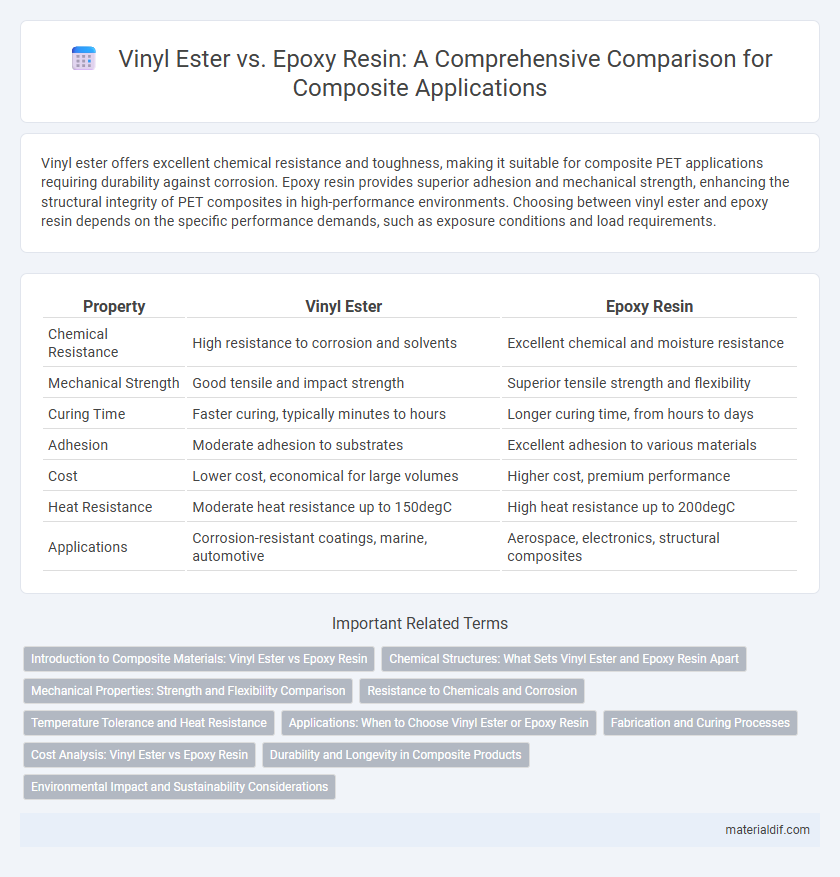

Vinyl ester offers excellent chemical resistance and toughness, making it suitable for composite PET applications requiring durability against corrosion. Epoxy resin provides superior adhesion and mechanical strength, enhancing the structural integrity of PET composites in high-performance environments. Choosing between vinyl ester and epoxy resin depends on the specific performance demands, such as exposure conditions and load requirements.

Table of Comparison

| Property | Vinyl Ester | Epoxy Resin |

|---|---|---|

| Chemical Resistance | High resistance to corrosion and solvents | Excellent chemical and moisture resistance |

| Mechanical Strength | Good tensile and impact strength | Superior tensile strength and flexibility |

| Curing Time | Faster curing, typically minutes to hours | Longer curing time, from hours to days |

| Adhesion | Moderate adhesion to substrates | Excellent adhesion to various materials |

| Cost | Lower cost, economical for large volumes | Higher cost, premium performance |

| Heat Resistance | Moderate heat resistance up to 150degC | High heat resistance up to 200degC |

| Applications | Corrosion-resistant coatings, marine, automotive | Aerospace, electronics, structural composites |

Introduction to Composite Materials: Vinyl Ester vs Epoxy Resin

Vinyl ester and epoxy resin are two primary matrix materials used in composite manufacturing, valued for their distinct chemical structures and performance properties. Vinyl ester offers excellent corrosion resistance and good mechanical strength, making it suitable for marine and chemical applications, while epoxy resin provides superior adhesion, higher tensile strength, and better electrical insulation, often preferred in aerospace and automotive industries. Both resins contribute to the durability and versatility of composite materials, influencing factors like moisture resistance, curing time, and overall composite lifespan.

