Out-of-autoclave curing techniques offer a cost-effective and flexible alternative to traditional autoclave curing by eliminating the need for high-pressure vessels while maintaining comparable mechanical properties in composite PET materials. These methods enhance manufacturing scalability and reduce energy consumption, making them ideal for large-scale or complex geometries where autoclave access is limited. Despite slightly longer cure cycles, out-of-autoclave processes maintain excellent fiber-matrix bonding and minimize void content, ensuring high-performance composite PET components.

Table of Comparison

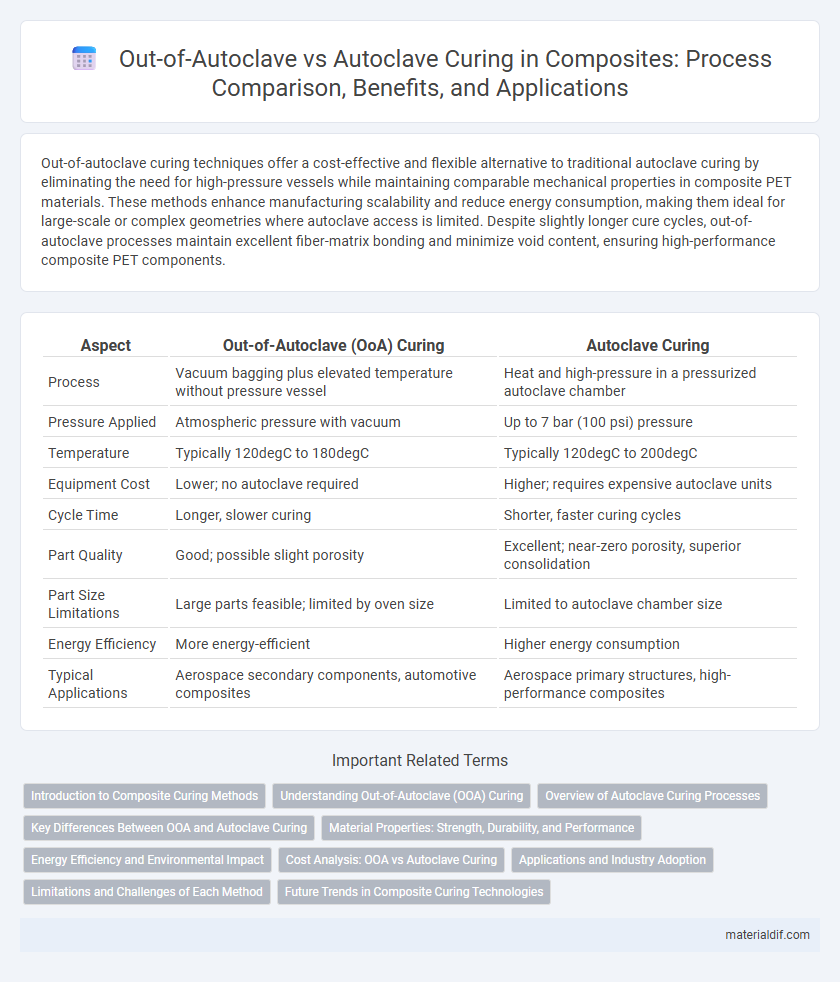

| Aspect | Out-of-Autoclave (OoA) Curing | Autoclave Curing |

|---|---|---|

| Process | Vacuum bagging plus elevated temperature without pressure vessel | Heat and high-pressure in a pressurized autoclave chamber |

| Pressure Applied | Atmospheric pressure with vacuum | Up to 7 bar (100 psi) pressure |

| Temperature | Typically 120degC to 180degC | Typically 120degC to 200degC |

| Equipment Cost | Lower; no autoclave required | Higher; requires expensive autoclave units |

| Cycle Time | Longer, slower curing | Shorter, faster curing cycles |

| Part Quality | Good; possible slight porosity | Excellent; near-zero porosity, superior consolidation |

| Part Size Limitations | Large parts feasible; limited by oven size | Limited to autoclave chamber size |

| Energy Efficiency | More energy-efficient | Higher energy consumption |

| Typical Applications | Aerospace secondary components, automotive composites | Aerospace primary structures, high-performance composites |

Introduction to Composite Curing Methods

Out-of-Autoclave (OOA) curing and autoclave curing are pivotal composite curing methods used to enhance mechanical properties and ensure void-free laminates in advanced aerospace and automotive applications. Autoclave curing utilizes high pressure and temperature in a sealed vessel, achieving superior consolidation and fiber-matrix bonding, whereas OOA curing relies on vacuum bagging and controlled heat cycles without external pressure, enabling cost-effective manufacturing and larger component sizes. Understanding the distinctions between OOA and autoclave curing is essential for selecting appropriate processing techniques based on performance requirements and production scalability.

