Thermoplastic composites offer superior impact resistance and recyclability compared to thermosetting composites, which provide higher thermal stability and strength due to their cross-linked polymer structure. The ability to remelt thermoplastic composites enables easier reshaping and repair, while thermosetting composites, once cured, maintain their shape and structural integrity under extreme conditions. Selecting between these composites depends on specific application requirements such as durability, processing methods, and environmental considerations.

Table of Comparison

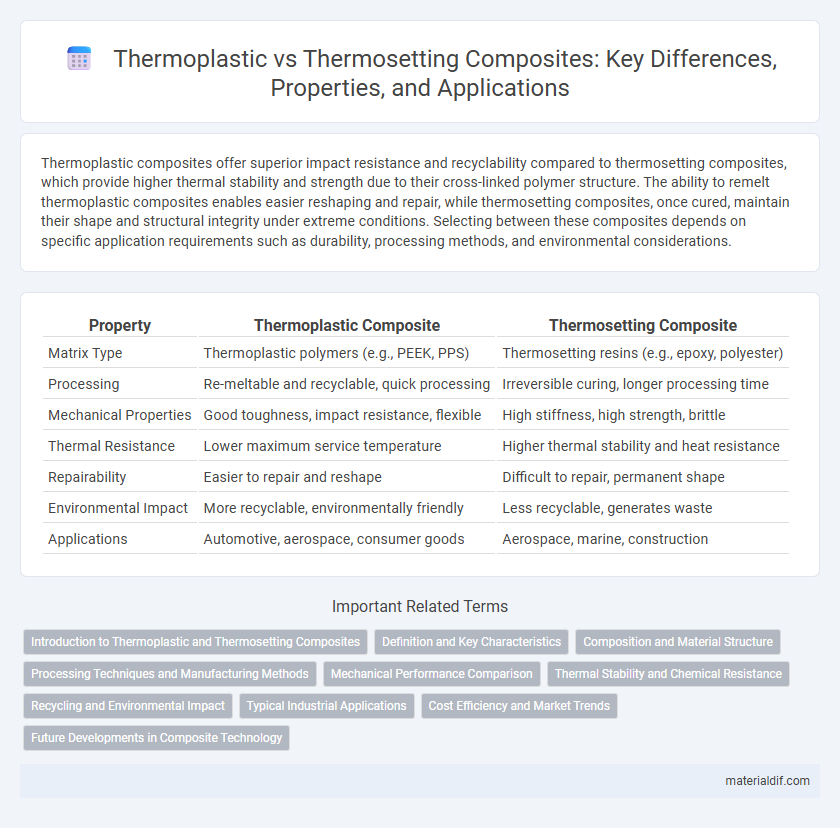

| Property | Thermoplastic Composite | Thermosetting Composite |

|---|---|---|

| Matrix Type | Thermoplastic polymers (e.g., PEEK, PPS) | Thermosetting resins (e.g., epoxy, polyester) |

| Processing | Re-meltable and recyclable, quick processing | Irreversible curing, longer processing time |

| Mechanical Properties | Good toughness, impact resistance, flexible | High stiffness, high strength, brittle |

| Thermal Resistance | Lower maximum service temperature | Higher thermal stability and heat resistance |

| Repairability | Easier to repair and reshape | Difficult to repair, permanent shape |

| Environmental Impact | More recyclable, environmentally friendly | Less recyclable, generates waste |

| Applications | Automotive, aerospace, consumer goods | Aerospace, marine, construction |

Introduction to Thermoplastic and Thermosetting Composites

Thermoplastic composites consist of a polymer matrix that softens when heated and hardens upon cooling, enabling easy reshaping and recycling. Thermosetting composites, on the other hand, are formed by polymers that irreversibly cure into a rigid structure through a chemical reaction, providing superior thermal stability and mechanical strength. These distinct molecular behaviors define their applications in aerospace, automotive, and structural engineering, where processing methods and durability requirements vary significantly.

Definition and Key Characteristics

Thermoplastic composites consist of a polymer matrix that softens when heated and hardens upon cooling, allowing for reshaping and recycling, while thermosetting composites have a matrix that irreversibly cures into a rigid structure after heat or chemical treatment. Key characteristics of thermoplastic composites include high impact resistance, flexibility, and faster processing times, whereas thermosetting composites are known for superior thermal stability, chemical resistance, and structural rigidity. The selection between thermoplastic and thermosetting composites depends on application requirements for durability, reusability, and environmental conditions.

