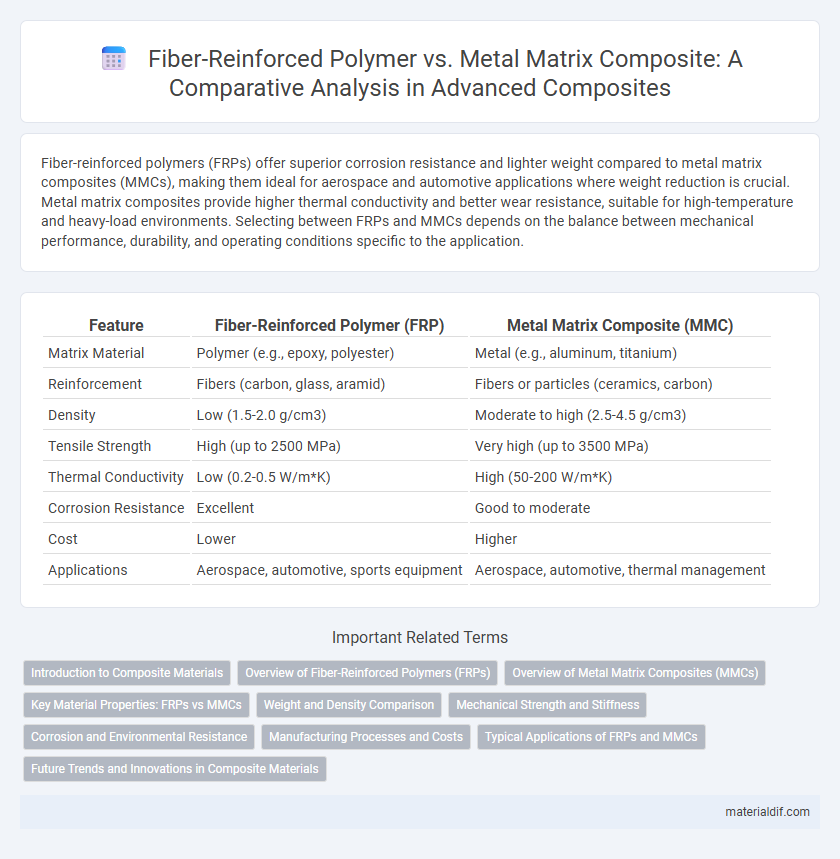

Fiber-reinforced polymers (FRPs) offer superior corrosion resistance and lighter weight compared to metal matrix composites (MMCs), making them ideal for aerospace and automotive applications where weight reduction is crucial. Metal matrix composites provide higher thermal conductivity and better wear resistance, suitable for high-temperature and heavy-load environments. Selecting between FRPs and MMCs depends on the balance between mechanical performance, durability, and operating conditions specific to the application.

Table of Comparison

| Feature | Fiber-Reinforced Polymer (FRP) | Metal Matrix Composite (MMC) |

|---|---|---|

| Matrix Material | Polymer (e.g., epoxy, polyester) | Metal (e.g., aluminum, titanium) |

| Reinforcement | Fibers (carbon, glass, aramid) | Fibers or particles (ceramics, carbon) |

| Density | Low (1.5-2.0 g/cm3) | Moderate to high (2.5-4.5 g/cm3) |

| Tensile Strength | High (up to 2500 MPa) | Very high (up to 3500 MPa) |

| Thermal Conductivity | Low (0.2-0.5 W/m*K) | High (50-200 W/m*K) |

| Corrosion Resistance | Excellent | Good to moderate |

| Cost | Lower | Higher |

| Applications | Aerospace, automotive, sports equipment | Aerospace, automotive, thermal management |

Introduction to Composite Materials

Fiber-reinforced polymers (FRPs) combine high-strength fibers like carbon or glass with polymer matrices, offering excellent strength-to-weight ratios and corrosion resistance. Metal matrix composites (MMCs) integrate ceramic or metal reinforcements within metal alloys, providing superior thermal stability and wear resistance for demanding structural applications. Both composites enhance mechanical properties beyond conventional materials, enabling advanced engineering solutions in aerospace, automotive, and industrial sectors.

Overview of Fiber-Reinforced Polymers (FRPs)

Fiber-Reinforced Polymers (FRPs) consist of high-strength fibers such as glass, carbon, or aramid embedded within a polymer matrix, offering exceptional strength-to-weight ratios and corrosion resistance. These composites are widely used in aerospace, automotive, and civil engineering due to their excellent fatigue performance and design flexibility. The polymer matrix in FRPs provides ductility and environmental resistance, while the fiber reinforcement primarily carries the mechanical loads.

