Sandwich structures in composite pets consist of a lightweight core material bonded between two face sheets, providing enhanced stiffness and impact resistance with minimal weight increase. Laminate structures are made by stacking multiple composite layers with varying fiber orientations, offering superior strength and flexibility tailored to specific load requirements. The choice between sandwich and laminate structures depends on the desired balance of weight, mechanical properties, and application demands in composite pet design.

Table of Comparison

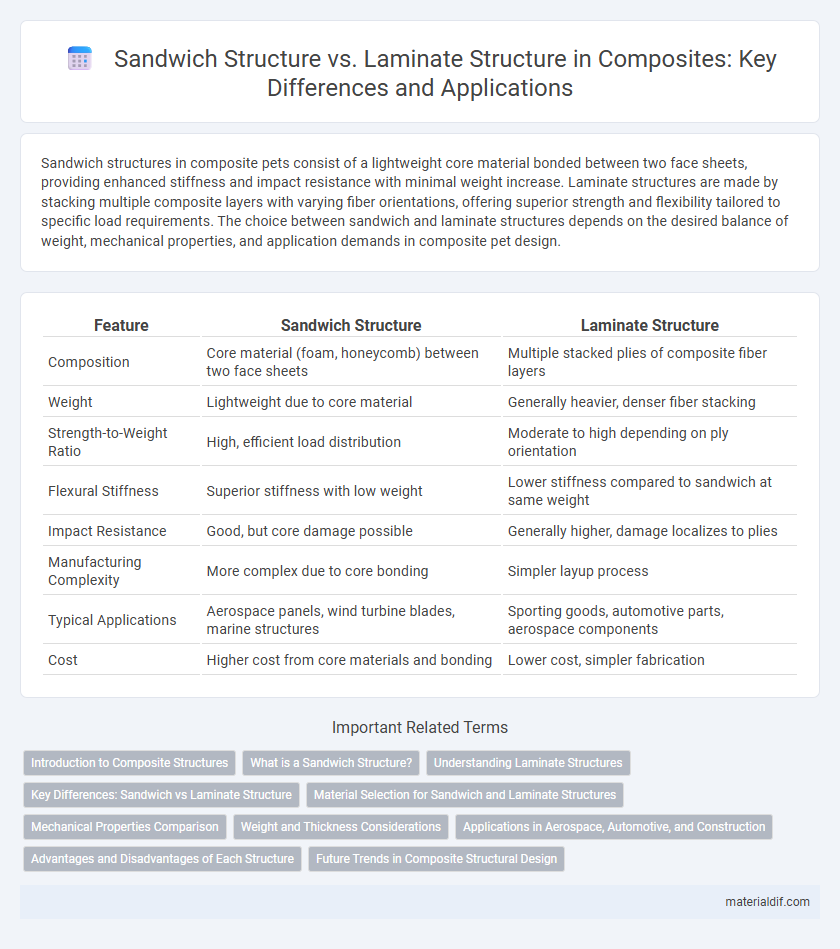

| Feature | Sandwich Structure | Laminate Structure |

|---|---|---|

| Composition | Core material (foam, honeycomb) between two face sheets | Multiple stacked plies of composite fiber layers |

| Weight | Lightweight due to core material | Generally heavier, denser fiber stacking |

| Strength-to-Weight Ratio | High, efficient load distribution | Moderate to high depending on ply orientation |

| Flexural Stiffness | Superior stiffness with low weight | Lower stiffness compared to sandwich at same weight |

| Impact Resistance | Good, but core damage possible | Generally higher, damage localizes to plies |

| Manufacturing Complexity | More complex due to core bonding | Simpler layup process |

| Typical Applications | Aerospace panels, wind turbine blades, marine structures | Sporting goods, automotive parts, aerospace components |

| Cost | Higher cost from core materials and bonding | Lower cost, simpler fabrication |

Introduction to Composite Structures

Composite structures are engineered materials composed of two or more distinct constituents that retain their separate identities while offering enhanced mechanical properties. Sandwich structures consist of a lightweight core material bonded between two strong face sheets, providing high stiffness-to-weight ratios ideal for aerospace and automotive applications. Laminate structures are made by stacking multiple layers of composite materials with varying fiber orientations, optimizing strength and durability through tailored anisotropic behavior.

What is a Sandwich Structure?

