Prepreg composites offer superior fiber-matrix bonding due to pre-impregnated resin, resulting in higher strength and consistency compared to wet lay-up methods. Wet lay-up involves manually applying resin to dry fibers, which can introduce voids and variability in laminate quality. While prepreg requires refrigerated storage and controlled curing, it delivers better mechanical properties and repeatability for high-performance composite applications.

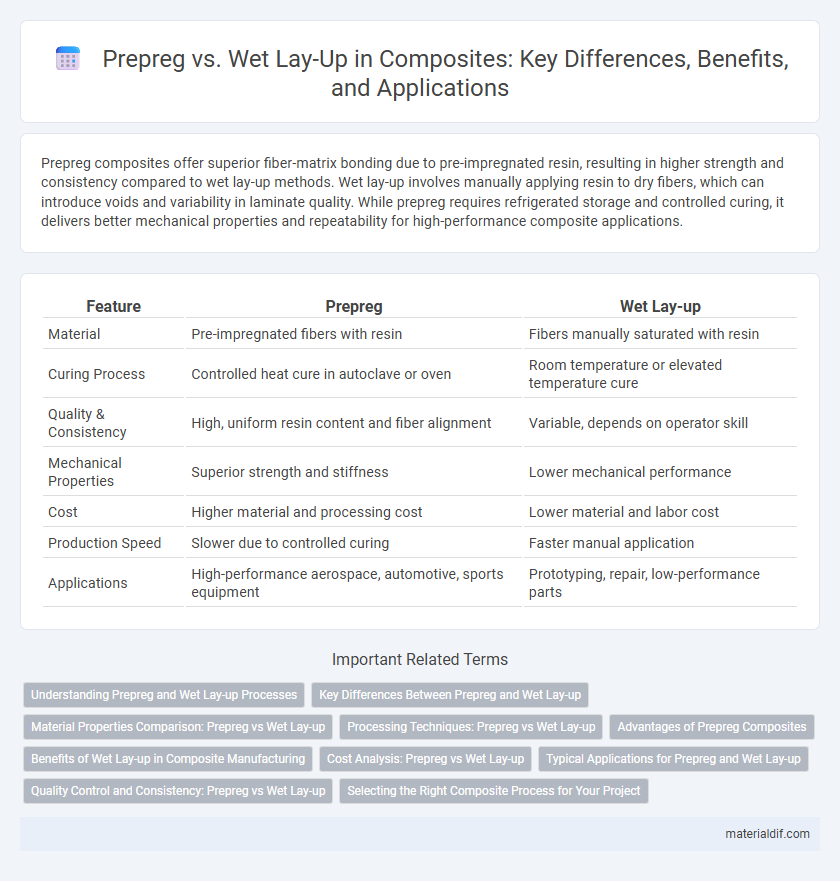

Table of Comparison

| Feature | Prepreg | Wet Lay-up |

|---|---|---|

| Material | Pre-impregnated fibers with resin | Fibers manually saturated with resin |

| Curing Process | Controlled heat cure in autoclave or oven | Room temperature or elevated temperature cure |

| Quality & Consistency | High, uniform resin content and fiber alignment | Variable, depends on operator skill |

| Mechanical Properties | Superior strength and stiffness | Lower mechanical performance |

| Cost | Higher material and processing cost | Lower material and labor cost |

| Production Speed | Slower due to controlled curing | Faster manual application |

| Applications | High-performance aerospace, automotive, sports equipment | Prototyping, repair, low-performance parts |

Understanding Prepreg and Wet Lay-up Processes

Prepreg involves the use of pre-impregnated fibers with a precise resin-to-fiber ratio, ensuring consistent quality and enhanced mechanical properties in composite manufacturing. Wet lay-up requires manually applying resin to dry fibers on the mold, offering flexibility but with higher variability in resin content and laminate thickness. Understanding these differences is crucial for selecting the appropriate process based on performance requirements and production scale.

Key Differences Between Prepreg and Wet Lay-up

Prepreg materials consist of fiber reinforcement pre-impregnated with a controlled amount of resin, offering precise resin-to-fiber ratios and enhanced mechanical properties, while wet lay-up involves manually applying resin to dry fibers, resulting in variability in resin content and potential for lower strength. Prepreg requires refrigeration before curing and typically cures under heat and pressure in an autoclave or oven, whereas wet lay-up cures at room temperature without specialized equipment. The controlled manufacturing process of prepreg leads to superior consistency, higher fiber volume fractions, and improved composite performance compared to the more flexible but less reproducible wet lay-up method.