Chemical Structures: What Sets Vinyl Ester and Epoxy Resin Apart

Vinyl ester and epoxy resin differ significantly in their chemical structures, with vinyl ester containing ester groups formed by the reaction of epoxy resin with unsaturated carboxylic acids, resulting in a more flexible polymer backbone. Epoxy resin features reactive epoxide rings that cure into a highly cross-linked, rigid thermoset network, offering superior mechanical strength and chemical resistance. These structural distinctions influence their performance, processing methods, and application suitability in composite materials.

Mechanical Properties: Strength and Flexibility Comparison

Vinyl ester resins exhibit excellent chemical resistance and good tensile strength, making them suitable for corrosion-resistant composite applications, but generally have lower flexural strength and elongation compared to epoxy resins. Epoxy resins provide superior mechanical properties, including higher tensile strength, improved flexural modulus, and greater flexibility due to better cross-linking density, which enhances durability under stress and impact. The choice between vinyl ester and epoxy resin depends on the specific mechanical demands of the composite structure, where epoxy is preferred for high-strength and high-flexibility requirements.

Resistance to Chemicals and Corrosion

Vinyl ester resin offers superior resistance to chemicals and corrosion compared to epoxy resin, making it ideal for use in harsh environments such as marine and chemical processing industries. Its molecular structure provides excellent resistance to acids, alkalis, and solvents, enhancing the durability and lifespan of composite materials. Epoxy resin, while strong and mechanically robust, generally exhibits lower chemical resistance, which may limit its application in highly corrosive conditions.

Temperature Tolerance and Heat Resistance

Vinyl ester resins exhibit superior temperature tolerance with thermal stability typically up to 150-200degC, making them ideal for high-heat composite applications. Epoxy resins generally have lower heat resistance, often stable only up to 120-150degC, but provide excellent mechanical strength and chemical resistance. Selecting vinyl ester over epoxy is advantageous when elevated temperature performance and enhanced heat resistance are critical for composite durability.

Applications: When to Choose Vinyl Ester or Epoxy Resin

Vinyl ester resin excels in corrosion-resistant applications such as chemical storage tanks and marine environments due to its superior resistance to acids and alkalis. Epoxy resin is preferred for high-strength structural composites and adhesive bonding in aerospace, automotive, and wind turbine blades where mechanical performance and durability are critical. Selecting between vinyl ester and epoxy resin depends on specific environmental exposure and mechanical load requirements, balancing chemical resistance with structural integrity.

Fabrication and Curing Processes

Vinyl ester resins cure rapidly through a free-radical polymerization process initiated by peroxides, allowing faster fabrication with lower exotherm compared to epoxy resins. Epoxy resins require a longer, more controlled curing process involving amine hardeners or anhydrides, enabling superior control of mechanical properties and reducing residual stresses. Fabrication with vinyl esters often suits hand lay-up and spray-up methods, while epoxies are preferred for precise molding and applications demanding higher structural integrity.

Cost Analysis: Vinyl Ester vs Epoxy Resin

Vinyl ester resin generally offers a lower initial material cost compared to epoxy resin, making it a more budget-friendly option for composite manufacturing. Epoxy resin, while more expensive, provides superior mechanical properties and chemical resistance, which can reduce long-term maintenance and replacement costs. Evaluating total cost of ownership, including performance and durability, is essential in deciding between vinyl ester and epoxy resin for specific applications.

Durability and Longevity in Composite Products

Vinyl ester offers superior resistance to water and chemical corrosion, making it highly durable for marine and chemical storage composite products. Epoxy resin exhibits exceptional mechanical strength and delivers outstanding adhesion, contributing to increased longevity in aerospace and automotive composites. Both resins enhance composite durability, but epoxy generally provides longer service life under high-stress conditions.

Environmental Impact and Sustainability Considerations

Vinyl ester resins generally exhibit lower environmental persistence compared to epoxy resins, as they degrade more readily under certain conditions, reducing long-term ecological impact. Epoxy resins, though highly durable, often involve hazardous chemicals during production, leading to increased carbon footprint and challenges in recycling processes. Sustainable alternatives are being developed in both categories, emphasizing bio-based feedstocks and improved end-of-life disposal to mitigate environmental concerns in composite manufacturing.

Vinyl Ester vs Epoxy Resin Infographic

materialdif.com

materialdif.com