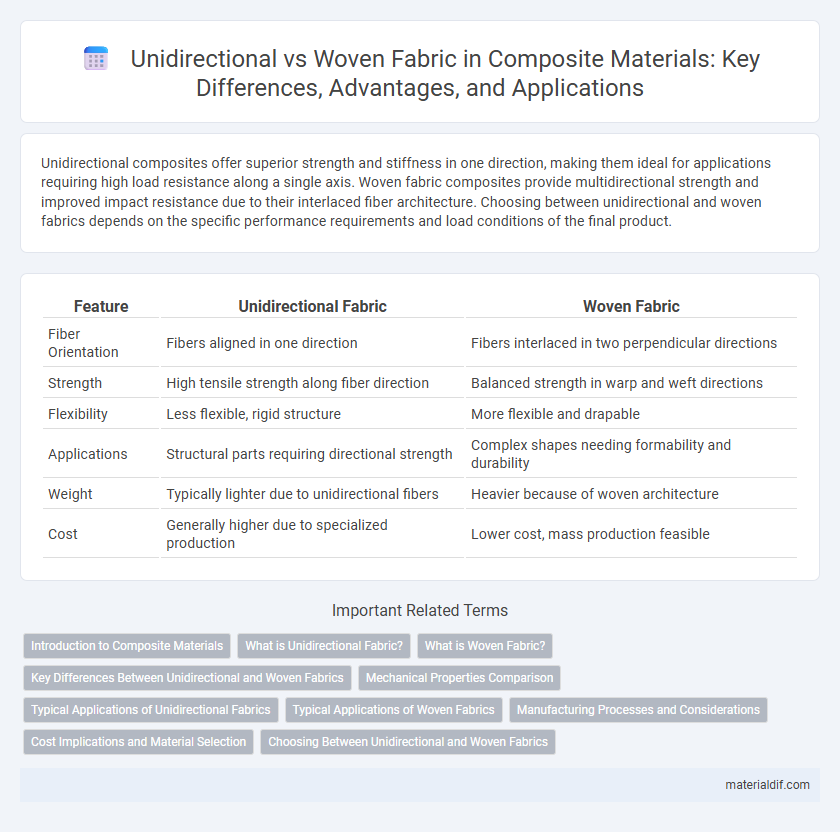

Unidirectional composites offer superior strength and stiffness in one direction, making them ideal for applications requiring high load resistance along a single axis. Woven fabric composites provide multidirectional strength and improved impact resistance due to their interlaced fiber architecture. Choosing between unidirectional and woven fabrics depends on the specific performance requirements and load conditions of the final product.

Table of Comparison

| Feature | Unidirectional Fabric | Woven Fabric |

|---|---|---|

| Fiber Orientation | Fibers aligned in one direction | Fibers interlaced in two perpendicular directions |

| Strength | High tensile strength along fiber direction | Balanced strength in warp and weft directions |

| Flexibility | Less flexible, rigid structure | More flexible and drapable |

| Applications | Structural parts requiring directional strength | Complex shapes needing formability and durability |

| Weight | Typically lighter due to unidirectional fibers | Heavier because of woven architecture |

| Cost | Generally higher due to specialized production | Lower cost, mass production feasible |

Introduction to Composite Materials

Composite materials combine two or more distinct constituents, such as fibers and matrix, to achieve superior mechanical properties. Unidirectional fabric aligns fibers in a single direction, providing maximum strength and stiffness along that axis, ideal for load-bearing applications. Woven fabric interlaces fibers in multiple directions, enhancing impact resistance and dimensional stability, making it suitable for complex shapes and multidirectional stress environments.

What is Unidirectional Fabric?

Unidirectional fabric consists of fibers aligned in a single direction, providing exceptional strength and stiffness along that axis. This fabric is commonly used in composite materials where directional load-bearing capacity is critical, such as aerospace and high-performance sporting goods. Its design optimizes mechanical properties like tensile strength and modulus, making it ideal for tailored structural applications.

What is Woven Fabric?

Woven fabric consists of interlaced yarns arranged in a perpendicular pattern, providing enhanced strength and stability compared to unidirectional fabric. This structure improves resistance to impact and multidirectional stress, making it ideal for composite applications requiring durability and flexibility. Commonly used in aerospace, automotive, and sporting goods, woven fabrics contribute to optimized load distribution and improved mechanical performance.

Key Differences Between Unidirectional and Woven Fabrics

Unidirectional fabrics feature fibers aligned in a single direction, offering maximum strength and stiffness along the fiber axis, ideal for load-bearing applications. Woven fabrics have fibers interlaced at right angles, providing balanced strength, enhanced drapability, and improved resistance to shear forces. The key differences lie in their fiber orientation, mechanical properties, and suitability for complex shapes or high-performance structural components.

Mechanical Properties Comparison

Unidirectional composites exhibit superior tensile strength and stiffness along the fiber direction due to aligned fibers, making them ideal for load-bearing applications requiring high strength-to-weight ratios. Woven fabric composites offer enhanced impact resistance and improved interlaminar shear strength because of their bidirectional fiber architecture, providing better damage tolerance and dimensional stability. Mechanical performance selection depends on specific loading conditions, with unidirectional fabrics excelling in uniaxial stress environments and woven fabrics preferred for multidirectional stress distributions.

Typical Applications of Unidirectional Fabrics

Unidirectional fabrics are primarily used in aerospace components, sporting goods, and high-performance automotive parts due to their exceptional strength and stiffness along the fiber direction. These fabrics offer superior load-bearing capacity in specific directions, making them ideal for structural panels, aircraft wings, and bicycle frames where directional strength is critical. Their high fiber alignment design enables optimized mechanical performance in applications requiring lightweight and high-strength materials.

Typical Applications of Woven Fabrics

Woven fabrics are commonly used in aerospace components, automotive parts, and protective clothing due to their enhanced tensile strength and durability. Their interlaced fiber structure provides superior impact resistance and dimensional stability compared to unidirectional fabrics. These properties make woven fabrics ideal for applications requiring multidirectional load bearing and abrasion resistance.

Manufacturing Processes and Considerations

Unidirectional composites involve aligning fibers in a single direction, simplifying manufacturing processes such as hand lay-up, filament winding, and automated tape laying, which optimize fiber orientation for targeted mechanical properties. In contrast, woven fabric composites require interlacing fibers in two or more directions, necessitating specialized weaving equipment and careful control of fabric tension to maintain dimensional stability and uniformity during molding. Manufacturing woven composites demands greater attention to fiber crimp, resin impregnation, and compaction challenges, influencing the final material performance and structural integrity.

Cost Implications and Material Selection

Unidirectional fabrics offer cost-effective material selection due to their efficient fiber alignment, leading to higher strength-to-weight ratios and reduced resin usage, which lowers manufacturing expenses. Woven fabrics provide enhanced dimensional stability and impact resistance but typically involve higher material and processing costs because of the complex weaving patterns and increased resin consumption. Selecting between unidirectional and woven fabrics depends on balancing budget constraints with performance requirements, as unidirectional composites tend to be more economical for high-performance, lightweight applications.

Choosing Between Unidirectional and Woven Fabrics

When choosing between unidirectional and woven fabrics for composite applications, consider the load direction and mechanical properties required; unidirectional fabrics provide superior tensile strength along fiber alignment, ideal for high-performance, directional stress environments. Woven fabrics offer balanced strength and dimensional stability across multiple directions, making them suitable for complex shapes and impact resistance. Selection should align with structural requirements, processing methods, and desired performance characteristics to optimize composite durability and efficiency.

Unidirectional vs Woven Fabric Infographic

materialdif.com

materialdif.com