Ultra-High Performance Concrete (UHPC) outperforms standard concrete with significantly higher compressive strength, enhanced durability, and superior resistance to environmental degradation. UHPC incorporates fine powders, fibers, and optimized mix designs, resulting in a denser microstructure and improved tensile properties compared to traditional concrete. This advanced material is ideal for demanding infrastructure projects requiring extended service life and reduced maintenance costs.

Table of Comparison

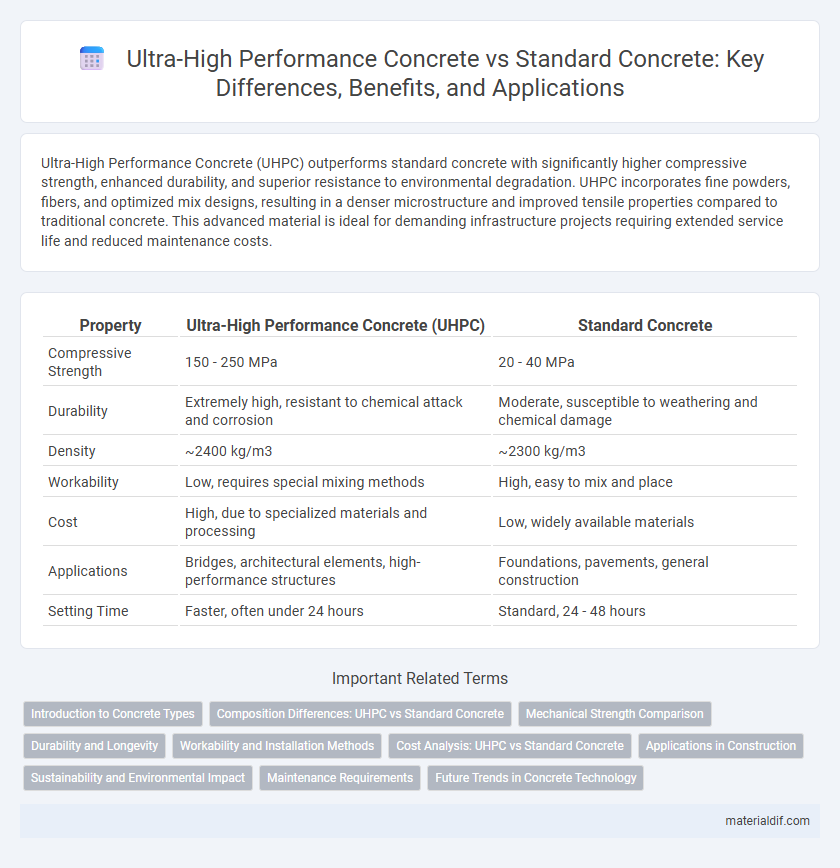

| Property | Ultra-High Performance Concrete (UHPC) | Standard Concrete |

|---|---|---|

| Compressive Strength | 150 - 250 MPa | 20 - 40 MPa |

| Durability | Extremely high, resistant to chemical attack and corrosion | Moderate, susceptible to weathering and chemical damage |

| Density | ~2400 kg/m3 | ~2300 kg/m3 |

| Workability | Low, requires special mixing methods | High, easy to mix and place |

| Cost | High, due to specialized materials and processing | Low, widely available materials |

| Applications | Bridges, architectural elements, high-performance structures | Foundations, pavements, general construction |

| Setting Time | Faster, often under 24 hours | Standard, 24 - 48 hours |

Introduction to Concrete Types

Ultra-High Performance Concrete (UHPC) distinguishes itself from Standard Concrete by its exceptional compressive strength exceeding 150 MPa, compared to the typical 20-40 MPa range of standard mixes. UHPC incorporates fine powders, steel fibers, and optimized particle packing, resulting in enhanced durability, reduced permeability, and superior mechanical properties. Standard Concrete, primarily composed of cement, water, sand, and coarse aggregates, serves as a versatile, cost-effective material widely used in construction but lacks the specialized performance characteristics of UHPC.

