Thermoplastic composites offer enhanced impact resistance and recyclability compared to thermoset composites, which provide superior thermal stability and chemical resistance. Thermoplastics can be reshaped and reprocessed multiple times, making them ideal for applications requiring rapid manufacturing and repair. Thermoset composites, once cured, form a rigid and heat-resistant network that maintains structural integrity under high stress and temperature conditions.

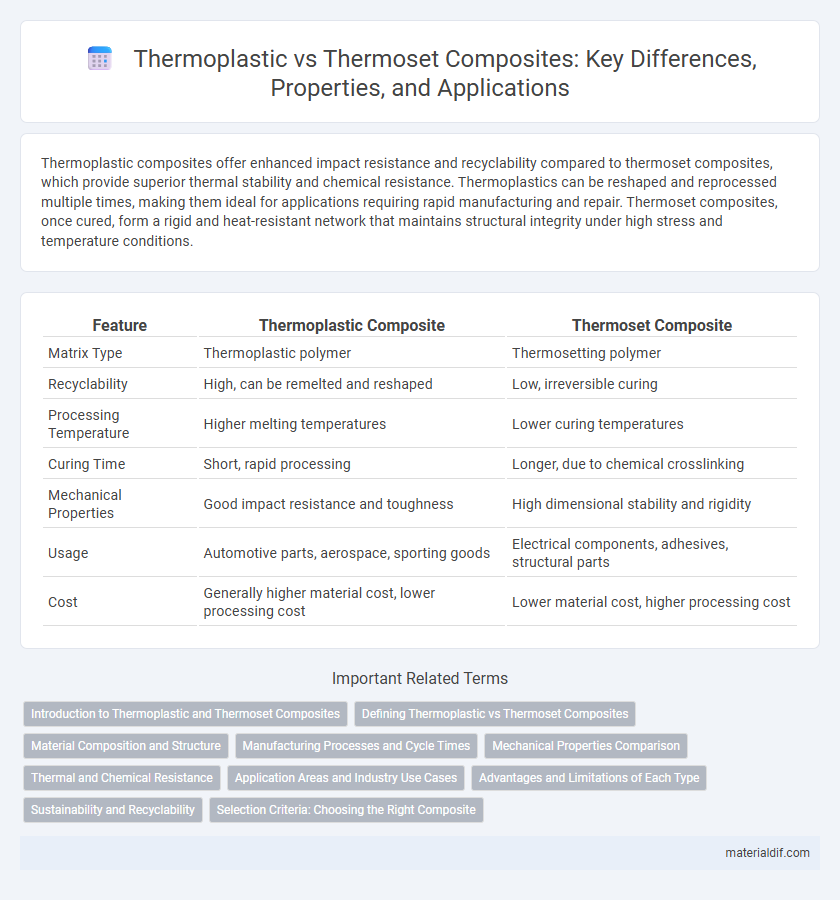

Table of Comparison

| Feature | Thermoplastic Composite | Thermoset Composite |

|---|---|---|

| Matrix Type | Thermoplastic polymer | Thermosetting polymer |

| Recyclability | High, can be remelted and reshaped | Low, irreversible curing |

| Processing Temperature | Higher melting temperatures | Lower curing temperatures |

| Curing Time | Short, rapid processing | Longer, due to chemical crosslinking |

| Mechanical Properties | Good impact resistance and toughness | High dimensional stability and rigidity |

| Usage | Automotive parts, aerospace, sporting goods | Electrical components, adhesives, structural parts |

| Cost | Generally higher material cost, lower processing cost | Lower material cost, higher processing cost |

Introduction to Thermoplastic and Thermoset Composites

Thermoplastic composites consist of a polymer matrix that becomes pliable when heated and solidifies upon cooling, allowing for repeated reshaping and recycling. Thermoset composites, in contrast, involve polymers that undergo irreversible curing, creating a rigid, heat-resistant structure that cannot be remolded once set. The key distinction lies in thermoplastics' recyclability and impact resistance versus thermosets' superior thermal stability and mechanical strength.

Defining Thermoplastic vs Thermoset Composites

Thermoplastic composites consist of a polymer matrix that softens when heated and hardens upon cooling, allowing for easy reshaping and recycling, whereas thermoset composites involve a polymer matrix that irreversibly cures into a rigid structure through a chemical reaction. Thermoplastic matrices like polypropylene, polyethylene, and polyetheretherketone (PEEK) provide high impact resistance and faster production cycles, while thermoset matrices such as epoxy, polyester, and vinyl ester deliver superior thermal stability and chemical resistance. The fundamental distinction lies in their molecular bonding: thermoplastics are linear or branched polymers with reversible phase changes, while thermosets form cross-linked networks creating a permanent, infusible material.

