Gelcoat finish on composite PET surfaces provides a durable, glossy, and UV-resistant coating that enhances longevity and maintains aesthetic appeal without the need for frequent maintenance. In contrast, paint finish offers more color customization options but may require regular upkeep to prevent chipping, fading, and environmental damage. Choosing between gelcoat and paint finishes depends on the desired balance between durability and visual flexibility for composite PET applications.

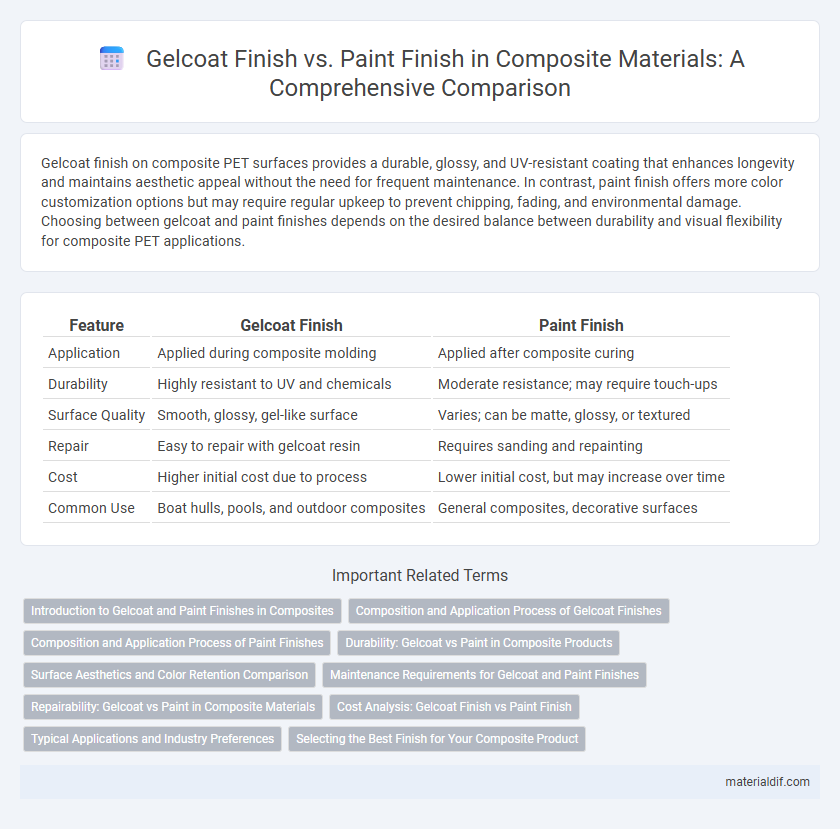

Table of Comparison

| Feature | Gelcoat Finish | Paint Finish |

|---|---|---|

| Application | Applied during composite molding | Applied after composite curing |

| Durability | Highly resistant to UV and chemicals | Moderate resistance; may require touch-ups |

| Surface Quality | Smooth, glossy, gel-like surface | Varies; can be matte, glossy, or textured |

| Repair | Easy to repair with gelcoat resin | Requires sanding and repainting |

| Cost | Higher initial cost due to process | Lower initial cost, but may increase over time |

| Common Use | Boat hulls, pools, and outdoor composites | General composites, decorative surfaces |

Introduction to Gelcoat and Paint Finishes in Composites

Gelcoat finish is a polyester or vinylester resin layer applied to composite surfaces, providing excellent UV resistance, durability, and a smooth, glossy appearance that protects the underlying fiberglass structure. Paint finish involves applying liquid coatings such as polyurethane or acrylic paint over composites, offering greater color variety and ease of touch-up but typically less impact resistance and longevity compared to gelcoat. Both finishes serve to enhance aesthetics and protect composite parts, with gelcoat often preferred for molds and marine applications due to its integrated protective properties.