Composition and Material Structure

Thermoplastic composites consist of a matrix made from thermoplastic polymers such as polypropylene or polyamide, which allow the material to melt and reshape upon heating. In contrast, thermosetting composites utilize a polymer matrix like epoxy or phenolic resin that undergoes a chemical curing process to form a rigid, cross-linked structure, providing high thermal and mechanical stability. The molecular structure of thermoplastics features linear or branched chains enabling recyclability, while thermosetting composites have a three-dimensional network of covalent bonds that create a permanent, infusible material.

Processing Techniques and Manufacturing Methods

Thermoplastic composites are processed using techniques such as injection molding, thermoforming, and automated fiber placement, which allow rapid heating, reshaping, and recycling due to their reversible melting behavior. Thermosetting composites rely on methods like hand lay-up, resin transfer molding (RTM), and vacuum-assisted resin infusion, where curing involves cross-linking reactions resulting in a rigid, irreversible matrix. The manufacturing of thermoplastics offers faster cycle times and enhanced toughness, whereas thermosetting composites provide superior thermal stability and chemical resistance, making each suitable for different industrial applications.

Mechanical Performance Comparison

Thermoplastic composites exhibit superior impact resistance and higher fracture toughness compared to thermosetting composites, making them ideal for applications requiring durability and damage tolerance. Thermosetting composites deliver greater stiffness and thermal stability due to their cross-linked polymer matrix, which enhances load-bearing capacity under high temperatures. The choice between thermoplastic and thermosetting composites depends on balancing mechanical strength, environmental resistance, and manufacturing requirements.

Thermal Stability and Chemical Resistance

Thermoplastic composites exhibit superior thermal stability due to their ability to soften and reform under heat without significant degradation, enabling repeated processing cycles. Their inherent chemical resistance is enhanced by the absence of cross-linked structures, making them more resistant to solvents and environmental stress cracking compared to thermosetting composites. Thermosetting composites, despite offering high thermal stability through rigid cross-linked polymer networks, tend to have lower chemical resistance and are prone to irreversible damage when exposed to harsh chemicals.

Recycling and Environmental Impact

Thermoplastic composites offer superior recyclability compared to thermosetting composites due to their ability to be remelted and reshaped, reducing landfill waste and supporting circular economy initiatives. Thermosetting composites, once cured, cannot be remelted or reprocessed, leading to significant environmental challenges related to disposal and incineration emissions. Advances in thermoplastic composite recycling technologies are driving reductions in carbon footprint and resource consumption, making them a more sustainable choice for industries focused on environmental impact mitigation.

Typical Industrial Applications

Thermoplastic composites are widely used in automotive and aerospace industries for applications requiring high impact resistance and rapid manufacturing cycles, such as structural components and interior parts. Thermosetting composites dominate in construction and marine sectors due to their superior thermal stability and mechanical strength, making them ideal for load-bearing elements and corrosion-resistant panels. Both materials offer unique benefits tailored to specific industrial demands, influencing their selection based on performance and production efficiency.

Cost Efficiency and Market Trends

Thermoplastic composites offer superior cost efficiency due to faster manufacturing cycles, recyclability, and lower energy consumption compared to thermosetting composites, which involve longer curing times and single-use matrices. Market trends indicate growing adoption of thermoplastic composites in automotive and aerospace sectors driven by demand for lightweight, sustainable materials and reduced lifecycle costs. Despite higher initial resin costs, thermoplastic composites' recyclability and potential for automation are accelerating their market share growth against traditional thermosetting composites.

Future Developments in Composite Technology

Future developments in composite technology will enhance the recyclability and sustainability of thermoplastic composites through advanced molecular reforming techniques and improved thermal stability. Thermosetting composites are expected to see innovations in reversible curing processes and nano-engineered resins that increase mechanical performance and reduce environmental impact. Integration of smart sensing materials in both thermoplastic and thermosetting composites will enable real-time structural health monitoring and predictive maintenance, driving industry transformation.

Thermoplastic composite vs Thermosetting composite Infographic

materialdif.com

materialdif.com