Material Properties Comparison: Prepreg vs Wet Lay-up

Prepreg materials offer superior fiber-resin ratio control and enhanced mechanical properties such as higher tensile strength and improved fatigue resistance compared to wet lay-up, which relies on manual resin application leading to variable fiber wetting and potential voids. Prepregs provide consistent curing conditions and better resin distribution, resulting in laminates with increased interlaminar shear strength and reduced void content. Wet lay-up processes, while more cost-effective and flexible, typically yield composites with lower structural performance and less repeatability in quality.

Processing Techniques: Prepreg vs Wet Lay-up

Prepreg processing involves using pre-impregnated fibers with a precise resin-to-fiber ratio, allowing for consistent quality and reduced void content through controlled curing cycles in autoclaves. Wet lay-up requires manual application of resin onto dry fibers, which can lead to variable resin content and potential defects due to less controlled curing environments. Prepreg techniques enhance mechanical properties and repeatability, making them ideal for high-performance composite structures, whereas wet lay-up offers cost-effectiveness and flexibility suitable for simpler applications.

Advantages of Prepreg Composites

Prepreg composites offer superior fiber-matrix uniformity and enhanced mechanical properties compared to wet lay-up processes, resulting in higher strength-to-weight ratios and improved structural performance. The controlled resin content in prepregs reduces void formation and ensures consistent curing, leading to better durability and fatigue resistance. Prepreg materials also facilitate precise thickness control and repeatable quality, making them ideal for aerospace and high-performance automotive applications.

Benefits of Wet Lay-up in Composite Manufacturing

Wet lay-up in composite manufacturing offers superior flexibility by allowing on-site fabrication and repair, reducing lead times and tooling costs. This method enables thorough wetting of fibers with resin, resulting in strong fiber-resin adhesion that enhances structural integrity. Wet lay-up also supports complex shapes and large structures without expensive autoclaves, making it cost-effective for low-volume or custom composite parts.

Cost Analysis: Prepreg vs Wet Lay-up

Prepreg materials generally incur higher upfront costs due to specialized manufacturing and storage requirements, but they offer superior consistency and lower labor expenses during composite fabrication. Wet lay-up techniques feature lower material costs and require simpler storage conditions but often lead to increased labor time and variability in quality, which can raise overall production expenses. Evaluating total project costs involves balancing prepreg's premium price against wet lay-up's flexible yet labor-intensive process for optimized budget management.

Typical Applications for Prepreg and Wet Lay-up

Prepreg materials are commonly used in aerospace, automotive, and high-performance sporting goods due to their precise fiber-resin ratio and superior mechanical properties. Wet lay-up techniques are typically employed in marine, wind turbine blades, and civil infrastructure applications, offering cost-effective and flexible manufacturing for large or complex shapes. Choosing between prepreg and wet lay-up depends on production volume, performance requirements, and environmental conditions of the end-use application.

Quality Control and Consistency: Prepreg vs Wet Lay-up

Prepreg composites provide superior quality control and consistency due to their controlled resin content and factory-cured process, reducing variability and defects common in wet lay-up methods. Wet lay-up relies on manual resin application, leading to inconsistent fiber-to-resin ratios and increased potential for voids and weak spots. This inherent precision in prepreg materials ensures enhanced mechanical properties and repeatability in high-performance composite manufacturing.

Selecting the Right Composite Process for Your Project

Selecting the right composite process depends on project requirements such as mechanical properties, production volume, and cost constraints. Prepreg offers superior fiber-resin ratio control and consistent quality, ideal for high-performance aerospace and automotive parts, while wet lay-up provides flexibility and lower upfront costs suitable for smaller production runs and prototypes. Consider factors like curing methods, material handling, and desired structural integrity to determine whether prepreg's pre-impregnated fibers or wet lay-up's manual resin application best align with your composite manufacturing goals.

Prepreg vs Wet Lay-up Infographic

materialdif.com

materialdif.com