Composition and Application Process of Gelcoat Finishes

Gelcoat finishes, primarily composed of polyester or vinyl ester resins combined with pigments and additives, form a durable, waterproof outer layer integral to composite materials. Applied during the molding process through spraying or brushing onto the mold surface, gelcoat cures to become a hard, protective skin that bonds seamlessly with the underlying fiberglass structure. Unlike paint finishes, which are applied after curing and provide primarily aesthetic benefits, gelcoat offers both structural protection and resistance to UV damage, chemicals, and moisture.

Composition and Application Process of Paint Finishes

Paint finishes typically consist of a mixture of pigments, binders, solvents, and additives, designed to provide color, protection, and durability. The application process involves surface preparation, including cleaning and sometimes priming, followed by multiple layers of paint applied through spraying, brushing, or rolling, with drying and curing stages in between. Advanced formulations allow customization for various substrates, enhancing adhesion and resistance to environmental factors.

Durability: Gelcoat vs Paint in Composite Products

Gelcoat finishes provide superior durability compared to paint finishes in composite products, offering enhanced resistance to UV exposure, abrasion, and chemical damage. The thickness and chemical composition of gelcoat create a robust protective layer that maintains structural integrity and appearance over time. Paint finishes, while visually versatile, typically require more frequent maintenance and are prone to chipping and fading under harsh environmental conditions.

Surface Aesthetics and Color Retention Comparison

Gelcoat finish offers superior surface aesthetics with a smooth, glossy appearance that resists fading, chipping, and cracking over time, maintaining vibrant color retention under UV exposure. Paint finish provides more color variety and customization options but tends to degrade faster due to environmental factors, often requiring more frequent maintenance. The inherent UV resistance in gelcoat makes it ideal for long-term durability and consistent color preservation on composite surfaces.

Maintenance Requirements for Gelcoat and Paint Finishes

Gelcoat finishes require minimal maintenance due to their durable, non-porous surface that resists UV damage and oxidation, making them ideal for long-term exposure to harsh marine environments. Paint finishes, while offering a wider range of colors and finishes, demand more frequent upkeep, including sanding, polishing, and reapplication to prevent peeling and fading caused by weathering. Proper care of gelcoat involves gentle cleaning with non-abrasive products, whereas painted surfaces require regular inspection to address chips and cracks to maintain aesthetic and protective qualities.

Repairability: Gelcoat vs Paint in Composite Materials

Gelcoat finish offers superior repairability in composite materials due to its ability to be easily sanded, polished, and blended with minimal surface disruption, maintaining the original texture and gloss. Paint finishes often require complete stripping and repainting to achieve a seamless repair, increasing labor and material costs. This makes gelcoat more cost-effective and practical for sustaining the appearance and integrity of composite structures over time.

Cost Analysis: Gelcoat Finish vs Paint Finish

Gelcoat finish generally demands a higher initial investment due to specialized materials and application techniques, but offers superior durability and longer lifespan, reducing long-term maintenance costs. Paint finish is typically more affordable upfront, with easier touch-up options, but may require frequent repainting and additional protective coatings, increasing cumulative expenses over time. Evaluating total cost of ownership highlights gelcoat as a cost-effective choice for heavy-use composites, while paint suits budget-conscious projects with lower durability requirements.

Typical Applications and Industry Preferences

Gelcoat finish is predominantly used in marine, automotive, and outdoor composite applications due to its durability, UV resistance, and smooth surface ideal for molding aesthetics. Paint finish is favored in industrial and architectural composites where color customization and ease of repair are prioritized over surface hardness. Industry preferences lean towards gelcoat for high-performance, weather-exposed products, while paint finishes dominate in sectors requiring frequent updates or specific color matching.

Selecting the Best Finish for Your Composite Product

Gelcoat finish offers superior durability and UV resistance, making it ideal for composite products exposed to harsh environments, while paint finish provides greater color customization and easier touch-up options. Gelcoat creates a harder, more impact-resistant surface that requires less maintenance over time compared to paint, which can chip or fade more quickly. For applications demanding long-term protection and aesthetic integrity, gelcoat is the preferred choice, whereas paint suits projects prioritizing flexibility in color and design updates.

Gelcoat Finish vs Paint Finish Infographic

materialdif.com

materialdif.com