Overview of Metal Matrix Composites (MMCs)

Metal Matrix Composites (MMCs) consist of a metal matrix, typically aluminum, magnesium, or titanium, reinforced with ceramic fibers or particles to enhance mechanical properties such as strength, stiffness, and thermal stability. Unlike Fiber-Reinforced Polymers (FRPs), MMCs exhibit superior temperature resistance, wear resistance, and dimensional stability, making them suitable for aerospace, automotive, and industrial applications. The combination of lightweight metals with high-performance reinforcements enables MMCs to achieve an optimal balance of weight reduction and enhanced load-bearing capacity.

Key Material Properties: FRPs vs MMCs

Fiber-reinforced polymers (FRPs) exhibit high strength-to-weight ratios and excellent corrosion resistance, making them ideal for lightweight applications with moderate thermal requirements. Metal matrix composites (MMCs) offer superior thermal conductivity, hardness, and wear resistance, supporting applications with high-temperature and heavy load demands. While FRPs excel in flexibility and ease of fabrication, MMCs provide enhanced mechanical stiffness and impact toughness due to their metal constituents.

Weight and Density Comparison

Fiber-reinforced polymers (FRPs) exhibit significantly lower density, typically around 1.5-2.0 g/cm3, compared to metal matrix composites (MMCs), which generally range from 2.5 to 3.5 g/cm3. This reduction in weight makes FRPs ideal for applications requiring high strength-to-weight ratios, such as aerospace and automotive industries. The lighter density of FRPs enhances fuel efficiency and performance, whereas MMCs offer superior thermal and wear resistance but at a higher weight penalty.

Mechanical Strength and Stiffness

Fiber-reinforced polymers (FRPs) exhibit high tensile strength and excellent stiffness-to-weight ratios, making them ideal for applications requiring lightweight durability. Metal matrix composites (MMCs) typically offer superior mechanical strength and higher stiffness compared to FRPs due to the reinforcing metal phase, enhancing load-bearing capabilities and thermal stability. Selection between FRPs and MMCs depends on specific performance criteria such as impact resistance, fatigue behavior, and environmental conditions.

Corrosion and Environmental Resistance

Fiber-reinforced polymer (FRP) composites exhibit superior corrosion resistance compared to metal matrix composites (MMCs) due to their non-metallic nature, which prevents oxidative degradation and reduces susceptibility to chemical attacks. MMCs, while offering enhanced mechanical properties, often require protective coatings to mitigate corrosion from environmental exposure such as moisture, salts, and acids. FRPs' inherent resistance to UV radiation, moisture ingress, and harsh chemicals makes them ideal for applications in aggressive environments where long-term durability is critical.

Manufacturing Processes and Costs

Fiber-reinforced polymers (FRPs) are typically manufactured using processes like hand lay-up, resin transfer molding, and filament winding, which offer lower tooling costs and greater design flexibility compared to metal matrix composites (MMCs). MMCs require more complex fabrication methods such as powder metallurgy, squeeze casting, and diffusion bonding, leading to higher production costs due to specialized equipment and longer cycle times. While FRPs boast cost-effective manufacturing and lower weight, MMCs provide enhanced mechanical properties at a premium cost, making the choice dependent on application requirements and budget constraints.

Typical Applications of FRPs and MMCs

Fiber-reinforced polymers (FRPs) are extensively used in aerospace structures, automotive components, and sporting goods due to their high strength-to-weight ratio and corrosion resistance. Metal matrix composites (MMCs) find typical applications in aerospace engine parts, high-performance automotive brakes, and electronic packaging, benefiting from their superior thermal conductivity and mechanical properties under extreme conditions. Both materials enable enhanced performance in industries demanding lightweight and durable solutions.

Future Trends and Innovations in Composite Materials

Fiber-reinforced polymers (FRPs) continue to dominate lightweight structural applications due to their high strength-to-weight ratio and corrosion resistance, while metal matrix composites (MMCs) are gaining traction for their superior thermal conductivity and wear resistance in aerospace and automotive sectors. Future trends emphasize hybrid composites combining FRPs and MMCs to optimize mechanical properties and multifunctionality, alongside advancements in nanomaterial integration such as graphene and carbon nanotubes to enhance durability and performance. Innovations in additive manufacturing enable complex geometries and tailored performance, accelerating the deployment of next-generation composites with improved recyclability and sustainability metrics.

Fiber-reinforced polymer vs Metal matrix composite Infographic

materialdif.com

materialdif.com