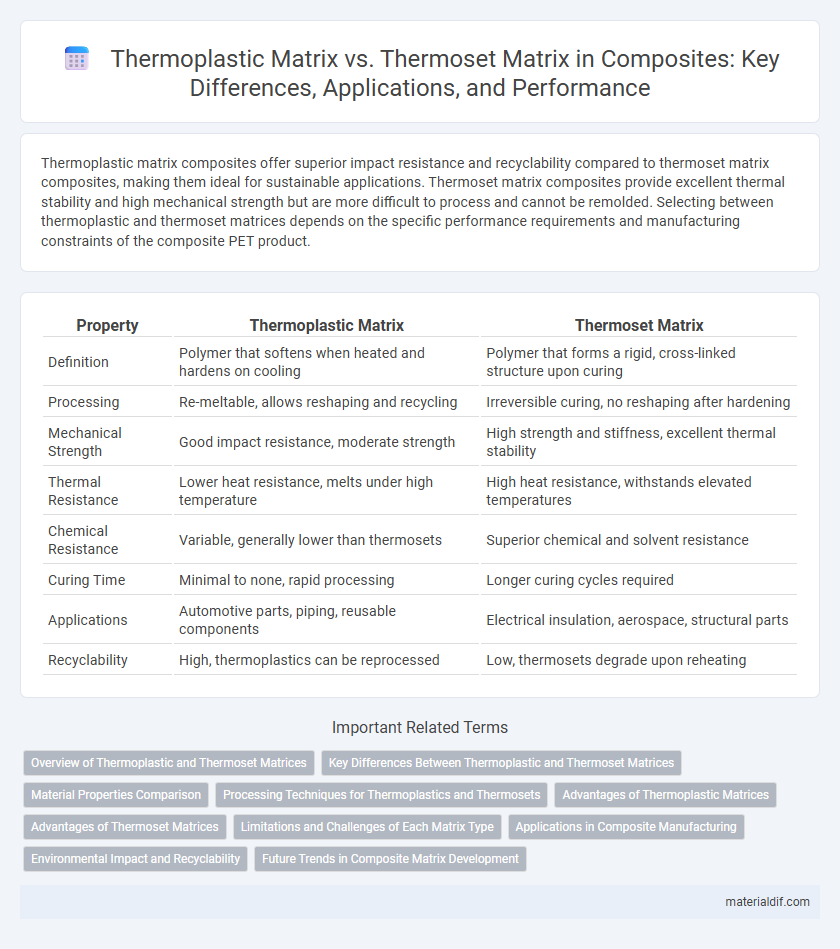

Thermoplastic matrix composites offer superior impact resistance and recyclability compared to thermoset matrix composites, making them ideal for sustainable applications. Thermoset matrix composites provide excellent thermal stability and high mechanical strength but are more difficult to process and cannot be remolded. Selecting between thermoplastic and thermoset matrices depends on the specific performance requirements and manufacturing constraints of the composite PET product.

Table of Comparison

| Property | Thermoplastic Matrix | Thermoset Matrix |

|---|---|---|

| Definition | Polymer that softens when heated and hardens on cooling | Polymer that forms a rigid, cross-linked structure upon curing |

| Processing | Re-meltable, allows reshaping and recycling | Irreversible curing, no reshaping after hardening |

| Mechanical Strength | Good impact resistance, moderate strength | High strength and stiffness, excellent thermal stability |

| Thermal Resistance | Lower heat resistance, melts under high temperature | High heat resistance, withstands elevated temperatures |

| Chemical Resistance | Variable, generally lower than thermosets | Superior chemical and solvent resistance |

| Curing Time | Minimal to none, rapid processing | Longer curing cycles required |

| Applications | Automotive parts, piping, reusable components | Electrical insulation, aerospace, structural parts |

| Recyclability | High, thermoplastics can be reprocessed | Low, thermosets degrade upon reheating |

Overview of Thermoplastic and Thermoset Matrices

Thermoplastic matrices consist of polymers that become moldable above a certain temperature and solidify upon cooling without undergoing chemical change, enabling recyclability and impact resistance in composite materials. Thermoset matrices, formed by irreversible chemical cross-linking during curing, provide superior thermal stability, chemical resistance, and dimensional integrity but cannot be remelted or reshaped. The choice between thermoplastic and thermoset matrices in composites depends on factors such as processing methods, mechanical performance requirements, and end-use applications.

