Unidirectional composites feature fibers aligned in a single direction, providing maximum strength and stiffness along that axis, ideal for applications requiring high tensile performance. Bidirectional composites incorporate fibers woven or layered at two angles, enhancing strength, stiffness, and resistance to deformation in multiple directions. Choosing between unidirectional and bidirectional composites depends on load requirements and structural demands in engineering designs.

Table of Comparison

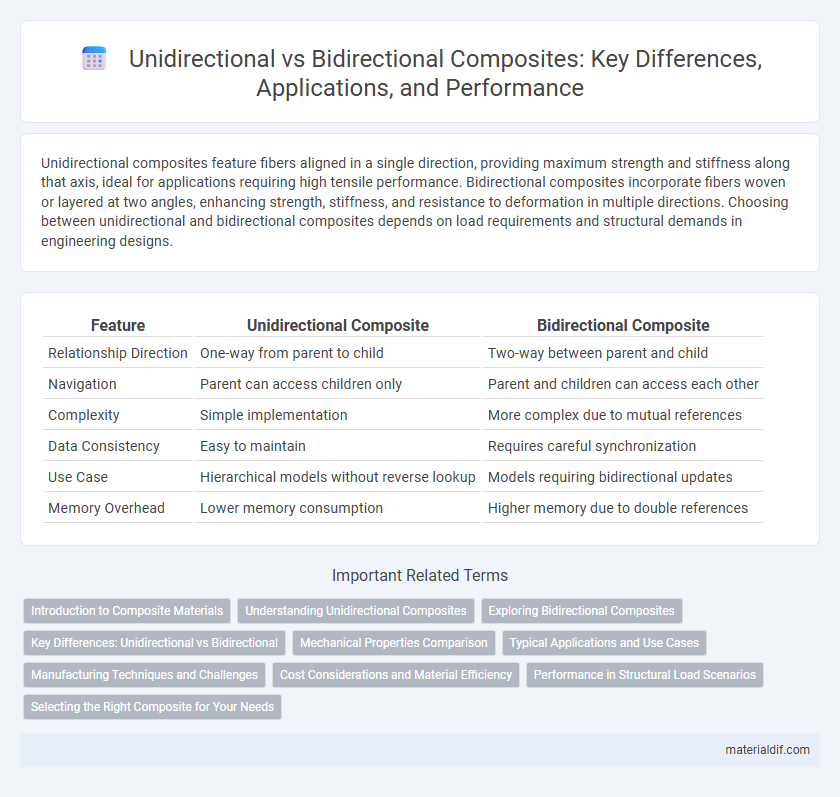

| Feature | Unidirectional Composite | Bidirectional Composite |

|---|---|---|

| Relationship Direction | One-way from parent to child | Two-way between parent and child |

| Navigation | Parent can access children only | Parent and children can access each other |

| Complexity | Simple implementation | More complex due to mutual references |

| Data Consistency | Easy to maintain | Requires careful synchronization |

| Use Case | Hierarchical models without reverse lookup | Models requiring bidirectional updates |

| Memory Overhead | Lower memory consumption | Higher memory due to double references |

Introduction to Composite Materials

Composite materials combine two or more distinct phases to achieve superior mechanical properties. Unidirectional composites consist of fibers aligned in a single direction, offering high strength and stiffness along that axis. Bidirectional composites feature fibers woven or arranged in two directions, providing enhanced strength and stability across multiple axes.

Understanding Unidirectional Composites

Unidirectional composites consist of fibers aligned in a single direction, providing high strength and stiffness primarily along that axis. This alignment optimizes load transfer and resistance to tension and bending in specific structural applications, making them ideal for components subjected to uniaxial stresses. Understanding fiber orientation, matrix properties, and interface bonding is critical for maximizing mechanical performance in unidirectional composite materials.

Exploring Bidirectional Composites

Bidirectional composites enable load transfer in two directions, enhancing mechanical properties such as tensile strength and stiffness compared to unidirectional composites, which primarily carry load along a single axis. These materials offer improved impact resistance and dimensional stability, making them ideal for complex structural applications in aerospace and automotive industries. Understanding the fiber orientation and matrix interaction in bidirectional composites is crucial for optimizing performance and durability.

Key Differences: Unidirectional vs Bidirectional

Unidirectional composite relationships allow navigation from the parent object to its child objects only, simplifying the data flow and reducing complexity in object references. Bidirectional composite relationships enable navigation in both directions, allowing parent objects to access child objects and vice versa, which facilitates dynamic object interactions but increases memory usage and potential circular dependencies. Key differences include data accessibility, reference management, and complexity of implementation, with unidirectional composites favoring simplicity and bidirectional composites supporting comprehensive object connectivity.

Mechanical Properties Comparison

Unidirectional composites exhibit superior tensile strength and stiffness along the fiber direction due to aligned reinforcement, enhancing load transfer efficiency. Bidirectional composites provide improved in-plane shear strength and balanced mechanical properties, distributing stresses more evenly across multiple directions. The choice between unidirectional and bidirectional composites depends on application-specific load requirements and desired performance characteristics.

Typical Applications and Use Cases

Unidirectional composites are commonly used in aerospace and automotive industries where high strength and stiffness are required along one primary load direction, such as aircraft wings and automotive drive shafts. Bidirectional composites find typical applications in marine structures, wind turbine blades, and sporting goods, providing strength and durability across multiple directions due to their woven fiber architecture. Selecting between unidirectional and bidirectional composites depends on load distribution patterns and performance criteria specific to each engineering application.

Manufacturing Techniques and Challenges

Unidirectional composites involve fibers aligned in a single direction, optimizing strength and stiffness along that axis but posing challenges in handling and layup accuracy during manufacturing. Bidirectional composites integrate fibers in two perpendicular directions, offering balanced mechanical properties and improved damage resistance, yet require more complex fabrication processes like weaving or braiding. Manufacturing challenges for both include ensuring proper resin impregnation, avoiding voids, and managing cure cycles to achieve desired performance criteria.

Cost Considerations and Material Efficiency

Unidirectional composites often present lower manufacturing costs due to simpler layup processes and reduced labor requirements compared to bidirectional composites, which require intricate fiber orientations increasing production complexity. Material efficiency in unidirectional composites is optimized for load-bearing applications in a single direction, minimizing waste, whereas bidirectional composites offer enhanced strength in multiple directions but may lead to higher material usage and costs. Selecting between unidirectional and bidirectional composites depends on balancing cost constraints against the desired mechanical performance and material utilization efficiency.

Performance in Structural Load Scenarios

Unidirectional composites deliver superior performance in structural load scenarios requiring high tensile strength along a single axis, optimizing stiffness and load-bearing capacity with enhanced fiber alignment. Bidirectional composites provide balanced mechanical properties by distributing loads more evenly across two perpendicular directions, improving resistance to shear and multidirectional forces. In high-load applications, unidirectional composites excel under axial tension, while bidirectional composites offer better durability under complex stress states, influencing material selection based on specific structural demands.

Selecting the Right Composite for Your Needs

Selecting the right composite depends on understanding the difference between unidirectional and bidirectional composites, where unidirectional composites provide strength primarily in one direction due to aligned fibers, making them ideal for load-bearing applications with directional stress. Bidirectional composites offer enhanced strength and stability in two perpendicular directions thanks to woven or cross-laid fibers, suitable for applications requiring multidirectional load resistance. Evaluating the specific mechanical requirements and environmental conditions of your project ensures optimal composite selection for durability and performance.

Unidirectional vs Bidirectional Infographic

materialdif.com

materialdif.com