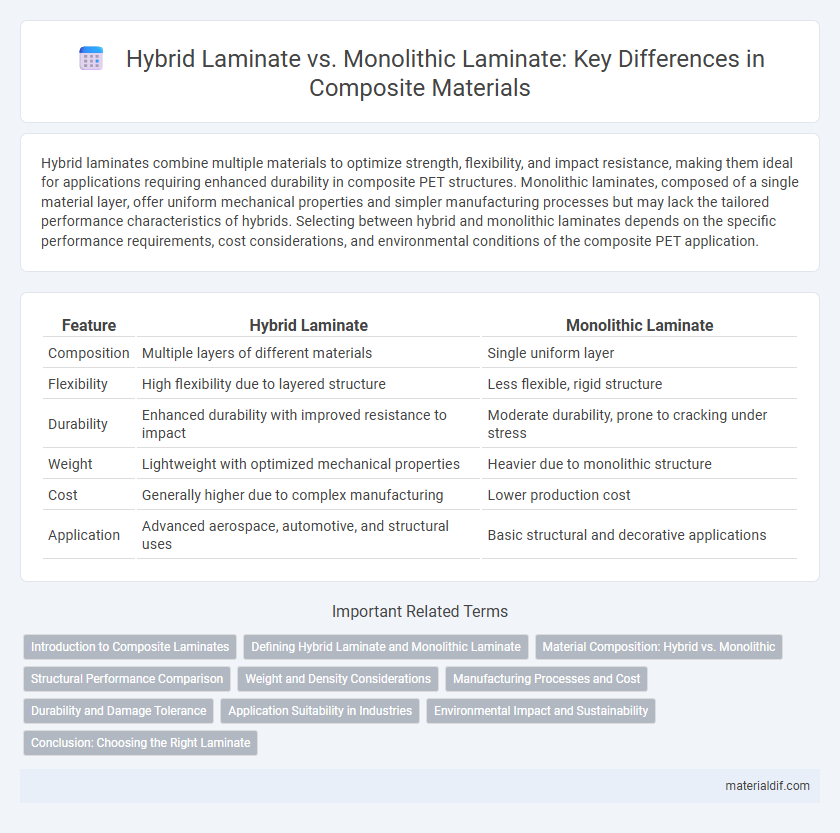

Hybrid laminates combine multiple materials to optimize strength, flexibility, and impact resistance, making them ideal for applications requiring enhanced durability in composite PET structures. Monolithic laminates, composed of a single material layer, offer uniform mechanical properties and simpler manufacturing processes but may lack the tailored performance characteristics of hybrids. Selecting between hybrid and monolithic laminates depends on the specific performance requirements, cost considerations, and environmental conditions of the composite PET application.

Table of Comparison

| Feature | Hybrid Laminate | Monolithic Laminate |

|---|---|---|

| Composition | Multiple layers of different materials | Single uniform layer |

| Flexibility | High flexibility due to layered structure | Less flexible, rigid structure |

| Durability | Enhanced durability with improved resistance to impact | Moderate durability, prone to cracking under stress |

| Weight | Lightweight with optimized mechanical properties | Heavier due to monolithic structure |

| Cost | Generally higher due to complex manufacturing | Lower production cost |

| Application | Advanced aerospace, automotive, and structural uses | Basic structural and decorative applications |

Introduction to Composite Laminates

Composite laminates consist of multiple bonded layers combining different materials to enhance mechanical properties such as strength, stiffness, and impact resistance. Hybrid laminates integrate diverse fiber types like carbon and glass within a single matrix, optimizing performance by leveraging the unique benefits of each fiber. Monolithic laminates, in contrast, utilize a uniform fiber material throughout, offering consistent but less tailored properties compared to hybrid configurations.