Key Differences Between Thermoplastic and Thermoset Matrices

Thermoplastic matrices are characterized by their ability to soften and melt upon heating, enabling easier recycling and reshaping, while thermoset matrices undergo irreversible curing, forming a rigid, cross-linked structure that offers superior thermal stability and chemical resistance. Thermoplastics exhibit higher impact resistance and flexibility, whereas thermosets provide enhanced mechanical strength, dimensional stability, and resistance to deformation under load. The choice between thermoplastic and thermoset matrices depends on application requirements such as durability, processing methods, and end-of-life recyclability.

Material Properties Comparison

Thermoplastic matrix composites exhibit high ductility, impact resistance, and recyclability, making them suitable for applications requiring toughness and repeatable processing. Thermoset matrix composites offer superior thermal stability, chemical resistance, and dimensional stability due to their crosslinked polymer structure, which enhances mechanical strength under high temperatures. Comparing tensile strength, thermosets typically outperform thermoplastics, but thermoplastics surpass thermosets in fatigue resistance and repairability.

Processing Techniques for Thermoplastics and Thermosets

Thermoplastic composites utilize processing techniques such as injection molding, thermoforming, and extrusion, which allow for rapid melting and reshaping due to the reversible physical bonding of the polymer chains. Thermoset composites require curing processes like compression molding, transfer molding, and resin transfer molding, where irreversible chemical cross-linking occurs to harden the material, providing higher thermal stability and mechanical strength. The choice of processing technique affects cycle time, production cost, and the final composite properties, with thermoplastics offering faster production and recyclability, while thermosets deliver superior performance in high-temperature applications.

Advantages of Thermoplastic Matrices

Thermoplastic matrices offer superior toughness and impact resistance compared to thermoset matrices, enabling enhanced durability in composite materials. Their ability to be reheated and reshaped allows for recyclability and reduced waste, making them environmentally sustainable options. Rapid processing speeds and improved fracture toughness contribute to cost-effective manufacturing and extended service life of composite components.

Advantages of Thermoset Matrices

Thermoset matrices offer superior thermal stability and chemical resistance compared to thermoplastic matrices, making them ideal for high-performance composite applications. Their cross-linked molecular structure provides enhanced mechanical strength, dimensional stability, and resistance to creep under load. These properties result in durable composites suitable for aerospace, automotive, and industrial environments requiring long-term reliability.

Limitations and Challenges of Each Matrix Type

Thermoplastic matrices face challenges such as higher processing temperatures, increased viscosity during molding, and difficulties in achieving strong fiber-matrix adhesion, which impact composite performance and manufacturing efficiency. Thermoset matrices exhibit limitations including brittleness, long curing times, and limited recyclability due to their permanently crosslinked structure, restricting applications where toughness and sustainability are critical. Both matrix types require tailored processing conditions and design considerations to overcome their intrinsic material constraints and optimize composite functionality.

Applications in Composite Manufacturing

Thermoplastic matrix composites are widely used in automotive and aerospace industries due to their superior impact resistance, recyclability, and faster processing times. Thermoset matrix composites dominate applications requiring high thermal stability and mechanical strength, such as wind turbine blades, sporting goods, and aerospace structural components. The selection between thermoplastic and thermoset matrices depends on specific manufacturing requirements, service conditions, and cost considerations in composite fabrication.

Environmental Impact and Recyclability

Thermoplastic matrix composites offer superior environmental benefits due to their recyclability and ability to be reshaped multiple times without significant degradation. Thermoset matrix composites, characterized by cross-linked polymers, present challenges in recycling since they cannot be remelted or reprocessed, often ending in landfill or incineration. The shift toward sustainable composite materials favors thermoplastics for reducing waste and supporting circular economy practices in industries like automotive and aerospace.

Future Trends in Composite Matrix Development

Future trends in composite matrix development emphasize enhancing thermoplastic matrices with improved recyclability, faster processing times, and higher impact resistance, catering to sustainable manufacturing demands. Thermoset matrices are evolving through bio-based resins and advanced curing techniques to reduce environmental impact while maintaining superior mechanical properties. Innovations in nano-reinforcements and hybrid matrix systems aim to combine the advantageous traits of both thermoplastic and thermoset matrices for next-generation composite materials.

Thermoplastic Matrix vs Thermoset Matrix Infographic

materialdif.com

materialdif.com