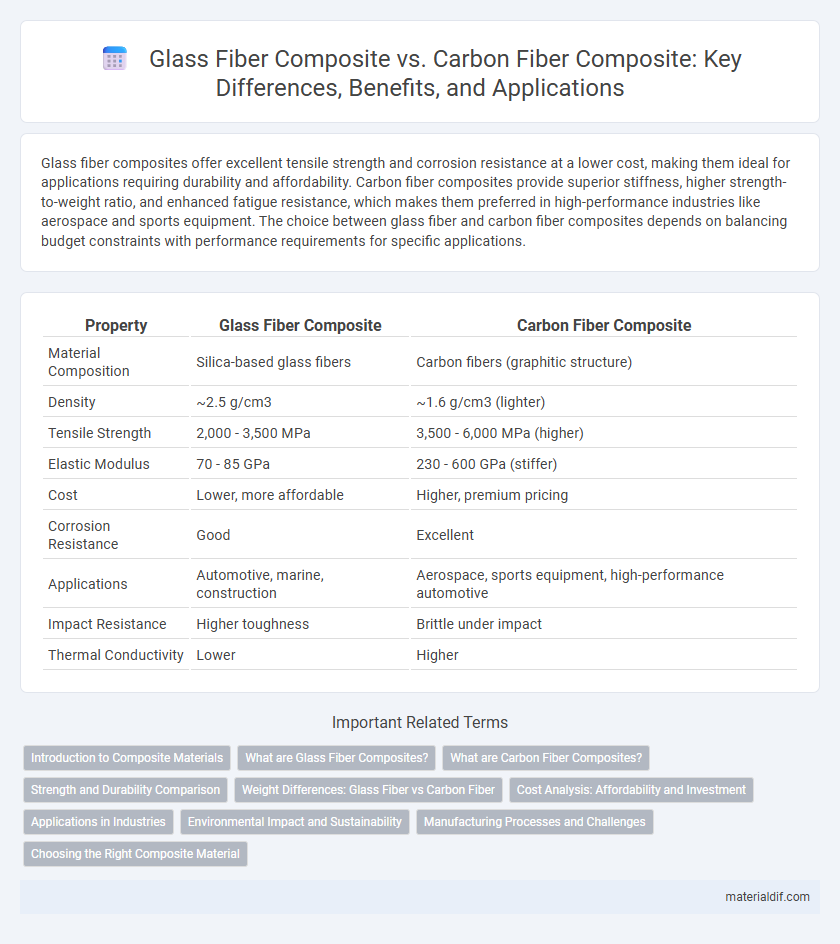

Glass fiber composites offer excellent tensile strength and corrosion resistance at a lower cost, making them ideal for applications requiring durability and affordability. Carbon fiber composites provide superior stiffness, higher strength-to-weight ratio, and enhanced fatigue resistance, which makes them preferred in high-performance industries like aerospace and sports equipment. The choice between glass fiber and carbon fiber composites depends on balancing budget constraints with performance requirements for specific applications.

Table of Comparison

| Property | Glass Fiber Composite | Carbon Fiber Composite |

|---|---|---|

| Material Composition | Silica-based glass fibers | Carbon fibers (graphitic structure) |

| Density | ~2.5 g/cm3 | ~1.6 g/cm3 (lighter) |

| Tensile Strength | 2,000 - 3,500 MPa | 3,500 - 6,000 MPa (higher) |

| Elastic Modulus | 70 - 85 GPa | 230 - 600 GPa (stiffer) |

| Cost | Lower, more affordable | Higher, premium pricing |

| Corrosion Resistance | Good | Excellent |

| Applications | Automotive, marine, construction | Aerospace, sports equipment, high-performance automotive |

| Impact Resistance | Higher toughness | Brittle under impact |

| Thermal Conductivity | Lower | Higher |

Introduction to Composite Materials

Glass fiber composites offer excellent tensile strength, corrosion resistance, and cost-effectiveness, making them ideal for automotive, construction, and marine applications. Carbon fiber composites provide superior stiffness, higher strength-to-weight ratios, and enhanced fatigue resistance, favored in aerospace, sports equipment, and high-performance engineering industries. Both materials combine polymer matrices with reinforcing fibers, optimizing mechanical properties through fiber orientation and composite layering techniques.

What are Glass Fiber Composites?