A sandwich structure consists of two strong, stiff face sheets bonded to a lightweight, thick core, creating a high strength-to-weight ratio ideal for aerospace, automotive, and marine applications. This configuration enhances bending stiffness and impact resistance while minimizing material use and weight compared to traditional laminate structures composed solely of stacked composite layers. The core material, often foam, honeycomb, or balsa wood, plays a critical role in maintaining the separation of face sheets and transferring shear forces efficiently.

Understanding Laminate Structures

Laminate structures consist of multiple bonded layers of composite materials, each with distinct fiber orientations to optimize mechanical properties like stiffness and strength. These layers work synergistically to resist various loads, providing tailored performance for aerospace and automotive applications. Understanding the stacking sequence and material selection in laminates is crucial for predicting failure modes and enhancing durability.

Key Differences: Sandwich vs Laminate Structure

Sandwich structures consist of two strong outer face sheets bonded to a lightweight core, offering high stiffness-to-weight ratios and superior impact resistance compared to laminate structures, which are made from multiple layers of fiber-reinforced materials stacked and bonded together. The core in sandwich structures provides enhanced load distribution and improved thermal insulation, while laminate structures focus on tailored fiber orientation to optimize strength and stiffness in specific directions. Sandwich structures excel in applications requiring lightweight and high bending strength, whereas laminate structures are preferred for complex load-bearing designs needing directional strength customization.

Material Selection for Sandwich and Laminate Structures

Material selection for sandwich structures centers on lightweight core materials such as foam, honeycomb, or balsa wood combined with high-strength face sheets like carbon fiber or fiberglass composites to maximize stiffness-to-weight ratio. Laminate structures rely on stacking layers of fiber-reinforced polymer composites, where fiber orientation, resin type, and ply sequence are critical parameters influencing mechanical properties. Optimizing material combinations in both structures enhances performance characteristics including strength, durability, and impact resistance for aerospace, automotive, and marine applications.

Mechanical Properties Comparison

Sandwich structures exhibit superior flexural stiffness and impact resistance compared to laminate structures due to their core materials distributing loads more efficiently and absorbing energy. Laminate structures, composed of stacked fiber-reinforced plies, offer higher tensile strength and better in-plane shear properties but generally lack the out-of-plane stiffness provided by sandwich cores. The choice between sandwich and laminate structures depends on application-specific mechanical performance requirements such as weight reduction, load distribution, and damage tolerance.

Weight and Thickness Considerations

Sandwich structures offer superior weight-to-thickness ratios compared to laminate structures, making them ideal for applications requiring lightweight and stiff components. The core material in sandwich structures significantly reduces overall weight while maintaining thickness for enhanced mechanical performance. Laminate structures tend to be denser and thicker, often resulting in higher weight for equivalent stiffness.

Applications in Aerospace, Automotive, and Construction

Sandwich structures with a lightweight core and strong face sheets offer superior stiffness-to-weight ratios, making them ideal for aerospace components, automotive body panels, and building facades that require high strength and impact resistance. Laminate structures, composed of stacked composite layers with varying fiber orientations, provide tailored mechanical properties and enhanced damage tolerance, widely applied in aerospace fuselage sections, automotive chassis parts, and load-bearing construction elements. Both structures optimize performance and material efficiency, with sandwich structures excelling in energy absorption and laminates delivering customized strength and flexibility across industries.

Advantages and Disadvantages of Each Structure

Sandwich structures offer superior strength-to-weight ratios and enhanced impact resistance due to their lightweight core materials combined with strong face sheets, making them ideal for aerospace and automotive applications requiring stiffness and energy absorption. Laminate structures provide excellent flexibility in tailoring mechanical properties through layer orientation, enabling precise control over strength and stiffness but tend to be heavier and less damage-tolerant compared to sandwich structures. While sandwich composites excel in reducing weight and improving fatigue performance, laminates are preferred for complex load-bearing components where customized anisotropy is critical.

Future Trends in Composite Structural Design

Future trends in composite structural design emphasize the integration of sandwich structures due to their superior strength-to-weight ratios and enhanced energy absorption capabilities compared to traditional laminate structures. Advances in smart materials and additive manufacturing enable the development of multifunctional sandwich composites with tailored mechanical properties for aerospace and automotive applications. The rise of predictive modeling and real-time structural health monitoring further drives optimized composite designs that extend service life and improve safety.

Sandwich Structure vs Laminate Structure Infographic

materialdif.com

materialdif.com