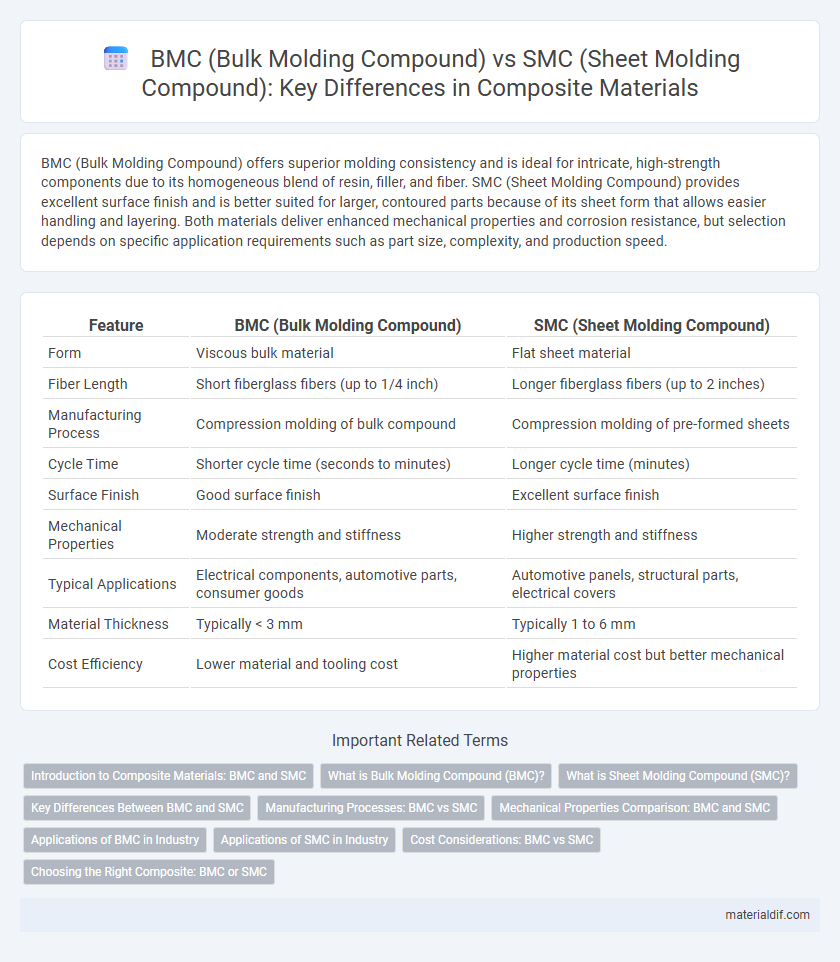

BMC (Bulk Molding Compound) offers superior molding consistency and is ideal for intricate, high-strength components due to its homogeneous blend of resin, filler, and fiber. SMC (Sheet Molding Compound) provides excellent surface finish and is better suited for larger, contoured parts because of its sheet form that allows easier handling and layering. Both materials deliver enhanced mechanical properties and corrosion resistance, but selection depends on specific application requirements such as part size, complexity, and production speed.

Table of Comparison

| Feature | BMC (Bulk Molding Compound) | SMC (Sheet Molding Compound) |

|---|---|---|

| Form | Viscous bulk material | Flat sheet material |

| Fiber Length | Short fiberglass fibers (up to 1/4 inch) | Longer fiberglass fibers (up to 2 inches) |

| Manufacturing Process | Compression molding of bulk compound | Compression molding of pre-formed sheets |

| Cycle Time | Shorter cycle time (seconds to minutes) | Longer cycle time (minutes) |

| Surface Finish | Good surface finish | Excellent surface finish |

| Mechanical Properties | Moderate strength and stiffness | Higher strength and stiffness |

| Typical Applications | Electrical components, automotive parts, consumer goods | Automotive panels, structural parts, electrical covers |

| Material Thickness | Typically < 3 mm | Typically 1 to 6 mm |

| Cost Efficiency | Lower material and tooling cost | Higher material cost but better mechanical properties |

Introduction to Composite Materials: BMC and SMC

Bulk Molding Compound (BMC) and Sheet Molding Compound (SMC) are widely used composite materials consisting of thermosetting resins reinforced with glass fibers, designed for high-volume manufacturing. BMC features a dough-like consistency ideal for injection molding intricate components, while SMC is a fiber-reinforced sheet optimized for compression molding large, flat or contoured parts. Both materials offer excellent mechanical strength, corrosion resistance, and lightweight properties, making them essential in automotive, electrical, and aerospace industries.

What is Bulk Molding Compound (BMC)?