Defining Hybrid Laminate and Monolithic Laminate

Hybrid laminates combine multiple layers of different composite materials, such as carbon fiber and fiberglass, to optimize strength, stiffness, and impact resistance. Monolithic laminates consist of uniform layers of a single composite material, providing consistent mechanical properties and simplified manufacturing processes. The hybrid approach enhances performance by leveraging the unique attributes of each material, while monolithic laminates ensure homogeneity and predictability in structural applications.

Material Composition: Hybrid vs. Monolithic

Hybrid laminates combine multiple materials such as carbon fiber, glass fiber, and resin matrices to optimize strength, flexibility, and weight, tailoring performance to specific load requirements. Monolithic laminates consist of a single, uniform material layer providing consistent mechanical properties but limited customization in terms of stiffness and impact resistance. The diverse material composition of hybrid laminates enhances fatigue resistance and damage tolerance compared to the homogeneous structure of monolithic laminates.

Structural Performance Comparison

Hybrid laminates combine multiple fiber types or materials to optimize strength, stiffness, and impact resistance, resulting in superior structural performance compared to monolithic laminates made from a single material. The tailored stacking sequence in hybrid laminates enhances load distribution and damage tolerance, reducing the risk of delamination and improving fatigue resistance. Monolithic laminates may offer simplicity and uniformity but typically lack the versatility and mechanical advantages exhibited by hybrid configurations in demanding structural applications.

Weight and Density Considerations

Hybrid laminates offer a balance of reduced weight and tailored density compared to monolithic laminates, making them ideal for applications requiring specific strength-to-weight ratios. The integration of multiple materials in hybrid laminates allows for optimization of overall density, resulting in lighter components without compromising structural integrity. Monolithic laminates, while generally denser and heavier, provide uniform material properties but may limit weight reduction opportunities in composite design.

Manufacturing Processes and Cost

Hybrid laminates combine different materials such as carbon fiber and fiberglass, requiring complex manufacturing processes like resin transfer molding or vacuum infusion that increase production time and cost. Monolithic laminates consist of a single material layer, enabling simpler, faster, and more cost-effective fabrication methods such as hand lay-up or automated tape laying. The higher initial investment in hybrid laminate manufacturing is often offset by improved performance and material efficiency, whereas monolithic laminates offer budget-friendly solutions with less mechanical complexity.

Durability and Damage Tolerance

Hybrid laminates exhibit superior durability and enhanced damage tolerance compared to monolithic laminates due to their multi-material composition, which effectively dissipates stress and inhibits crack propagation. The interlayer interfaces in hybrid laminates act as barriers, reducing the likelihood of catastrophic failure under cyclic loading and impact conditions. Monolithic laminates, while simpler in structure, often suffer from lower resistance to impact damage and reduced fatigue life, limiting their applications in high-performance environments.

Application Suitability in Industries

Hybrid laminates, combining multiple materials to optimize mechanical properties, excel in industries requiring tailored performance such as aerospace and automotive, offering superior fatigue resistance and weight reduction. Monolithic laminates, composed of a single composite material, are preferred in applications demanding uniformity and cost efficiency, commonly used in construction and marine industries. Selecting between hybrid and monolithic laminates depends on specific industry requirements for strength, durability, and environmental resistance.

Environmental Impact and Sustainability

Hybrid laminates combine multiple materials, offering enhanced durability and reduced material consumption compared to monolithic laminates, which rely on a single material layer. This multi-material structure in hybrid laminates contributes to better resource efficiency and lowers the overall carbon footprint during production. Monolithic laminates typically generate more waste and demand higher energy input, making hybrid laminates a more sustainable choice in composite manufacturing.

Conclusion: Choosing the Right Laminate

Hybrid laminates offer superior impact resistance and improved durability compared to monolithic laminates, making them ideal for high-stress applications. Monolithic laminates excel in lightweight structures and provide consistent mechanical performance with simplified manufacturing processes. Selecting the right laminate depends on balancing strength requirements, weight constraints, and cost-effectiveness for specific composite applications.

Hybrid Laminate vs Monolithic Laminate Infographic

materialdif.com

materialdif.com