Composition Differences: UHPC vs Standard Concrete

Ultra-High Performance Concrete (UHPC) distinguishes itself from standard concrete through a superior composition featuring fine powders such as silica fume, quartz sand, and a high cementitious content, resulting in a denser microstructure. The inclusion of steel fibers in UHPC enhances tensile strength and toughness, unlike conventional concrete which relies heavily on coarse aggregates and has limited fiber reinforcement. Low water-to-cement ratios and optimized particle packing in UHPC significantly improve durability and mechanical properties compared to standard concrete mixes.

Mechanical Strength Comparison

Ultra-High Performance Concrete (UHPC) exhibits compressive strengths typically exceeding 150 MPa, outperforming standard concrete which generally ranges between 20 to 40 MPa. The tensile strength of UHPC can reach up to 10-15 MPa due to its dense microstructure and fiber reinforcement, in contrast to standard concrete's tensile strength of approximately 2-5 MPa. This significant mechanical strength enhancement makes UHPC highly suitable for applications requiring superior durability and load-bearing capacity.

Durability and Longevity

Ultra-High Performance Concrete (UHPC) exhibits significantly greater durability compared to standard concrete due to its dense microstructure, which resists cracking, chemical attack, and abrasion more effectively. UHPC's advanced composition, including fine powders and fiber reinforcement, enhances its longevity by minimizing permeability and increasing resistance to freeze-thaw cycles. Standard concrete typically requires more frequent maintenance and repairs as it is more susceptible to environmental degradation and mechanical wear.

Workability and Installation Methods

Ultra-High Performance Concrete (UHPC) offers superior workability through its fine particle size and optimized mix design, enabling easier flow into complex molds and tighter reinforcement configurations compared to Standard Concrete. UHPC requires specialized installation methods such as high-pressure casting or shotcrete application, whereas Standard Concrete typically uses traditional pouring and vibration techniques. These differences impact project timelines and labor skill requirements, with UHPC demanding precise placement to maximize its mechanical properties.

Cost Analysis: UHPC vs Standard Concrete

Ultra-High Performance Concrete (UHPC) typically incurs costs three to five times higher than standard concrete due to advanced materials like silica fume and steel fibers used in its composition. Despite the initial expense, UHPC offers superior durability and reduced maintenance costs over its service life, potentially offsetting upfront investments. The cost efficiency of UHPC becomes more pronounced in infrastructure projects requiring high strength and longevity, where lifecycle benefits outweigh the premium price.

Applications in Construction

Ultra-High Performance Concrete (UHPC) is utilized in applications requiring exceptional strength, durability, and resistance to environmental factors, such as bridge components, facades, and protective structures. Standard Concrete remains prevalent for general construction purposes, including foundations, slabs, and walls, where cost-effectiveness and adequate performance are priorities. UHPC's enhanced mechanical properties enable thinner, lighter structures with longer service life, making it ideal for innovative architectural designs and infrastructure exposed to harsh conditions.

Sustainability and Environmental Impact

Ultra-High Performance Concrete (UHPC) significantly reduces environmental impact by enhancing durability and lifespan, thus lowering lifecycle carbon emissions compared to Standard Concrete. Its dense microstructure minimizes permeability, leading to less maintenance and resource consumption over time. UHPC's potential for reduced material usage and improved strength also supports sustainable construction practices by decreasing the overall carbon footprint.

Maintenance Requirements

Ultra-High Performance Concrete (UHPC) requires significantly less maintenance than standard concrete due to its superior durability, enhanced resistance to cracking, and lower permeability. Standard concrete often demands more frequent repairs and surface treatments to address issues like spalling, freeze-thaw damage, and chemical deterioration. The reduced maintenance frequency of UHPC translates to lower lifecycle costs and extended structural service life in infrastructure applications.

Future Trends in Concrete Technology

Ultra-High Performance Concrete (UHPC) offers superior strength, durability, and sustainability compared to standard concrete, driving a shift toward more resilient infrastructure. Innovations in nanotechnology and fiber reinforcements are enhancing UHPC's mechanical properties and reducing its environmental footprint. Future trends emphasize integrating smart sensors within UHPC to enable real-time structural health monitoring and predictive maintenance.

Ultra-High Performance Concrete vs Standard Concrete Infographic

materialdif.com

materialdif.com