Green concrete significantly reduces carbon emissions by incorporating recycled materials and industrial by-products, making it an eco-friendly alternative to conventional concrete. Conventional concrete relies heavily on cement, a major source of CO2 emissions, whereas green concrete uses supplementary cementitious materials to lower its environmental footprint. This sustainable approach not only conserves natural resources but also enhances durability and reduces waste in construction projects.

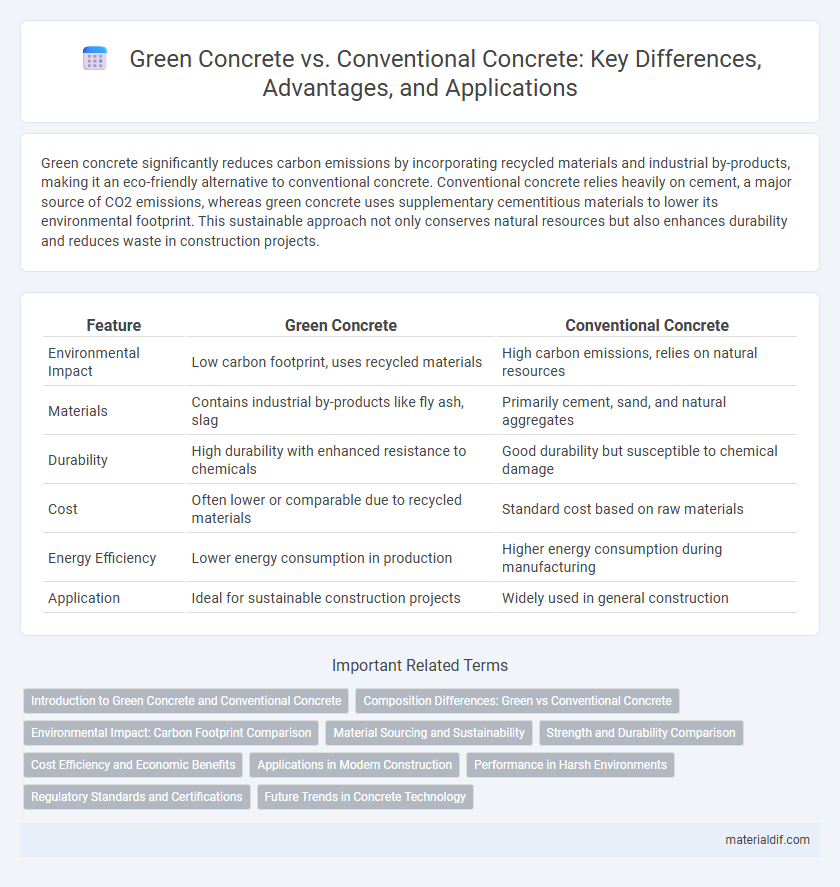

Table of Comparison

| Feature | Green Concrete | Conventional Concrete |

|---|---|---|

| Environmental Impact | Low carbon footprint, uses recycled materials | High carbon emissions, relies on natural resources |

| Materials | Contains industrial by-products like fly ash, slag | Primarily cement, sand, and natural aggregates |

| Durability | High durability with enhanced resistance to chemicals | Good durability but susceptible to chemical damage |

| Cost | Often lower or comparable due to recycled materials | Standard cost based on raw materials |

| Energy Efficiency | Lower energy consumption in production | Higher energy consumption during manufacturing |

| Application | Ideal for sustainable construction projects | Widely used in general construction |

Introduction to Green Concrete and Conventional Concrete

Green concrete utilizes industrial waste materials such as fly ash, slag, and recycled aggregates to reduce environmental impact, offering enhanced sustainability compared to conventional concrete. Conventional concrete primarily consists of cement, water, sand, and coarse aggregates, contributing significantly to carbon dioxide emissions during cement production. Green concrete's innovative composition helps lower carbon footprint and energy consumption while maintaining comparable strength and durability to traditional concrete formulations.

