Resin Infusion offers superior control over resin flow and reduces void content by utilizing vacuum pressure to draw resin through dry fiber reinforcements, ensuring high-quality, lightweight composite parts. Resin Transfer Molding injects resin into a closed mold under pressure, allowing faster cycle times and suitability for complex geometries but may result in slightly higher porosity compared to infusion. Selecting between Resin Infusion and Resin Transfer Molding depends on the desired balance between production speed, part complexity, and mechanical performance requirements.

Table of Comparison

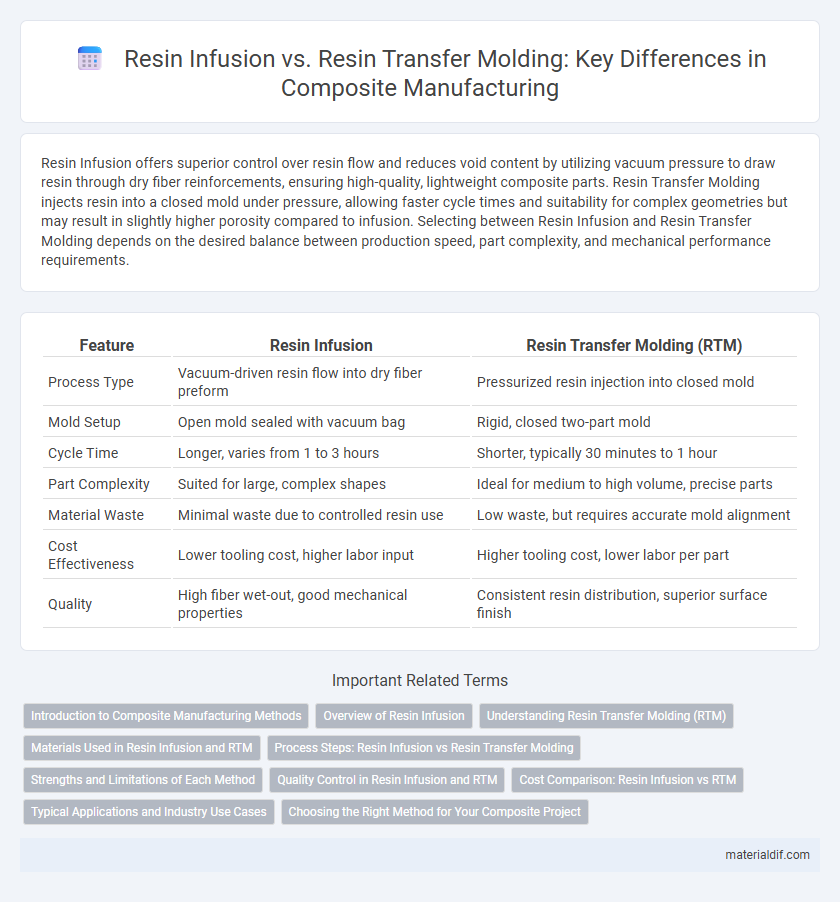

| Feature | Resin Infusion | Resin Transfer Molding (RTM) |

|---|---|---|

| Process Type | Vacuum-driven resin flow into dry fiber preform | Pressurized resin injection into closed mold |

| Mold Setup | Open mold sealed with vacuum bag | Rigid, closed two-part mold |

| Cycle Time | Longer, varies from 1 to 3 hours | Shorter, typically 30 minutes to 1 hour |

| Part Complexity | Suited for large, complex shapes | Ideal for medium to high volume, precise parts |

| Material Waste | Minimal waste due to controlled resin use | Low waste, but requires accurate mold alignment |

| Cost Effectiveness | Lower tooling cost, higher labor input | Higher tooling cost, lower labor per part |

| Quality | High fiber wet-out, good mechanical properties | Consistent resin distribution, superior surface finish |

Introduction to Composite Manufacturing Methods

Resin infusion and resin transfer molding (RTM) are advanced composite manufacturing methods used to achieve high-strength, lightweight structures. Resin infusion involves injecting resin through a dry fiber layup under vacuum, optimizing fiber wet-out and reducing void content. RTM uses a closed mold where resin is injected under pressure, enabling precise control over part geometry and excellent surface finish on both sides.

