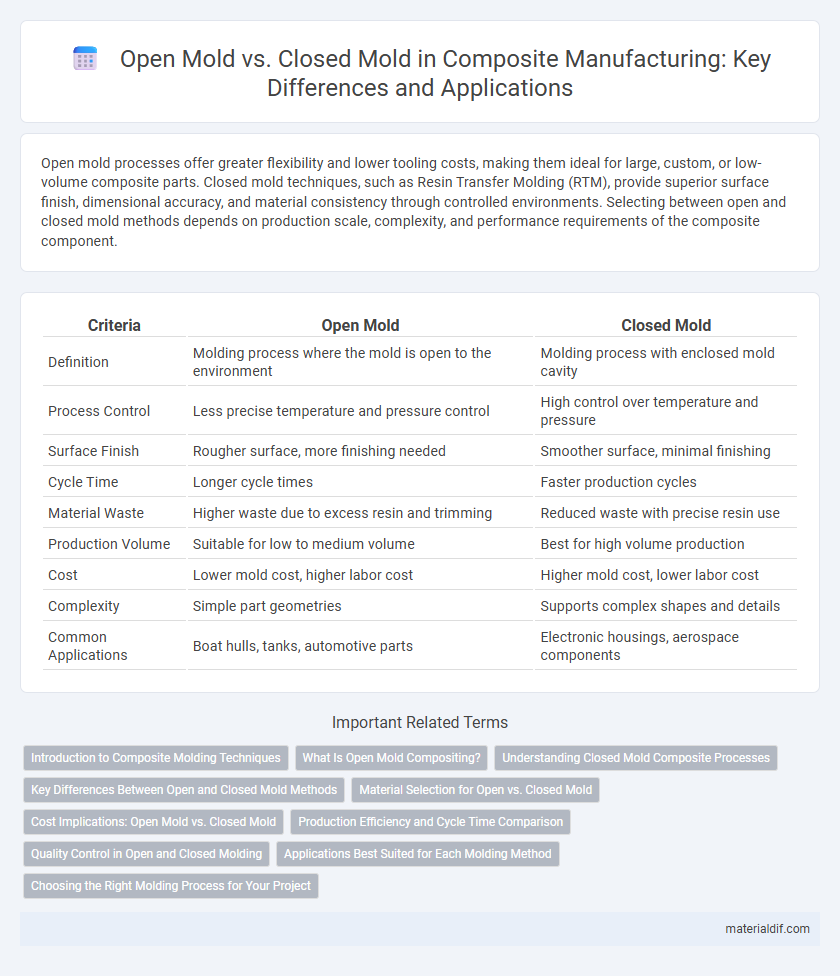

Open mold processes offer greater flexibility and lower tooling costs, making them ideal for large, custom, or low-volume composite parts. Closed mold techniques, such as Resin Transfer Molding (RTM), provide superior surface finish, dimensional accuracy, and material consistency through controlled environments. Selecting between open and closed mold methods depends on production scale, complexity, and performance requirements of the composite component.

Table of Comparison

| Criteria | Open Mold | Closed Mold |

|---|---|---|

| Definition | Molding process where the mold is open to the environment | Molding process with enclosed mold cavity |

| Process Control | Less precise temperature and pressure control | High control over temperature and pressure |

| Surface Finish | Rougher surface, more finishing needed | Smoother surface, minimal finishing |

| Cycle Time | Longer cycle times | Faster production cycles |

| Material Waste | Higher waste due to excess resin and trimming | Reduced waste with precise resin use |

| Production Volume | Suitable for low to medium volume | Best for high volume production |

| Cost | Lower mold cost, higher labor cost | Higher mold cost, lower labor cost |

| Complexity | Simple part geometries | Supports complex shapes and details |

| Common Applications | Boat hulls, tanks, automotive parts | Electronic housings, aerospace components |

Introduction to Composite Molding Techniques

Open mold composite molding involves shaping materials on one mold surface exposed to the environment, commonly used for large or complex parts due to its cost-effectiveness and flexibility. Closed mold techniques, such as resin transfer molding (RTM) and compression molding, encase the material between two mold halves, enhancing precision, surface finish, and reducing emissions. Selecting between open and closed mold methods depends on factors like production volume, part complexity, and desired mechanical properties.

What Is Open Mold Compositing?

