Unidirectional laminates provide superior strength and stiffness along a single axis, making them ideal for applications requiring high tensile performance in one direction. Cross-ply laminates, composed of alternating layers oriented at 90 degrees, offer enhanced multidirectional strength and improved resistance to delamination under complex loading conditions. Choosing between unidirectional and cross-ply laminates depends on the specific mechanical requirements and load distribution of the composite part.

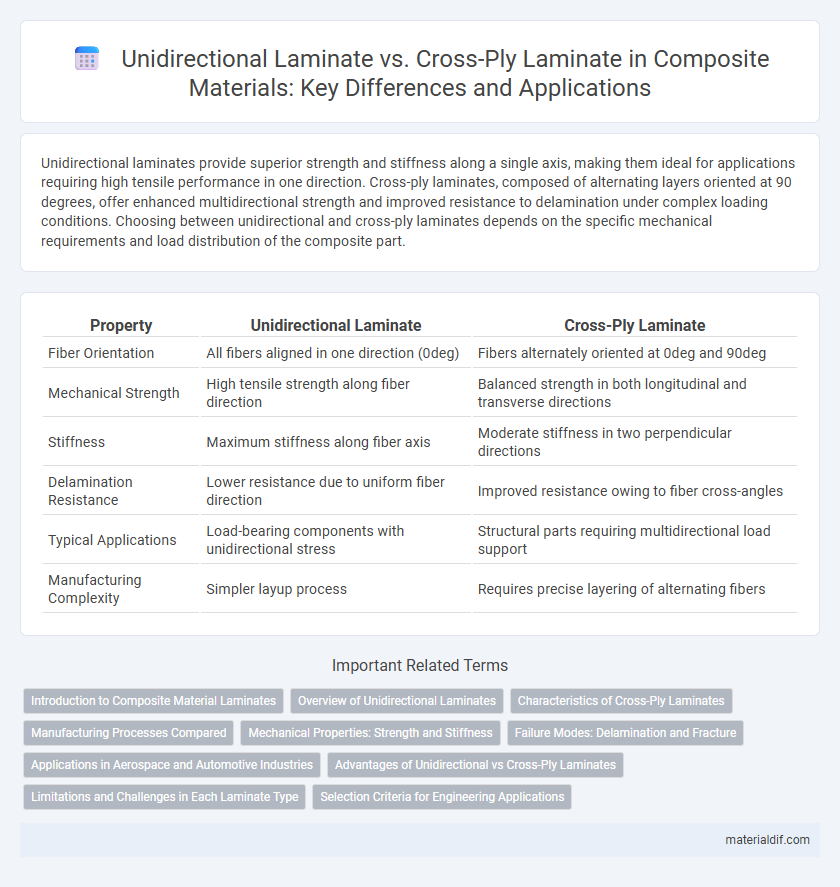

Table of Comparison

| Property | Unidirectional Laminate | Cross-Ply Laminate |

|---|---|---|

| Fiber Orientation | All fibers aligned in one direction (0deg) | Fibers alternately oriented at 0deg and 90deg |

| Mechanical Strength | High tensile strength along fiber direction | Balanced strength in both longitudinal and transverse directions |

| Stiffness | Maximum stiffness along fiber axis | Moderate stiffness in two perpendicular directions |

| Delamination Resistance | Lower resistance due to uniform fiber direction | Improved resistance owing to fiber cross-angles |

| Typical Applications | Load-bearing components with unidirectional stress | Structural parts requiring multidirectional load support |

| Manufacturing Complexity | Simpler layup process | Requires precise layering of alternating fibers |

Introduction to Composite Material Laminates

Unidirectional laminates in composite materials consist of fibers aligned in a single direction, offering high strength and stiffness along that axis but limited resistance to loads perpendicular to the fibers. Cross-ply laminates alternate fiber orientations, typically at 0deg and 90deg, enhancing multidirectional strength and improving overall structural performance. The choice between unidirectional and cross-ply laminates depends on the specific load requirements and mechanical properties needed for the composite structure.