Overview of Resin Infusion

Resin infusion is a composite manufacturing process where dry fiber reinforcements are placed in a mold and resin is drawn through the fibers using vacuum pressure, ensuring thorough impregnation and reduced void content. This method offers high structural integrity and a lightweight finish, commonly used in aerospace, marine, and automotive industries for large or complex parts. Compared to Resin Transfer Molding, resin infusion allows for greater control over resin flow and minimizes emissions, making it ideal for environmentally sensitive applications.

Understanding Resin Transfer Molding (RTM)

Resin Transfer Molding (RTM) is a closed-mold composite manufacturing process where resin is injected into a mold cavity containing a dry fiber preform, ensuring uniform resin distribution and reducing void content. RTM offers superior surface finish and complex shape capability compared to open-mold techniques, making it ideal for high-performance composite parts in aerospace and automotive industries. The process's controlled environment enhances mechanical properties, making RTM a preferred choice for producing consistent, high-quality composite components.

Materials Used in Resin Infusion and RTM

Resin infusion typically employs low-viscosity thermosetting resins such as epoxy, polyester, or vinyl ester to ensure thorough fiber impregnation under vacuum pressure. Resin Transfer Molding (RTM) utilizes similar resins but favors higher viscosity formulations to optimize flow within the closed mold cavity. The choice between resin types in both processes significantly influences composite properties like strength, weight, and curing time.

Process Steps: Resin Infusion vs Resin Transfer Molding

Resin infusion involves placing dry fiber reinforcements in a mold, sealing it with a vacuum bag, and drawing resin through the fibers using vacuum pressure, ensuring complete wet-out and minimal air entrapment. Resin transfer molding (RTM) entails injecting resin under pressure into a closed mold containing pre-positioned fibers, allowing faster cycle times and precise control over resin flow and fiber saturation. Both methods require careful mold preparation and fiber placement but differ primarily in resin delivery, impacting production speed and part consistency.

Strengths and Limitations of Each Method

Resin infusion offers excellent control over fiber wet-out, resulting in consistently high-quality laminates with reduced void content, ideal for large, complex composite structures but requires a sealed vacuum environment and longer curing times. Resin transfer molding (RTM) enables faster cycle times and better repeatability suitable for high-volume production, though it may suffer from resin flow front challenges leading to potential dry spots in intricate geometries. Both methods provide strong mechanical properties, but resin infusion excels in flexibility and large-part manufacturing while RTM is advantageous for precision and automated mass production.

Quality Control in Resin Infusion and RTM

Quality control in Resin Infusion involves monitoring vacuum levels and resin flow rates to prevent voids and ensure uniform fiber wet-out, critical for structural integrity in composite parts. In Resin Transfer Molding (RTM), quality control emphasizes precise resin injection pressure and mold temperature regulation to minimize defects such as dry spots and optimize resin distribution. Both processes require real-time sensors and thorough post-curing inspections to guarantee composite performance and consistency.

Cost Comparison: Resin Infusion vs RTM

Resin infusion offers lower upfront tooling costs and greater flexibility for small to medium production runs compared to Resin Transfer Molding (RTM), which requires expensive, high-precision molds increasing initial capital investment. RTM provides faster cycle times and higher production rates, making it more cost-effective for large-scale manufacturing despite its higher tooling and setup expenses. The overall cost comparison depends on factors such as production volume, part complexity, and application requirements, with resin infusion favored for low-to-mid volume and RTM preferred for high-volume, consistent quality composite parts.

Typical Applications and Industry Use Cases

Resin Infusion is commonly used in large, complex composite structures such as aerospace components, wind turbine blades, and marine vessels due to its ability to produce high-strength, void-free laminates with excellent fiber wet-out. Resin Transfer Molding (RTM) is favored in automotive and industrial applications for manufacturing medium to high-volume, geometrically intricate parts with tight tolerances and enhanced surface finishes. Both methods are integral in industries demanding lightweight, durable, and cost-effective composite solutions, with Resin Infusion excelling in large-scale structural parts and RTM preferred for precision, repeatability, and faster cycle times.

Choosing the Right Method for Your Composite Project

Resin infusion offers superior control over fiber wet-out and minimal void content, making it ideal for large, complex composite structures requiring high strength-to-weight ratios. Resin transfer molding (RTM) delivers faster cycle times and excellent surface finishes on both sides, suitable for high-volume production of moderately sized parts. Selecting the appropriate method depends on factors such as part size, production volume, mechanical property requirements, and cost constraints.

Resin Infusion vs Resin Transfer Molding Infographic

materialdif.com

materialdif.com