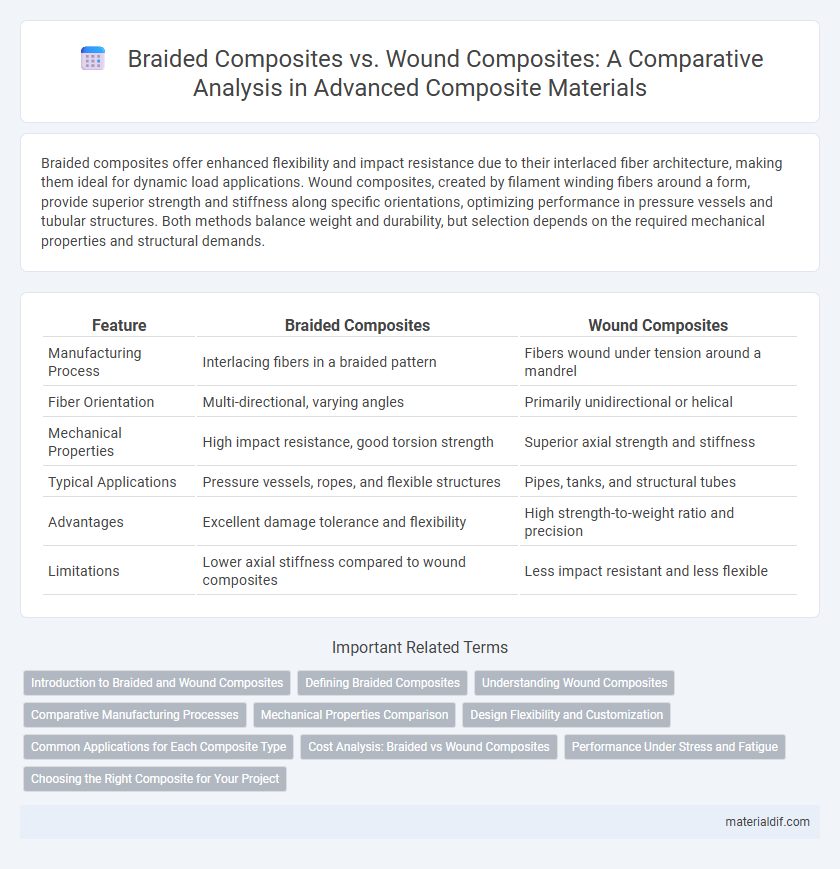

Braided composites offer enhanced flexibility and impact resistance due to their interlaced fiber architecture, making them ideal for dynamic load applications. Wound composites, created by filament winding fibers around a form, provide superior strength and stiffness along specific orientations, optimizing performance in pressure vessels and tubular structures. Both methods balance weight and durability, but selection depends on the required mechanical properties and structural demands.

Table of Comparison

| Feature | Braided Composites | Wound Composites |

|---|---|---|

| Manufacturing Process | Interlacing fibers in a braided pattern | Fibers wound under tension around a mandrel |

| Fiber Orientation | Multi-directional, varying angles | Primarily unidirectional or helical |

| Mechanical Properties | High impact resistance, good torsion strength | Superior axial strength and stiffness |

| Typical Applications | Pressure vessels, ropes, and flexible structures | Pipes, tanks, and structural tubes |

| Advantages | Excellent damage tolerance and flexibility | High strength-to-weight ratio and precision |

| Limitations | Lower axial stiffness compared to wound composites | Less impact resistant and less flexible |

Introduction to Braided and Wound Composites

Braided composites consist of interlaced fibers forming a mesh-like structure that enhances multidirectional strength and flexibility, making them ideal for applications requiring complex stress distribution. Wound composites are produced by winding continuous fiber reinforcements around a mandrel, resulting in high axial strength and superior load-bearing capabilities in cylindrical or tubular components. Both techniques optimize fiber orientation to tailor mechanical properties for aerospace, automotive, and sports equipment industries.

