Pultrusion is a continuous manufacturing process used to create composite profiles with a constant cross-section by pulling fibers through a resin bath and then through a heated die, ensuring high strength and precise dimensions. Filament winding involves winding resin-impregnated fibers around a rotating mandrel to form hollow, cylindrical structures with excellent mechanical properties and tailored fiber orientations. Both methods offer specific advantages: pultrusion excels in producing long, straight profiles with uniform strength, while filament winding is ideal for creating complex, curved shapes with optimized fiber placement.

Table of Comparison

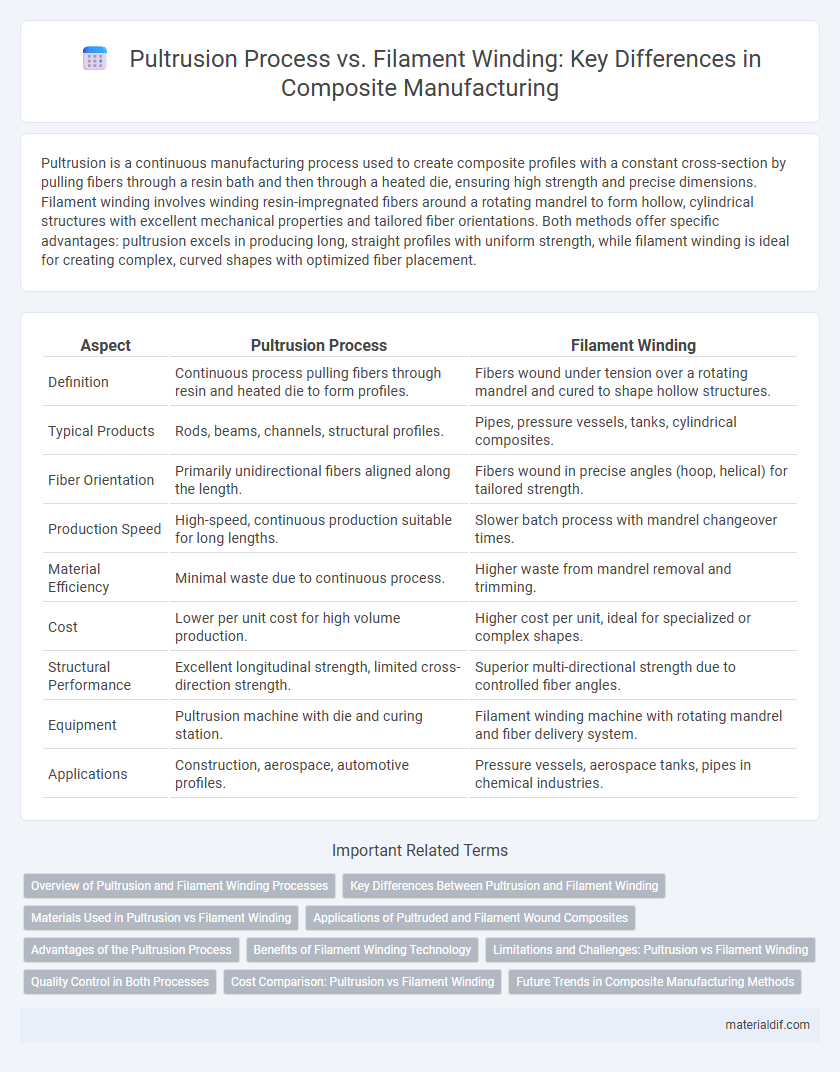

| Aspect | Pultrusion Process | Filament Winding |

|---|---|---|

| Definition | Continuous process pulling fibers through resin and heated die to form profiles. | Fibers wound under tension over a rotating mandrel and cured to shape hollow structures. |

| Typical Products | Rods, beams, channels, structural profiles. | Pipes, pressure vessels, tanks, cylindrical composites. |

| Fiber Orientation | Primarily unidirectional fibers aligned along the length. | Fibers wound in precise angles (hoop, helical) for tailored strength. |

| Production Speed | High-speed, continuous production suitable for long lengths. | Slower batch process with mandrel changeover times. |

| Material Efficiency | Minimal waste due to continuous process. | Higher waste from mandrel removal and trimming. |

| Cost | Lower per unit cost for high volume production. | Higher cost per unit, ideal for specialized or complex shapes. |

| Structural Performance | Excellent longitudinal strength, limited cross-direction strength. | Superior multi-directional strength due to controlled fiber angles. |

| Equipment | Pultrusion machine with die and curing station. | Filament winding machine with rotating mandrel and fiber delivery system. |

| Applications | Construction, aerospace, automotive profiles. | Pressure vessels, aerospace tanks, pipes in chemical industries. |

Overview of Pultrusion and Filament Winding Processes

Pultrusion is a continuous manufacturing process that pulls fibers through a resin bath and then through a heated die to create constant cross-section composite profiles with high strength-to-weight ratios. Filament winding involves winding resin-impregnated fibers onto a rotating mandrel in precise patterns to produce cylindrical or spherical composite structures with excellent mechanical properties. Both processes optimize fiber alignment and resin distribution but differ in product geometry and applications, with pultrusion ideal for linear shapes and filament winding suited for complex rotational forms.