Overview of Unidirectional Laminates

Unidirectional laminates consist of fibers aligned in a single direction, providing maximum strength and stiffness along the fiber axis. These laminates are typically used where load transfer is predominantly unidirectional, offering superior tensile and compressive properties compared to cross-ply laminates. The high fiber volume fraction and minimal matrix influence result in enhanced mechanical performance tailored for specific engineering applications such as aerospace and automotive structures.

Characteristics of Cross-Ply Laminates

Cross-ply laminates feature alternating layers oriented at 0deg and 90deg, enhancing in-plane stiffness and strength in multiple directions. This laminate configuration improves resistance to delamination and balances mechanical properties under tensile and bending loads. The orthogonal fiber arrangement also reduces anisotropic behavior, making cross-ply laminates suitable for structural composite applications requiring uniform performance.

Manufacturing Processes Compared

Unidirectional laminates involve aligning fibers in a single direction, simplifying the layup and curing processes, which enhances manufacturing efficiency but limits isotropic strength. Cross-ply laminates consist of alternating fiber orientations, typically at 0deg and 90deg, requiring more complex stacking sequences and precise alignment during layup, increasing production time and potential for defects. The added complexity in cross-ply manufacturing results in superior multidirectional mechanical properties but demands stringent quality control measures and advanced curing cycles.

Mechanical Properties: Strength and Stiffness

Unidirectional laminates exhibit high strength and stiffness primarily along the fiber direction, making them ideal for applications requiring maximum load-bearing capacity in one orientation. Cross-ply laminates, composed of alternating fiber angles (e.g., 0deg/90deg), offer improved isotropic mechanical properties, balancing strength and stiffness across multiple directions. The anisotropic nature of unidirectional laminates results in superior longitudinal tensile strength, while cross-ply laminates enhance resistance to transverse stresses and improve overall structural stability.

Failure Modes: Delamination and Fracture

Unidirectional laminates primarily experience delamination due to their fiber alignment, which creates weak interfaces under transverse loading, while fracture often occurs along fiber directions under tensile stress. Cross-ply laminates exhibit more complex failure modes, as alternating fiber orientations improve resistance to delamination but introduce matrix cracking and interlaminar shear failure between plies. The selection between unidirectional and cross-ply laminates significantly influences the initiation and propagation of delamination and fracture, impacting overall composite durability in structural applications.

Applications in Aerospace and Automotive Industries

Unidirectional laminates provide high tensile strength and stiffness along the fiber direction, making them ideal for aerospace applications requiring lightweight structural components such as wing spars and fuselage frames. Cross-ply laminates offer balanced mechanical properties and improved resistance to delamination, commonly used in automotive body panels and chassis parts to enhance durability and impact resistance. Both laminate types optimize performance by aligning fiber orientation with load paths specific to aerospace and automotive engineering demands.

Advantages of Unidirectional vs Cross-Ply Laminates

Unidirectional laminates provide superior tensile strength and stiffness along the fiber direction, making them ideal for load-bearing applications requiring high performance. Their simplified fiber orientation results in predictable mechanical properties and reduced delamination risk compared to cross-ply laminates, which have multiple fiber angles but lower strength in any single direction. This makes unidirectional laminates especially advantageous in aerospace and automotive industries where directional load efficiency is critical.

Limitations and Challenges in Each Laminate Type

Unidirectional laminates exhibit limited load transfer capabilities primarily along the fiber direction, resulting in reduced transverse strength and increased susceptibility to cracking under multi-axial stress. Cross-ply laminates face challenges related to interlaminar shear stresses and delamination between layers oriented at different angles, which compromise structural integrity under fatigue loading. Both laminate types encounter difficulties in balancing stiffness and damage tolerance, necessitating careful design optimization for specific composite applications.

Selection Criteria for Engineering Applications

Unidirectional laminates exhibit superior tensile strength and stiffness along the fiber direction, making them ideal for components subjected to unidirectional loads such as aerospace wing spars and wind turbine blades. Cross-ply laminates offer enhanced multidirectional strength and balanced mechanical properties, suitable for structural applications requiring resistance to both tensile and shear stresses like automotive panels and pressure vessels. Selection criteria hinge on load conditions, required stiffness, and dimensional stability, with unidirectional laminates favored for anisotropic stress and cross-ply laminates preferred for complex loading environments.

Unidirectional laminate vs Cross-ply laminate Infographic

materialdif.com

materialdif.com