Glass fiber composites consist of fine glass fibers embedded in a resin matrix, commonly polyester or epoxy, providing excellent tensile strength and durability. These composites offer high impact resistance, corrosion resistance, and cost-effectiveness, making them ideal for automotive, marine, and construction applications. Glass fiber composites typically exhibit lower stiffness and weight compared to carbon fiber composites, but their affordability and versatile manufacturing processes drive widespread use.

What are Carbon Fiber Composites?

Carbon fiber composites consist of carbon fibers embedded in a polymer matrix, offering exceptional strength-to-weight ratio and high stiffness. These composites are widely used in aerospace, automotive, and sporting goods industries due to their superior mechanical properties and resistance to corrosion. Compared to glass fiber composites, carbon fiber composites deliver enhanced performance in applications demanding lightweight materials with outstanding durability.

Strength and Durability Comparison

Glass fiber composites offer high tensile strength and excellent durability at a lower cost, making them ideal for applications requiring impact resistance and corrosion resistance. Carbon fiber composites provide superior strength-to-weight ratios and exceptional stiffness, enhancing performance in aerospace, automotive, and high-performance sporting goods where weight reduction is critical. Both materials exhibit long-term durability, but carbon fiber composites generally maintain structural integrity under fatigue and environmental stress better than glass fiber composites.

Weight Differences: Glass Fiber vs Carbon Fiber

Carbon fiber composites typically weigh about 40-50% less than glass fiber composites due to carbon's higher strength-to-weight ratio. Glass fiber composites have a density around 2.5 g/cm3, whereas carbon fiber composites range near 1.6 g/cm3, making carbon fiber preferred for lightweight applications. The significant weight savings of carbon fiber composites contribute to improved fuel efficiency and performance in aerospace and automotive industries.

Cost Analysis: Affordability and Investment

Glass fiber composites offer significantly lower material and manufacturing costs compared to carbon fiber composites, making them a more affordable option for large-scale production and budget-sensitive projects. Carbon fiber composites, while expensive due to raw material costs and energy-intensive processes, provide superior strength-to-weight ratios that justify the higher initial investment for performance-critical applications. Evaluating the total cost of ownership, including maintenance and lifecycle benefits, reveals that glass fiber composites excel in cost-efficiency, whereas carbon fiber composites deliver long-term value through enhanced durability and performance.

Applications in Industries

Glass fiber composites are widely used in automotive, construction, and marine industries due to their cost-effectiveness, corrosion resistance, and excellent impact strength. Carbon fiber composites are favored in aerospace, high-performance sports equipment, and luxury automotive sectors for their superior strength-to-weight ratio, stiffness, and fatigue resistance. Both materials enable lightweight, durable structures but are selected based on specific performance and budget requirements in industrial applications.

Environmental Impact and Sustainability

Glass fiber composites have a lower environmental impact during production due to less energy-intensive manufacturing processes compared to carbon fiber composites, which require high energy consumption for carbonization. The recyclability of glass fiber composites is generally more feasible, as they can be mechanically recycled or repurposed, while carbon fiber composites face challenges in recycling due to fiber degradation. Sustainable development favors glass fiber composites for their reduced carbon footprint and easier end-of-life handling, although carbon fiber composites offer superior strength-to-weight ratios that can contribute to long-term energy savings in applications such as aerospace and automotive industries.

Manufacturing Processes and Challenges

Glass fiber composites are typically manufactured using processes like hand lay-up, spray-up, and resin transfer molding, which are cost-effective but often result in higher weight and lower stiffness compared to carbon fiber composites. Carbon fiber composites demand more advanced techniques such as autoclave curing and filament winding, requiring precise temperature and pressure control to achieve optimal fiber alignment and matrix consolidation. Challenges in carbon fiber manufacturing include higher material costs, longer cycle times, and the necessity for specialized equipment to prevent defects like voids and delamination.

Choosing the Right Composite Material

Glass fiber composites offer enhanced impact resistance and cost-effectiveness, making them ideal for applications requiring durability and budget-friendly solutions. Carbon fiber composites provide superior strength-to-weight ratios and stiffness, preferred in aerospace and high-performance automotive industries. Selecting the right composite depends on specific performance criteria such as mechanical properties, environmental exposure, and cost constraints.

Glass fiber composite vs Carbon fiber composite Infographic

materialdif.com

materialdif.com