CFRP offers superior strength-to-weight ratio and stiffness compared to GFRP, making it ideal for high-performance aerospace and automotive applications. GFRP is more cost-effective and provides excellent corrosion resistance, often preferred in construction and marine environments. Both materials exhibit excellent fatigue resistance, but CFRP's higher strength makes it suitable for structural components requiring minimal weight.

Table of Comparison

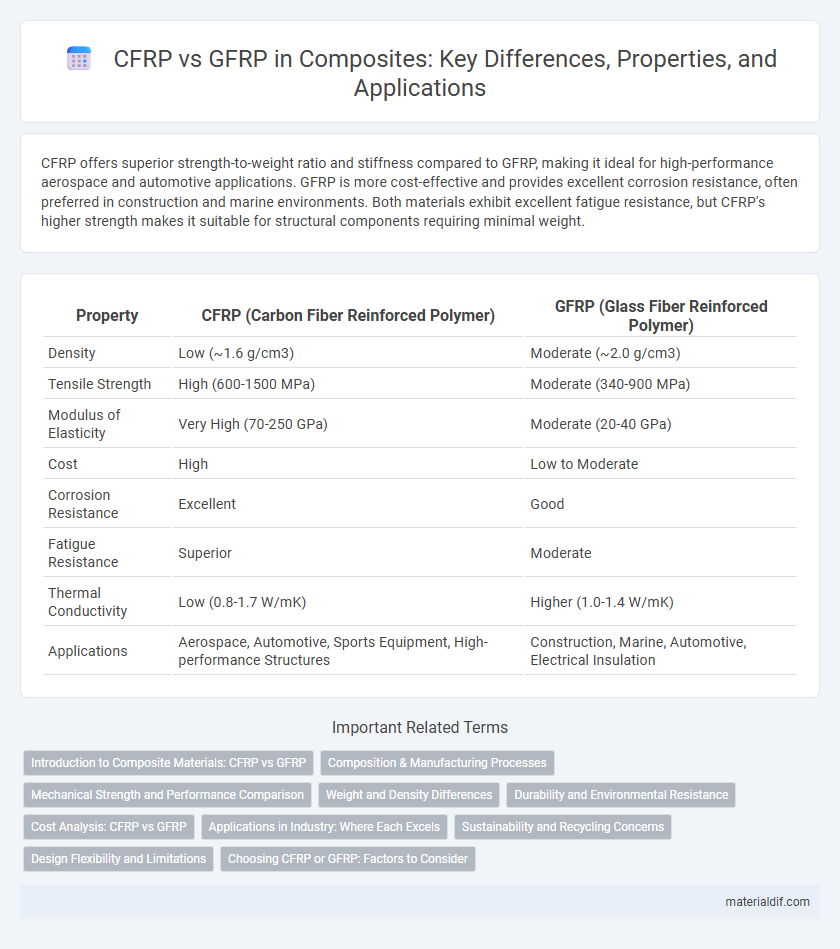

| Property | CFRP (Carbon Fiber Reinforced Polymer) | GFRP (Glass Fiber Reinforced Polymer) |

|---|---|---|

| Density | Low (~1.6 g/cm3) | Moderate (~2.0 g/cm3) |

| Tensile Strength | High (600-1500 MPa) | Moderate (340-900 MPa) |

| Modulus of Elasticity | Very High (70-250 GPa) | Moderate (20-40 GPa) |

| Cost | High | Low to Moderate |

| Corrosion Resistance | Excellent | Good |

| Fatigue Resistance | Superior | Moderate |

| Thermal Conductivity | Low (0.8-1.7 W/mK) | Higher (1.0-1.4 W/mK) |

| Applications | Aerospace, Automotive, Sports Equipment, High-performance Structures | Construction, Marine, Automotive, Electrical Insulation |

Introduction to Composite Materials: CFRP vs GFRP

Carbon Fiber Reinforced Polymer (CFRP) and Glass Fiber Reinforced Polymer (GFRP) are two primary types of composite materials widely utilized in aerospace, automotive, and construction industries due to their high strength-to-weight ratios and corrosion resistance. CFRP offers superior tensile strength, stiffness, and fatigue resistance compared to GFRP, making it ideal for high-performance applications despite its higher cost. GFRP provides excellent impact resistance and cost-efficiency, making it suitable for less demanding structural components where weight and budget constraints are critical.