Key Differences Between Pultrusion and Filament Winding

Pultrusion involves continuous pulling of fibers through a resin bath and heated die to create constant cross-section profiles, while filament winding wraps resin-impregnated fibers over a rotating mandrel to form cylindrical or complex shapes. Pultrusion excels in producing high-strength, straight composite parts with uniform thickness, whereas filament winding offers superior fiber orientation control for pressure vessels, pipes, and tanks. Differences also include production speed and tooling complexity, with pultrusion being faster for linear parts and filament winding allowing more design flexibility.

Materials Used in Pultrusion vs Filament Winding

Pultrusion primarily employs continuous fibers such as glass, carbon, or aramid embedded in thermosetting resins like polyester, vinyl ester, or epoxy to create high-strength, lightweight composite profiles. Filament winding utilizes similar fibers but often incorporates advanced resin systems tailored for high-performance applications, with carbon fiber and epoxy resin combinations dominating aerospace and pressure vessel manufacturing. The material selection in pultrusion emphasizes rigidity and uniform cross-sections, while filament winding focuses on optimizing fiber orientation and resin impregnation for enhanced structural integrity under dynamic loads.

Applications of Pultruded and Filament Wound Composites

Pultruded composites are widely used in applications requiring continuous profiles with consistent cross-sections, such as structural beams, ladders, and electrical insulators, due to their high strength-to-weight ratio and corrosion resistance. Filament wound composites excel in manufacturing hollow, cylindrical structures like pressure vessels, pipes, and rocket motor casings because of their superior circumferential strength and customizable fiber orientations. Each process offers distinct advantages tailored to specific industrial applications, with pultrusion favored for linear, constant-shape components and filament winding preferred for complex, rotationally symmetrical parts.

Advantages of the Pultrusion Process

The pultrusion process offers consistent cross-sectional profiles with high dimensional accuracy, making it ideal for producing complex composite shapes efficiently. This method enables continuous production and automation, resulting in lower labor costs and higher throughput compared to filament winding. Pultruded composites exhibit superior fiber alignment, enhancing mechanical properties and ensuring uniform material performance across products.

Benefits of Filament Winding Technology

Filament winding technology offers precise control over fiber placement, resulting in highly uniform and consistent composite structures with superior strength-to-weight ratios. This process enables the production of complex, hollow cylindrical shapes with enhanced mechanical properties and minimal material waste. Its automation capability reduces labor costs and increases repeatability compared to pultrusion, making it ideal for high-performance composite applications such as pressure vessels and pipes.

Limitations and Challenges: Pultrusion vs Filament Winding

Pultrusion faces limitations in producing only constant cross-sectional profiles and struggles with complex geometries, restricting design flexibility compared to filament winding, which can create intricate shapes but encounters challenges with precise fiber placement and mandrel removal. Pultrusion's continuous process is less adaptable to variations in fiber orientation, impacting mechanical property customization, whereas filament winding requires longer cycle times and sophisticated equipment, increasing production costs. Both methods face difficulties in scaling for large or highly complex composite structures, with filament winding being more suitable for hollow, rotationally symmetric parts while pultrusion excels in straight profile applications.

Quality Control in Both Processes

Pultrusion process ensures consistent fiber alignment and resin distribution through continuous monitoring of temperature and line speed, crucial for preventing defects like voids or resin-rich areas. Filament winding quality control depends on precise tension regulation and winding patterns, monitored via sensors to maintain uniform fiber placement and resin impregnation, minimizing structural inconsistencies. Both processes employ non-destructive testing methods such as ultrasonic inspection and infrared thermography to detect internal flaws and ensure composite integrity.

Cost Comparison: Pultrusion vs Filament Winding

Pultrusion offers lower production costs due to continuous manufacturing and minimal labor requirements, making it ideal for high-volume, constant cross-section profiles. Filament winding incurs higher costs due to slower cycle times, complex setups, and increased labor intensity, particularly for large-diameter or customized composite structures. Overall, pultrusion provides a cost-effective solution for standardized parts, whereas filament winding is more expensive but suitable for complex geometries and high-strength composite applications.

Future Trends in Composite Manufacturing Methods

Pultrusion process and filament winding continue to evolve with advancements in automation and material science, driving efficiency and precision in composite manufacturing. Emerging trends emphasize the integration of smart sensors and AI-driven quality control systems to enhance real-time monitoring and reduce defects. Future composite manufacturing methods prioritize sustainability by adopting bio-based resins and recyclable fibers, aligning with industry demands for eco-friendly production.

Pultrusion Process vs Filament Winding Infographic

materialdif.com

materialdif.com