Material Composition and Structure

Thermoplastic composites consist of a polymer matrix that softens upon heating and hardens when cooled, allowing for reprocessing and reshaping; their matrix typically includes materials such as polyethylene, polypropylene, and polyamide. Thermoset composites feature a polymer matrix that undergoes a curing process, creating an infusible and insoluble network, commonly using epoxy, polyester, or phenolic resins. The molecular structure of thermoplastics is linear or branched without cross-linking, providing flexibility, while thermosets have heavily cross-linked molecular chains, resulting in higher thermal stability and mechanical strength.

Manufacturing Processes and Cycle Times

Thermoplastic composites benefit from faster manufacturing processes due to their ability to be reheated and reshaped, enabling shorter cycle times compared to thermoset composites, which require longer curing times to achieve cross-linking of the polymer matrix. Thermoset composites, typically cured through heat and pressure in processes like autoclaving or resin transfer molding, demand extended cycle times ranging from minutes to hours, impacting production efficiency. Thermoplastic composites utilize processes such as thermoforming and injection molding, allowing cycle times as low as seconds to minutes, significantly enhancing scalability and reducing production costs in high-volume manufacturing.

Mechanical Properties Comparison

Thermoplastic composites exhibit higher impact resistance and greater toughness compared to thermoset composites, making them ideal for applications requiring durability and flexibility. Thermoset composites offer superior thermal stability and stiffness due to their cross-linked polymer matrix structure, resulting in enhanced load-bearing capacity and dimensional stability under high temperatures. The fatigue resistance of thermoplastic composites surpasses that of thermoset composites, which are more prone to brittle failure under cyclic loading conditions.

Thermal and Chemical Resistance

Thermoset composites exhibit superior thermal resistance with stability up to 250degC or higher, making them ideal for high-temperature applications compared to thermoplastic composites, which typically withstand temperatures around 120-180degC. Chemical resistance is enhanced in thermoset composites due to their cross-linked polymer structure, offering excellent resistance to solvents, acids, and alkaline substances, while thermoplastic composites have variable chemical resistance depending on their polymer matrix. The choice between thermoplastic and thermoset composites depends on the specific thermal and chemical environment requirements of the application, with thermosets preferred for harsh conditions demanding durability and stability.

Application Areas and Industry Use Cases

Thermoplastic composites are widely used in automotive and aerospace industries for applications requiring impact resistance and rapid manufacturing cycles, such as structural components, interior panels, and lightweight assemblies. Thermoset composites dominate in wind energy, marine, and construction sectors due to their superior thermal stability, high strength-to-weight ratio, and excellent corrosion resistance, ideal for turbine blades, hulls, and infrastructure reinforcements. Industries prioritize thermoplastic composites for recyclability and repairability, whereas thermoset composites are favored for long-term durability and performance in harsh environments.

Advantages and Limitations of Each Type

Thermoplastic composites offer advantages such as high impact resistance, recyclability, and faster processing times due to their ability to be reshaped with heat, making them ideal for applications requiring durability and sustainability. Thermoset composites provide superior thermal stability, chemical resistance, and structural rigidity, which are critical for high-performance and load-bearing applications despite their inability to be remelted or reshaped after curing. Limitations of thermoplastic composites include higher processing temperatures and potential issues with long-term creep, while thermoset composites face challenges with brittleness and difficulty in recycling.

Sustainability and Recyclability

Thermoplastic composites offer superior sustainability and recyclability compared to thermoset composites due to their ability to be reheated and reshaped without degradation. Unlike thermosets, which undergo irreversible chemical curing, thermoplastics can be mechanically recycled and reused, reducing landfill waste and lowering carbon footprints in manufacturing processes. Industry trends increasingly favor thermoplastic composites for eco-friendly applications in automotive and aerospace sectors, driven by regulatory pressures and circular economy goals.

Selection Criteria: Choosing the Right Composite

Thermoplastic composites offer superior impact resistance, faster manufacturing cycles, and recyclability, making them ideal for automotive and aerospace applications requiring durability and sustainability. Thermoset composites provide excellent thermal stability, chemical resistance, and high strength-to-weight ratio, better suited for structural components in wind energy and construction. Selection depends on factors like mechanical performance, production volume, environmental impact, and end-use conditions to ensure optimal composite performance and lifecycle cost.

Thermoplastic Composite vs Thermoset Composite Infographic

materialdif.com

materialdif.com