Thermoset composites offer superior heat resistance and structural rigidity due to their cross-linked polymer matrix, making them ideal for high-temperature and high-strength applications. Thermoplastic composites provide enhanced impact resistance, recyclability, and shorter manufacturing cycles thanks to their thermally reversible polymer chains. Selecting between the two depends on factors such as durability, recyclability, manufacturing speed, and operating environment requirements.

Table of Comparison

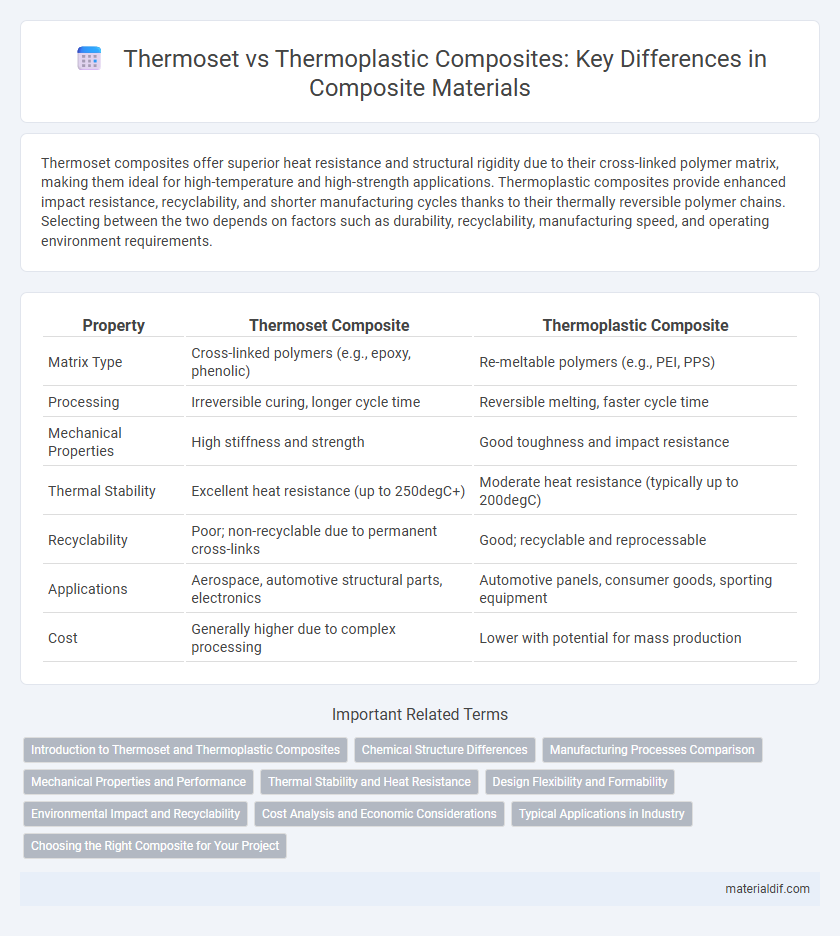

| Property | Thermoset Composite | Thermoplastic Composite |

|---|---|---|

| Matrix Type | Cross-linked polymers (e.g., epoxy, phenolic) | Re-meltable polymers (e.g., PEI, PPS) |

| Processing | Irreversible curing, longer cycle time | Reversible melting, faster cycle time |

| Mechanical Properties | High stiffness and strength | Good toughness and impact resistance |

| Thermal Stability | Excellent heat resistance (up to 250degC+) | Moderate heat resistance (typically up to 200degC) |

| Recyclability | Poor; non-recyclable due to permanent cross-links | Good; recyclable and reprocessable |

| Applications | Aerospace, automotive structural parts, electronics | Automotive panels, consumer goods, sporting equipment |

| Cost | Generally higher due to complex processing | Lower with potential for mass production |

Introduction to Thermoset and Thermoplastic Composites

Thermoset composites consist of polymer matrices that undergo irreversible chemical curing, resulting in a rigid and heat-resistant structure ideal for high-performance applications. In contrast, thermoplastic composites utilize polymers that can be repeatedly melted and reshaped, offering enhanced recyclability and impact resistance. Both materials serve critical roles in aerospace, automotive, and construction industries, with thermosets favored for structural strength and thermoplastics preferred for flexibility and rapid manufacturing.