Understanding Out-of-Autoclave (OOA) Curing

Out-of-Autoclave (OOA) curing processes enable the fabrication of composite materials at lower pressures, reducing equipment costs and increasing production scalability compared to traditional autoclave curing. OOA curing relies on advanced resin systems with optimized rheological properties to achieve void-free laminates and high mechanical performance without the need for high temperature and pressure environments. These processes offer significant advantages in aerospace and automotive industries by enabling large, complex composite structures with improved cost-efficiency and reduced cycle times.

Overview of Autoclave Curing Processes

Autoclave curing processes apply high pressure and temperature within a sealed chamber to enhance the consolidation and mechanical properties of composite materials. This method ensures uniform lamination, eliminates voids, and optimizes resin flow during curing, resulting in superior fiber-to-resin bonding. Autoclave curing is widely used in aerospace and high-performance applications where composite material integrity and strength are critical.

Key Differences Between OOA and Autoclave Curing

Out-of-autoclave (OOA) curing eliminates the need for high-pressure autoclaves by using vacuum bagging and controlled temperature cycles, enabling curing in standard ovens or even ambient conditions. Autoclave curing applies high temperature and pressure simultaneously, resulting in superior fiber consolidation and void reduction, ideal for high-performance aerospace composites. OOA processes offer cost savings and scalability but may yield slightly lower mechanical properties compared to the consistent and high-quality output of autoclave curing.

Material Properties: Strength, Durability, and Performance

Out-of-Autoclave (OOA) curing offers composites with comparable strength to autoclave-cured parts by minimizing void content through optimized resin systems and vacuum bagging techniques. Autoclave curing remains the benchmark for maximum fiber volume fraction and uniform consolidation, resulting in superior durability and mechanical performance critical in aerospace applications. Advances in OOA materials have narrowed the performance gap, making them suitable for complex geometries while reducing manufacturing costs and cycle times.

Energy Efficiency and Environmental Impact

Out-of-Autoclave (OoA) curing techniques reduce energy consumption by operating at lower temperatures and pressures compared to traditional autoclave curing, significantly lowering carbon emissions. OoA methods minimize reliance on large autoclave equipment, leading to decreased electricity usage and reduced operational costs. These advancements contribute to a smaller environmental footprint, making OoA curing a more sustainable option for composite manufacturing.

Cost Analysis: OOA vs Autoclave Curing

Out-of-Autoclave (OOA) curing significantly reduces manufacturing costs by eliminating the need for expensive autoclave equipment and high energy consumption, leading to lower operational expenses. OOA processes enable faster production cycles and reduced labor costs due to simpler tooling and less stringent process controls. Despite slightly higher material costs for specialized prepregs, the overall cost-effectiveness of OOA curing makes it a preferred choice in aerospace and automotive composite manufacturing.

Applications and Industry Adoption

Out-of-Autoclave (OOA) curing is increasingly favored in aerospace and automotive industries for manufacturing large or complex composite structures due to its lower cost and equipment requirements compared to traditional autoclave curing. Autoclave curing remains the industry standard for high-performance applications requiring superior mechanical properties and void reduction, such as in aerospace primary structures and high-end sporting goods. The adoption of OOA processes continues to grow as materials and process technologies improve, enabling wider use in secondary aircraft components and automotive parts where performance demands are moderate.

Limitations and Challenges of Each Method

Out-of-Autoclave (OoA) curing faces limitations such as longer cure times and potential for void formation due to lower pressure compared to autoclave curing, which can affect composite part quality and mechanical performance. Autoclave curing offers superior consolidation and fiber volume fraction control but involves high capital and operational costs, as well as size constraints due to autoclave chamber dimensions. Both methods present challenges in achieving consistent laminate thickness and resin distribution, demanding precise process control to optimize composite material properties.

Future Trends in Composite Curing Technologies

Out-of-autoclave (OOA) curing technologies are advancing rapidly, driven by demands for cost reduction, scalability, and improved environmental sustainability in composite manufacturing. Emerging trends include the integration of infrared and microwave curing methods, which offer faster cycle times and enhanced energy efficiency compared to traditional autoclave systems. Industry research increasingly focuses on hybrid curing processes combining the reliability of autoclaves with the flexibility of OOA techniques to optimize mechanical properties and production throughput.

Out-of-Autoclave Curing vs Autoclave Curing Infographic

materialdif.com

materialdif.com