, installation complexity, and performance requirements in specific construction applications.

Applications and Use Cases for Each Material Type

Cementitious materials, such as Portland cement and supplementary cementitious materials like fly ash and silica fume, are widely used in structural concrete for buildings, bridges, and infrastructure due to their high compressive strength and durability. Non-cementitious materials, including lime, clay, and geopolymers, find applications in restoration projects, environmental construction, and sustainable building solutions where lower carbon footprint or specific chemical resistance is required. Each material type is selected based on project demands for mechanical properties, environmental impact, and long-term performance in diverse construction scenarios.

Mixing and Workability: Practical Considerations

Cementitious materials, such as Portland cement, enhance mixing uniformity and improve workability by providing a cohesive paste that facilitates particle bonding and flow. Non-cementitious materials like fly ash and slag often serve as supplementary binders, influencing slump retention and water demand during mixing. Practical considerations include adjusting water-cement ratios and admixture types to optimize consistency, setting times, and ease of placement in concrete applications.

Innovations in Non-Cementitious Concrete Alternatives

Innovations in non-cementitious concrete alternatives focus on sustainable binders such as geopolymers, alkali-activated materials, and magnesium-based cements, which significantly reduce carbon emissions compared to traditional Portland cement. Advanced formulations using industrial byproducts like fly ash, slag, and silica fume enhance durability, strength, and chemical resistance without relying on cement. Research into bio-based binders and novel nanomaterials further drives improved performance and eco-efficiency in non-cementitious construction composites.

Selecting the Right Material for Your Concrete Project

Selecting the right material for your concrete project hinges on understanding the differences between cementitious and non-cementitious materials, where cementitious materials such as Portland cement, fly ash, and slag provide essential binding properties and strength development. Non-cementitious materials, including aggregates, fibers, and chemical admixtures, enhance durability, workability, and specific performance traits like crack resistance and curing acceleration. Optimizing the blend of these materials based on project requirements ensures structural integrity, longevity, and cost-efficiency in concrete construction.

Cementitious materials vs non-cementitious materials Infographic

materialdif.com

materialdif.com