Composition Differences: Green vs Conventional Concrete

Green concrete incorporates industrial by-products like fly ash, slag, and recycled aggregates, reducing the demand for Portland cement and lowering carbon emissions compared to conventional concrete. Conventional concrete primarily relies on a mixture of Portland cement, water, sand, and natural aggregates, resulting in higher energy consumption and environmental impact. The use of supplementary cementitious materials in green concrete enhances sustainability without compromising strength and durability.

Environmental Impact: Carbon Footprint Comparison

Green concrete reduces the carbon footprint significantly by incorporating recycled materials such as fly ash, slag, and recycled aggregates that lower cement consumption, the primary source of CO2 emissions in conventional concrete production. Conventional concrete production accounts for approximately 8% of global CO2 emissions, while green concrete innovations can cut these emissions by up to 30-50%. Using green concrete not only minimizes greenhouse gas emissions but also promotes sustainable resource utilization, making it a crucial material for eco-friendly construction projects.

Material Sourcing and Sustainability

Green concrete utilizes industrial byproducts such as fly ash, slag, and recycled aggregates, significantly reducing the need for virgin raw materials compared to conventional concrete, which primarily relies on Portland cement and natural aggregates. The production of green concrete lowers carbon emissions by minimizing cement content, the primary source of CO2 in traditional concrete manufacturing. Sustainable sourcing of materials in green concrete enhances environmental performance by promoting waste recycling and reducing extraction of natural resources.

Strength and Durability Comparison

Green concrete, incorporating recycled materials and industrial byproducts like fly ash and slag, often achieves comparable or higher compressive strength than conventional concrete due to enhanced pozzolanic reactions. Its durability is superior, exhibiting improved resistance to chemical attacks, reduced permeability, and better sulfate resistance, which extends structural lifespan. Conventional concrete, primarily reliant on cement and aggregates, may have slightly faster initial strength gain but lacks the long-term sustainability and robustness under aggressive environmental conditions demonstrated by green concrete.

Cost Efficiency and Economic Benefits

Green concrete reduces overall project costs by utilizing industrial by-products like fly ash and slag, lowering the need for expensive Portland cement. Its enhanced durability leads to decreased maintenance and repair expenses over the structure's lifespan. Long-term economic benefits include energy savings from reduced carbon emissions and potential incentives for sustainable construction practices.

Applications in Modern Construction

Green concrete, incorporating recycled materials and industrial by-products like fly ash and slag, is increasingly used in sustainable building projects to reduce carbon emissions and enhance durability. Conventional concrete remains prevalent for infrastructure requiring high compressive strength and rapid setting, such as bridges, highways, and foundations. Modern construction favors green concrete in residential buildings, pavements, and low-impact commercial projects due to its environmental benefits and adequate mechanical properties.

Performance in Harsh Environments

Green concrete exhibits superior durability and resistance in harsh environments due to its enhanced permeability and lower carbon footprint compared to conventional concrete. Its use of supplementary cementitious materials like fly ash and slag improves resistance to sulfate attack, chloride penetration, and freeze-thaw cycles. Conventional concrete often shows higher susceptibility to cracking and corrosion when exposed to aggressive chemicals and extreme weather conditions.

Regulatory Standards and Certifications

Green concrete complies with evolving international regulatory standards such as ISO 21930 and LEED certification, emphasizing sustainability, reduced carbon emissions, and recyclable materials. Conventional concrete meets traditional standards like ASTM C150 and ACI 318, focusing primarily on structural performance and durability without stringent environmental criteria. Certifications for green concrete often include SITES and BREEAM, promoting eco-friendly construction practices beyond the requirements of conventional concrete standards.

Future Trends in Concrete Technology

Green concrete, incorporating recycled materials and industrial byproducts such as fly ash and slag, is shaping the future of sustainable construction by significantly reducing carbon footprints compared to conventional concrete. Innovations in nanotechnology and carbon capture techniques are enhancing the durability and strength of green concrete while minimizing environmental impact. Emerging trends emphasize eco-friendly binders, energy-efficient curing processes, and digital mixing optimization to meet global climate goals and build resilient infrastructure.

Green Concrete vs Conventional Concrete Infographic

materialdif.com

materialdif.com