Defining Braided Composites

Braided composites are engineered materials composed of fibers interlaced in a crisscross pattern, enhancing mechanical properties such as tensile strength and impact resistance. The braiding process creates a seamless, flexible structure that distributes loads evenly, making these composites ideal for applications requiring complex geometries and multidirectional stress management. In contrast to wound composites, which rely on fiber layers wrapped in a specific orientation, braided composites offer superior damage tolerance and fatigue resistance due to their integrated fiber architecture.

Understanding Wound Composites

Wound composites utilize continuous fibers tightly wrapped under tension around a mandrel, offering superior strength and precise fiber orientation control for high-performance applications. These composites demonstrate enhanced load distribution and resistance to fatigue compared to braided composites, which interlace fibers in multiple directions. The manufacturing process of wound composites enables customization of fiber angles, optimizing mechanical properties for specific structural demands.

Comparative Manufacturing Processes

Braided composites utilize interlaced yarns woven in a diagonal pattern to form complex, mesh-like structures offering high flexibility and impact resistance. Wound composites are created by wrapping continuous fibers under tension around a mandrel, enabling precise fiber orientation and superior axial strength. The manufacturing of braided composites generally allows faster production for intricate shapes, while wound composites provide enhanced control over fiber alignment for optimized load distribution.

Mechanical Properties Comparison

Braided composites exhibit superior impact resistance and enhanced toughness due to their multidirectional fiber architecture, providing better load distribution compared to wound composites. Wound composites generally offer higher axial strength and stiffness resulting from their unidirectional fiber placement tailored to specific loading conditions. The mechanical performance of braided composites excels in applications requiring complex stress handling, whereas wound composites are favored for high-strength, lightweight structures with predictable load paths.

Design Flexibility and Customization

Braided composites offer superior design flexibility through complex fiber orientations and seamless fabric integration, enabling tailored mechanical properties for specific load conditions. Wound composites, while providing high strength and uniformity, have more limited customization due to constrained fiber placement along predefined paths. The ability of braided composites to conform to intricate shapes and incorporate variable fiber angles ensures enhanced performance in complex structural applications.

Common Applications for Each Composite Type

Braided composites are commonly used in aerospace and automotive applications where enhanced impact resistance and flexibility are essential, such as in fuselage frames and drive shafts. Wound composites find frequent application in pressure vessels, pipes, and wind turbine blades due to their superior strength-to-weight ratio and precise fiber orientation. Both composite types contribute significantly to lightweight structural components that demand high performance and durability.

Cost Analysis: Braided vs Wound Composites

Braided composites generally incur higher manufacturing costs due to complex fiber architecture and slower production rates compared to wound composites, which benefit from automated filament winding processes that reduce labor and time expenses. The material efficiency in wound composites also lowers raw material waste, contributing to overall cost savings in large-scale applications. Cost analysis reveals that while braided composites offer superior mechanical properties, wound composites provide a more economical solution for industries prioritizing budget-friendly production.

Performance Under Stress and Fatigue

Braided composites exhibit superior multi-directional strength and enhanced damage tolerance under cyclic loading due to their interlaced fiber architecture, which distributes stress more evenly and delays crack initiation. Wound composites, with fibers aligned predominantly in the load direction, offer higher strength and stiffness along that axis but may experience localized stress concentrations leading to premature fatigue failure. Performance under stress and fatigue in braided composites is optimized for complex load conditions, whereas wound composites excel in applications requiring unidirectional load-bearing capacity.

Choosing the Right Composite for Your Project

Braided composites offer enhanced flexibility and impact resistance due to their interlaced fiber architecture, making them ideal for applications requiring complex shapes or dynamic loads. Wound composites provide superior strength and stiffness with precise fiber orientation, suitable for cylindrical or tubular structures such as pressure vessels and pipes. Selecting the right composite depends on project-specific factors including load conditions, geometry, and performance requirements to optimize durability and efficiency.

Braided Composites vs Wound Composites Infographic

materialdif.com

materialdif.com