Chemical Structure Differences

Thermoset composites consist of cross-linked polymer chains forming a rigid, three-dimensional network through irreversible chemical bonds, resulting in high heat resistance and structural stability. Thermoplastic composites are made of linear or branched polymers with physical entanglements rather than covalent cross-links, allowing them to soften upon reheating and enabling recyclability. The chemical structure of thermosets provides enhanced dimensional stability and chemical resistance, whereas thermoplastics offer greater toughness and impact resistance due to their molecular mobility.

Manufacturing Processes Comparison

Thermoset composites are manufactured through curing processes involving chemical reactions, typically using methods like resin transfer molding (RTM) or compression molding, which create a rigid, cross-linked polymer matrix. Thermoplastic composites are processed using melting and solidification techniques such as injection molding or hot pressing, allowing for faster production cycles and recyclability due to their reversible thermoplastic matrix. The choice between thermoset and thermoplastic composites depends on factors such as production volume, cycle time, mechanical performance, and potential for material reuse.

Mechanical Properties and Performance

Thermoset composites exhibit superior thermal stability and chemical resistance due to their cross-linked polymer matrix, resulting in higher stiffness and better dimensional stability under load. Thermoplastic composites offer enhanced impact resistance, toughness, and the ability to be reshaped and recycled, making them more adaptable for dynamic and repetitive mechanical stresses. The choice between thermoset and thermoplastic composites depends on specific performance requirements such as fatigue resistance, fracture toughness, and manufacturing efficiency in aerospace, automotive, and construction industries.

Thermal Stability and Heat Resistance

Thermoset composites exhibit superior thermal stability and heat resistance due to their cross-linked polymer matrix, enabling them to maintain structural integrity at elevated temperatures above 200degC. In contrast, thermoplastic composites soften and can deform when exposed to high heat, typically above 150-170degC, because of their linear or branched polymer chains without chemical cross-linking. This makes thermoset composites ideal for high-temperature applications in aerospace and automotive industries where thermal performance is critical.

Design Flexibility and Formability

Thermoset composites offer excellent chemical resistance and thermal stability but exhibit limited design flexibility due to their irreversible curing process, which restricts reshaping once set. In contrast, thermoplastic composites provide superior formability and design adaptability, benefiting from their ability to be reheated and reshaped multiple times without degrading material properties. This reversible melting behavior allows for complex geometries and easier repairs, making thermoplastic composites ideal for applications requiring intricate designs and rapid prototyping.

Environmental Impact and Recyclability

Thermoset composites exhibit superior mechanical properties but present significant environmental challenges due to their non-recyclable cross-linked polymer matrices that hinder reuse and contribute to landfill waste. Thermoplastic composites offer enhanced recyclability through remelting and reshaping processes, reducing environmental impact by enabling material recovery and circular lifecycle management. Lifecycle assessments demonstrate thermoplastic composites generate lower greenhouse gas emissions and energy consumption during recycling compared to thermoset composites, driving sustainable composite material selection.

Cost Analysis and Economic Considerations

Thermoset composites generally have lower raw material costs but incur higher processing expenses due to longer curing times and specialized equipment, leading to increased labor costs. Thermoplastic composites offer faster production cycles and recyclability, which reduce long-term manufacturing and disposal expenses, making them economically favorable for high-volume applications. Cost analysis must weigh initial investment against lifecycle savings, where thermoplastics excel in automotive sectors, while thermosets remain competitive in aerospace due to superior thermal and mechanical properties.

Typical Applications in Industry

Thermoset composites are extensively used in aerospace and automotive industries for structural components due to their superior thermal stability and chemical resistance. Thermoplastic composites find typical applications in manufacturing consumer goods and medical devices, offering advantages in impact resistance and recyclability. Both materials serve critical roles in industrial tooling and electrical insulation, tailored to specific performance requirements.

Choosing the Right Composite for Your Project

Thermoset composites offer superior thermal stability and chemical resistance, making them ideal for high-temperature and load-bearing applications. Thermoplastic composites provide greater impact resistance and easier recyclability, suitable for projects requiring repeated stress and environmental sustainability. Selecting the right composite depends on balancing mechanical performance, processing methods, and end-use conditions to optimize cost-efficiency and durability.

Thermoset Composite vs Thermoplastic Composite Infographic

materialdif.com

materialdif.com