Prepreg composites offer superior fiber-to-resin ratio control and consistent quality due to pre-impregnated fibers with precise resin content, enhancing mechanical properties and reducing voids. Wet layup involves manually impregnating dry fibers with resin during layup, providing greater flexibility for complex shapes but often resulting in less uniform resin distribution and potential voids. The choice between prepreg and wet layup depends on production scale, desired strength, and cost considerations.

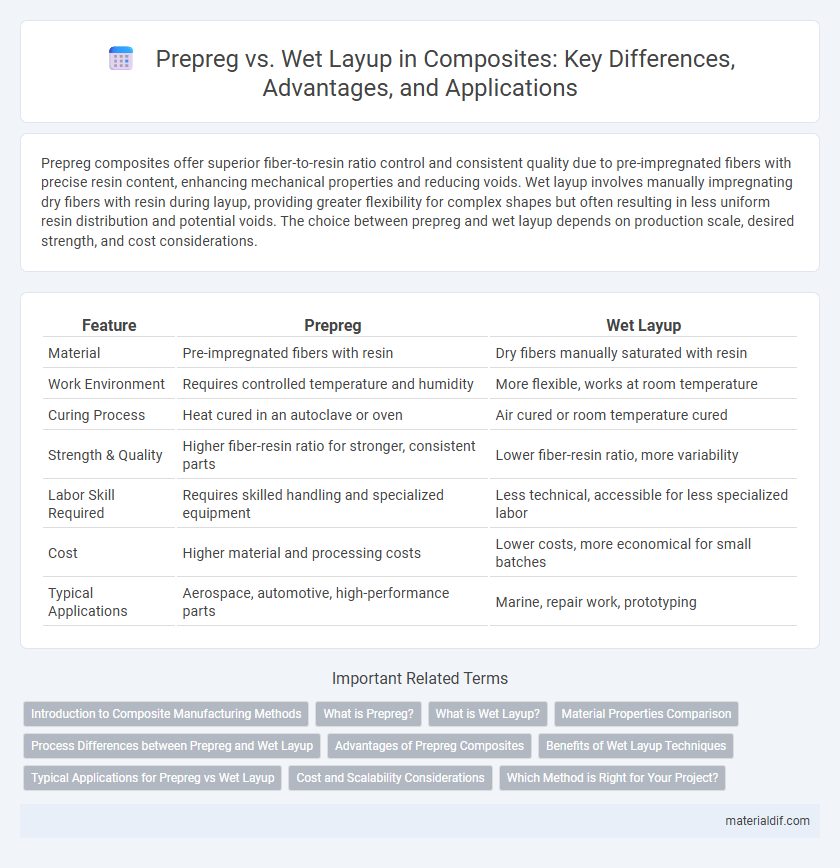

Table of Comparison

| Feature | Prepreg | Wet Layup |

|---|---|---|

| Material | Pre-impregnated fibers with resin | Dry fibers manually saturated with resin |

| Work Environment | Requires controlled temperature and humidity | More flexible, works at room temperature |

| Curing Process | Heat cured in an autoclave or oven | Air cured or room temperature cured |

| Strength & Quality | Higher fiber-resin ratio for stronger, consistent parts | Lower fiber-resin ratio, more variability |

| Labor Skill Required | Requires skilled handling and specialized equipment | Less technical, accessible for less specialized labor |

| Cost | Higher material and processing costs | Lower costs, more economical for small batches |

| Typical Applications | Aerospace, automotive, high-performance parts | Marine, repair work, prototyping |

Introduction to Composite Manufacturing Methods

Prepreg and wet layup are fundamental composite manufacturing methods that differ primarily in resin application and curing processes. Prepreg involves pre-impregnated fibers with controlled resin content, offering superior consistency and mechanical properties after curing in an autoclave or oven. Wet layup requires manual resin application onto dry fibers, providing flexibility and lower initial cost but resulting in less uniform lamina and potential voids in the final composite structure.

What is Prepreg?