Composition & Manufacturing Processes

CFRP consists of carbon fibers embedded in a polymer matrix, typically epoxy, offering high tensile strength and rigidity due to the alignment of carbon fibers. GFRP is composed of glass fibers within a polymer resin, usually polyester or vinyl ester, providing good corrosion resistance and cost-effectiveness but lower strength compared to CFRP. Manufacturing CFRP involves precise layup or filament winding followed by curing cycles in autoclaves, whereas GFRP is commonly produced through hand layup, spray-up, or resin transfer molding techniques with shorter curing times.

Mechanical Strength and Performance Comparison

Carbon Fiber Reinforced Polymer (CFRP) exhibits superior mechanical strength compared to Glass Fiber Reinforced Polymer (GFRP), with tensile strength typically ranging from 3,500 to 6,000 MPa, while GFRP averages around 2,000 to 3,500 MPa. CFRP's higher stiffness, with a modulus of elasticity between 70 to 300 GPa, surpasses GFRP's 20 to 40 GPa, resulting in enhanced performance under high stress and load applications. The superior fatigue resistance and low weight-to-strength ratio of CFRP make it the preferred choice for aerospace, automotive, and high-performance engineering compared to GFRP, which remains cost-effective for moderate strength requirements.

Weight and Density Differences

CFRP features a lower density of approximately 1.6 g/cm3 compared to GFRP's density of about 2.0 g/cm3, making CFRP significantly lighter for equivalent volume. This weight advantage translates into enhanced performance in aerospace and automotive applications where reducing mass is critical. The superior strength-to-weight ratio of CFRP enables structural designs with higher rigidity without increasing component weight.

Durability and Environmental Resistance

CFRP (Carbon Fiber Reinforced Polymer) exhibits superior durability and environmental resistance compared to GFRP (Glass Fiber Reinforced Polymer) due to its higher tensile strength and better resistance to corrosion and UV degradation. The carbon fibers in CFRP provide enhanced fatigue resistance and stability in harsh chemical or marine environments, extending the lifespan of structural components. In contrast, GFRP is more susceptible to moisture absorption and alkali attack, which can lead to reduced mechanical properties and faster material degradation over time.

Cost Analysis: CFRP vs GFRP

CFRP (Carbon Fiber Reinforced Polymer) generally incurs higher material and manufacturing costs compared to GFRP (Glass Fiber Reinforced Polymer) due to expensive raw materials and more complex processing techniques. GFRP offers a cost-effective solution with lower material costs and simpler fabrication, making it suitable for large-scale, budget-sensitive applications. The price differential significantly impacts project feasibility, where CFRP excels in high-performance, weight-sensitive uses, and GFRP remains preferred for economical and moderate-strength requirements.

Applications in Industry: Where Each Excels

CFRP offers superior strength-to-weight ratio and stiffness, making it ideal for aerospace, automotive, and high-performance sports equipment where weight reduction and structural integrity are critical. GFRP provides excellent corrosion resistance and cost-effectiveness, excelling in marine, construction, and infrastructure applications where durability and budget constraints are prioritized. Industry-specific requirements dictate the choice between CFRP's advanced mechanical properties and GFRP's economic advantages and environmental resistance.

Sustainability and Recycling Concerns

CFRP offers superior strength-to-weight ratio compared to GFRP, yet its recycling remains challenging due to the thermal degradation of carbon fibers during reprocessing. In contrast, GFRP involves less environmental impact during disposal but suffers from lower mechanical performance and durability, leading to shorter service life and potentially more frequent replacements. Innovations in chemical and mechanical recycling of both CFRP and GFRP aim to improve sustainability by recovering fibers and matrix materials while reducing landfill waste and energy consumption.

Design Flexibility and Limitations

CFRP offers superior design flexibility due to its higher tensile strength and stiffness, enabling complex shapes and thinner constructions in advanced aerospace and automotive applications. GFRP, while more cost-effective and corrosion-resistant, has limitations in weight and structural performance, restricting its use in high-performance designs. Designers must consider CFRP's sensitivity to impact damage and higher material costs against GFRP's ease of fabrication and broader availability.

Choosing CFRP or GFRP: Factors to Consider

When choosing between CFRP and GFRP, factors such as tensile strength, weight, cost, and environmental resistance are critical. CFRP offers superior strength-to-weight ratio and stiffness, making it ideal for high-performance applications, whereas GFRP is more cost-effective and provides better impact resistance and corrosion resistance. Consider project requirements including budget constraints, mechanical properties, and durability when selecting the appropriate fiber-reinforced polymer.

CFRP (Carbon Fiber Reinforced Polymer) vs GFRP (Glass Fiber Reinforced Polymer) Infographic

materialdif.com

materialdif.com