Bulk Molding Compound (BMC) is a ready-to-mold composite material consisting of thermosetting resins, reinforcing fibers such as glass, and fillers that provide enhanced mechanical properties and electrical insulation. BMC is characterized by its moldable bulk form, allowing for complex shapes and high-volume production with consistent material distribution and superior surface finish. This composite is widely used in automotive, electrical, and industrial applications due to its excellent heat resistance, dimensional stability, and corrosion resistance.

What is Sheet Molding Compound (SMC)?

Sheet Molding Compound (SMC) is a fiber-reinforced composite material consisting of glass fibers, resin, fillers, and catalysts molded into thin sheets for use in compression molding processes. It offers high strength-to-weight ratios, excellent surface finish, and consistent thickness, making it ideal for automotive panels, electrical components, and structural parts. SMC provides superior mechanical properties and corrosion resistance compared to Bulk Molding Compound (BMC), particularly suited for larger, more complex-shaped parts with fine surface detail.

Key Differences Between BMC and SMC

Bulk Molding Compound (BMC) consists of a highly viscous mixture of resin, filler, and chopped fibers that is molded under heat and pressure, whereas Sheet Molding Compound (SMC) is a fiberglass-reinforced polyester material formed into flat sheets allowing for larger and more complex parts. BMC typically offers better electrical properties and finer surface finish, making it ideal for intricate components, while SMC provides superior mechanical strength and dimensional stability suited for structural automotive panels. The molding process for BMC involves compression molding with shorter cycle times, contrasting with the longer cycle but more versatile out-of-autoclave shaping capabilities of SMC.

Manufacturing Processes: BMC vs SMC

Bulk Molding Compound (BMC) manufacturing involves a high-pressure molding process where the material, a blend of resin, fillers, and chopped glass fibers, is injected into a heated mold to form complex, small to medium-sized parts. Sheet Molding Compound (SMC) utilizes a continuous sheet of resin combined with chopped fibers, which is cut, placed into a mold, and compressed under heat and pressure to create larger, intricate components with excellent surface finish and dimensional stability. The BMC process offers faster cycle times suited for high-volume production, whereas SMC allows for thicker, more mechanically robust parts, catering to applications requiring both strength and aesthetic quality.

Mechanical Properties Comparison: BMC and SMC

BMC (Bulk Molding Compound) exhibits higher tensile strength and better impact resistance compared to SMC (Sheet Molding Compound), making it ideal for complex, detailed components requiring durability. SMC offers superior dimensional stability and improved surface finish due to its sheet form and compressive molding process, enhancing performance in larger, flat parts. Both materials balance stiffness and elasticity differently, with BMC favoring toughness and SMC excelling in consistent structural integrity.

Applications of BMC in Industry

Bulk Molding Compound (BMC) finds extensive application in automotive components such as electrical housings, structural parts, and connectors due to its excellent electrical insulation and high tensile strength. In the electrical industry, BMC is widely used for switchgear, circuit breaker cases, and fuse components, benefiting from its heat resistance and flame retardant properties. Medical devices and appliance housings also leverage BMC for precision molding and dimensional stability under thermal stress.

Applications of SMC in Industry

SMC (Sheet Molding Compound) excels in automotive manufacturing for producing complex, lightweight, and high-strength components such as body panels and structural parts due to its excellent dimensional stability and surface finish. It is widely used in electrical industries for manufacturing enclosures and insulation materials, leveraging its high dielectric strength and thermal resistance. In construction, SMC finds applications in durable roofing materials, wall panels, and molded parts resistant to corrosion and environmental degradation.

Cost Considerations: BMC vs SMC

Bulk Molding Compound (BMC) generally offers lower material costs compared to Sheet Molding Compound (SMC) due to its simplified processing and reduced labor requirements. SMC incurs higher costs driven by its more complex manufacturing process and superior surface finish quality, which demands more precise tooling and longer curing times. For large-scale production where cost-efficiency is critical, BMC is often preferred, whereas SMC is chosen for applications requiring enhanced aesthetics and mechanical properties despite the higher expense.

Choosing the Right Composite: BMC or SMC

BMC (Bulk Molding Compound) offers superior flow characteristics and is ideal for complex, detailed molded parts with intricate geometries, while SMC (Sheet Molding Compound) excels in producing larger, flat, or moderately contoured components due to its uniform thickness and fiber alignment. Material selection depends on factors such as part size, surface finish requirements, and mechanical performance, with BMC providing better electrical insulation and SMC delivering enhanced impact resistance and structural integrity. Evaluating production volume and mold design complexity ensures optimal cost efficiency and part quality when choosing between BMC and SMC composites.

BMC (Bulk Molding Compound) vs SMC (Sheet Molding Compound) Infographic

materialdif.com

materialdif.com