Prepreg refers to composite fiber materials, such as carbon or glass fibers, pre-impregnated with a precise amount of resin, typically epoxy, which is partially cured to a tacky state for enhanced handling. This pre-impregnation ensures consistent resin distribution, superior mechanical properties, and improved fiber-resin bonding compared to wet layup processes. Stored under refrigerated conditions, prepregs require controlled curing in an autoclave or press, enabling high-performance composite production used extensively in aerospace, automotive, and sporting goods industries.

What is Wet Layup?

Wet layup is a composite manufacturing process where dry fiber reinforcement is manually impregnated with liquid resin directly on the mold surface before curing. This technique offers greater flexibility for creating complex shapes and is commonly used in boat building, aerospace, and automotive industries. Wet layup typically requires longer curing times and may result in lower fiber-to-resin ratios compared to prepreg methods.

Material Properties Comparison

Prepreg materials exhibit superior fiber-to-resin ratio control and enhanced mechanical properties such as higher tensile strength and stiffness compared to wet layup composites. The uniform resin distribution in prepreg results in improved fiber wetting and reduced void content, leading to better fatigue resistance and durability. Wet layup, while more flexible in field applications, generally shows lower interlaminar shear strength and higher porosity due to manual resin impregnation variability.

Process Differences between Prepreg and Wet Layup

Prepreg involves fibers that are pre-impregnated with a precise resin matrix, allowing for controlled curing under heat and pressure, resulting in consistent laminate quality. Wet layup requires manual resin application to dry fibers, making the process more labor-intensive and susceptible to variations in resin content and thickness. The curing in wet layup often occurs at room temperature, leading to longer curing times compared to the autoclave or oven curing used for prepreg materials.

Advantages of Prepreg Composites

Prepreg composites offer superior fiber alignment and resin control compared to wet layup, resulting in enhanced mechanical properties and consistent laminate quality. The pre-impregnated fibers ensure optimal resin content, reducing voids and increasing strength-to-weight ratio in composite structures. Manufacturing with prepregs also improves repeatability and reduces waste, leading to better performance in aerospace, automotive, and high-performance applications.

Benefits of Wet Layup Techniques

Wet layup techniques offer enhanced flexibility in complex shapes and large structures due to the direct application of resin and reinforcement materials on-site. This method reduces upfront costs by eliminating the need for pre-impregnated fabrics and autoclave processing, making it ideal for custom, low-volume, or repair work. Additionally, wet layup enables easier monitoring and adjustment of resin content during layup, improving material consistency and performance in diverse environmental conditions.

Typical Applications for Prepreg vs Wet Layup

Prepreg composites are typically used in aerospace, automotive, and high-performance sporting goods due to their superior strength, precise fiber-resin ratio, and consistent quality. Wet layup is commonly favored for marine, wind energy, and repair applications where cost-efficiency and ease of use outweigh the need for exact resin control and advanced curing cycles. Prepreg suits environments demanding high structural integrity and weight savings, while wet layup excels in large-scale or prototype projects with flexible manufacturing requirements.

Cost and Scalability Considerations

Prepreg composites generally incur higher upfront costs due to specialized materials and controlled curing processes compared to wet layup techniques, which use more accessible materials and manual application, reducing initial expenses. Scalability favors prepreg methods for consistent, high-volume production with automated processes, while wet layup is more suitable for low-volume, custom projects because of its labor-intensive nature and longer cure times. Cost-efficiency in scaled production often aligns with prepreg, whereas flexibility and lower capital investment benefit wet layup applications.

Which Method is Right for Your Project?

Prepreg offers superior fiber-to-resin ratio and consistent mechanical properties, making it ideal for high-performance aerospace and automotive composites requiring precision and strength. Wet layup is cost-effective and flexible, suited for large or complex shapes where tooling and tight tolerances are less critical. Selecting between prepreg and wet layup depends on budget constraints, production volume, and the required structural performance of the composite part.

Prepreg vs Wet Layup Infographic

materialdif.com

materialdif.com