Open mold compositing involves creating composite parts by applying resin and reinforcement materials directly onto a reusable open mold surface, exposing the part to air during curing. This process is commonly used for large, simple-shaped components such as boat hulls, automotive body panels, and storage tanks due to its cost-effectiveness and ease of production. The open mold method allows for visual inspection during fabrication but may result in lower surface finish quality and increased exposure to volatile organic compounds (VOCs) compared to closed mold techniques.

Understanding Closed Mold Composite Processes

Closed mold composite processes involve the use of two or more matched mold halves that enclose the reinforcement and resin, enabling precise control over fiber placement and resin distribution. Techniques such as resin transfer molding (RTM) and vacuum-assisted resin transfer molding (VARTM) reduce void content and improve surface finish, resulting in stronger and more consistent composite parts. The controlled environment of closed molds enhances repeatability and allows for complex shapes with reduced emissions compared to open mold methods.

Key Differences Between Open and Closed Mold Methods

Open mold methods involve applying composite materials onto an exposed mold surface, allowing easy access for manual layup and curing, which results in lower tooling costs but higher risk of contamination and lower repeatability. Closed mold techniques use matched mold halves enclosing the composite material, enabling better control of fiber orientation, resin flow, and pressure, which enhances product consistency, surface finish, and mechanical properties. The key differences include mold complexity, production volume suitability, material waste, and overall part quality, with open molds preferred for prototypes and custom parts, while closed molds support high-volume, precision manufacturing.

Material Selection for Open vs. Closed Mold

Material selection for open mold processes typically involves thermosetting resins like polyester or vinyl ester due to their ease of use and cost-effectiveness in open environments. Closed mold techniques favor advanced resin systems such as epoxy and polyurethane that offer superior mechanical properties and controlled curing, essential for high-performance composite parts. The choice between open and closed mold processes significantly impacts resin formulation, fiber compatibility, and overall composite quality.

Cost Implications: Open Mold vs. Closed Mold

Open mold processes typically incur lower initial tooling costs, making them suitable for low-volume composite production, but higher labor and finishing expenses can increase total costs over time. Closed mold techniques, such as resin transfer molding (RTM), involve higher upfront investment in molds, yet offer reduced material waste and faster cycle times that lower per-part costs in high-volume manufacturing. Evaluating cost implications requires balancing mold fabrication expenses against production efficiency and volume requirements for composite parts.

Production Efficiency and Cycle Time Comparison

Open mold processes typically offer faster cycle times due to simpler mold designs and easier part removal, enhancing production efficiency for low to medium volume runs. Closed mold techniques, such as resin transfer molding (RTM), enable higher precision and repeatability, reducing material waste and improving overall throughput despite longer initial cycle times. Evaluating production efficiency requires balancing the rapid turnaround of open molds against the quality control and scalability advantages inherent in closed mold systems.

Quality Control in Open and Closed Molding

Quality control in open mold processes relies heavily on operator skill and visual inspection to manage surface finish and dimensional accuracy, often resulting in higher variability. Closed mold techniques, such as resin transfer molding (RTM), offer superior quality control by enclosing the composite material within a fixed cavity, enabling consistent fiber placement and resin distribution, which improves repeatability and reduces void content. Advanced monitoring systems in closed molding further enhance defect detection and process standardization, ensuring higher overall product quality.

Applications Best Suited for Each Molding Method

Open mold processes excel in large-scale, low-volume applications such as automotive parts, boat hulls, and wind turbine blades due to their cost-effectiveness and flexibility in handling complex shapes. Closed mold methods, including resin transfer molding (RTM) and compression molding, are ideal for high-volume production of precision components like aerospace parts, electronic enclosures, and structural composites because of their superior surface finish and enhanced mechanical properties. Selecting between open and closed mold depends on factors like production volume, component complexity, and desired material performance.

Choosing the Right Molding Process for Your Project

Selecting the right molding process for your composite project hinges on the specific requirements of part complexity, production volume, and material properties. Open mold processes, such as hand lay-up and spray-up, offer cost-effective solutions for low-volume or large parts with moderate precision, while closed mold methods like resin transfer molding (RTM) and vacuum infusion provide superior surface finish, dimensional accuracy, and environmental control beneficial for high-performance composites. Evaluating factors like mold cost, cycle time, and part quality ensures an optimized manufacturing approach tailored to your project's technical and economic goals.

Open Mold vs Closed Mold Infographic

materialdif.com

materialdif.com