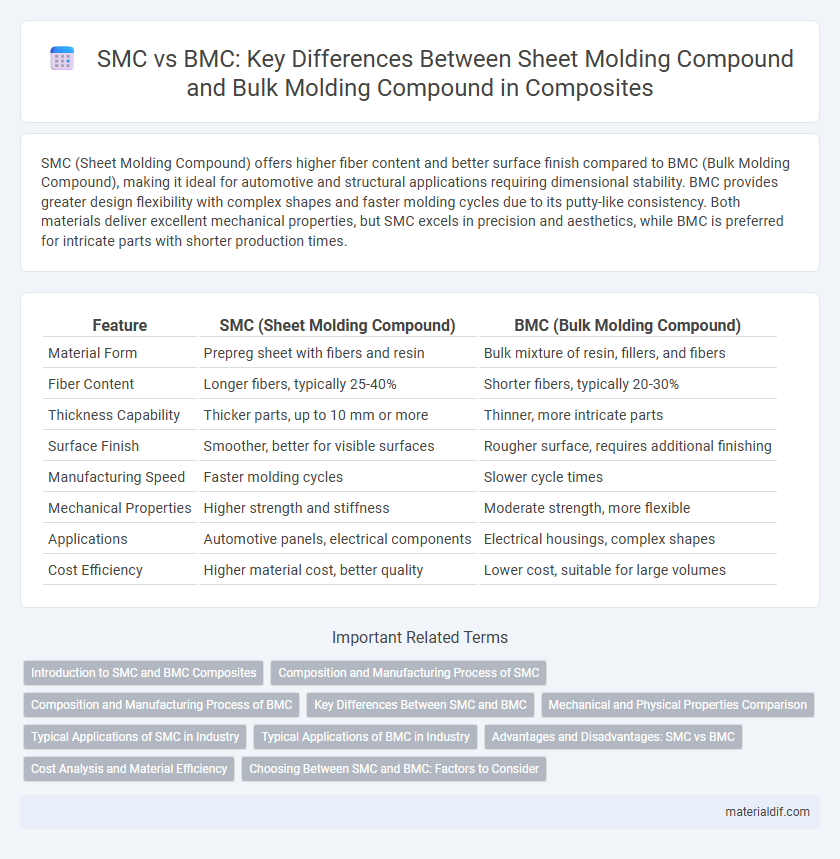

SMC (Sheet Molding Compound) offers higher fiber content and better surface finish compared to BMC (Bulk Molding Compound), making it ideal for automotive and structural applications requiring dimensional stability. BMC provides greater design flexibility with complex shapes and faster molding cycles due to its putty-like consistency. Both materials deliver excellent mechanical properties, but SMC excels in precision and aesthetics, while BMC is preferred for intricate parts with shorter production times.

Table of Comparison

| Feature | SMC (Sheet Molding Compound) | BMC (Bulk Molding Compound) |

|---|---|---|

| Material Form | Prepreg sheet with fibers and resin | Bulk mixture of resin, fillers, and fibers |

| Fiber Content | Longer fibers, typically 25-40% | Shorter fibers, typically 20-30% |

| Thickness Capability | Thicker parts, up to 10 mm or more | Thinner, more intricate parts |

| Surface Finish | Smoother, better for visible surfaces | Rougher surface, requires additional finishing |

| Manufacturing Speed | Faster molding cycles | Slower cycle times |

| Mechanical Properties | Higher strength and stiffness | Moderate strength, more flexible |

| Applications | Automotive panels, electrical components | Electrical housings, complex shapes |

| Cost Efficiency | Higher material cost, better quality | Lower cost, suitable for large volumes |

Introduction to SMC and BMC Composites

Sheet Molding Compound (SMC) and Bulk Molding Compound (BMC) are widely used types of composite materials combining thermosetting resins with glass fibers and fillers for enhanced mechanical properties. SMC is characterized by its semi-finished sheet form, offering superior surface finish and dimensional stability, commonly used in automotive body panels and electrical components. BMC, typically supplied as a dough-like mixture, facilitates injection molding processes and is preferred for complex, high-volume parts requiring excellent thermal and electrical insulation.

Composition and Manufacturing Process of SMC

Sheet Molding Compound (SMC) consists of a fiberglass-reinforced polyester resin matrix combined with fillers, catalysts, and chemical additives, pre-impregnated into a continuous sheet format. The manufacturing process involves layering resin-coated fiberglass mats, then compression molding under heat and pressure to form highly uniform and dimensionally stable composite parts. This controlled process enables precise fiber orientation and consistent resin distribution, enhancing mechanical properties compared to Bulk Molding Compound (BMC), which utilizes a more granular, mixed approach.

Composition and Manufacturing Process of BMC

Bulk Molding Compound (BMC) is a ready-to-mold fiber-reinforced composite material primarily composed of short glass fibers, thermosetting resins such as unsaturated polyester or epoxy, fillers like calcium carbonate or clay, and various additives to enhance flow and electrical properties. The manufacturing process of BMC involves blending the dry fibers with the resin paste and fillers to form a homogeneous compound, followed by compression molding or injection molding at elevated temperatures and pressures to shape and cure the parts. This process ensures uniform fiber distribution and precise control over material properties, making BMC suitable for complex, high-volume production with consistent mechanical and electrical performance.

Key Differences Between SMC and BMC

SMC (Sheet Molding Compound) and BMC (Bulk Molding Compound) differ primarily in their form and application processes, with SMC being a pre-compressed sheet ideal for large, complex parts and BMC a dough-like material suited for smaller, intricate components. SMC offers superior surface finish and dimensional stability due to its controlled fiber orientation, while BMC provides better flowability for molding detailed parts with high filler content. Both materials use thermosetting resins, but SMC typically incorporates longer fibers for enhanced mechanical strength, whereas BMC is favored for high-volume production with shorter cycle times.

Mechanical and Physical Properties Comparison

SMC (Sheet Molding Compound) exhibits superior mechanical properties such as higher tensile strength and enhanced impact resistance compared to BMC (Bulk Molding Compound) due to its continuous fiber reinforcement and controlled fiber orientation. Physically, SMC offers better surface finish and dimensional stability, making it ideal for complex, high-strength applications, whereas BMC typically has higher filler content, resulting in increased density but lower mechanical performance. These differences make SMC more suitable for structural components requiring high durability and precise tolerances, while BMC is preferred for simpler molded parts with lower mechanical demands.

Typical Applications of SMC in Industry

Sheet Molding Compound (SMC) is widely utilized in the automotive industry for manufacturing body panels, hoods, and bumper beams due to its high strength-to-weight ratio and excellent surface finish. SMC is also prevalent in electrical enclosures and consumer appliance housings, where its superior electrical insulation and corrosion resistance are critical. Its ability to be molded into complex shapes with tight tolerances makes SMC ideal for aerospace structural components and industrial machinery parts.

Typical Applications of BMC in Industry

Bulk molding compound (BMC) is widely used in electrical components due to its excellent insulating properties and flame retardance. It is also prevalent in automotive applications such as housings, connectors, and brackets, where high mechanical strength and dimensional stability are required. Additionally, BMC finds applications in consumer goods and industrial equipment, offering corrosion resistance and ease of molding complex shapes.

Advantages and Disadvantages: SMC vs BMC

SMC offers superior surface finish and higher strength-to-weight ratio compared to BMC, making it ideal for large, complex parts with intricate details. BMC provides better flowability and is suitable for smaller, more intricate components but generally results in lower dimensional stability and mechanical properties. While SMC is costlier due to longer curing cycles and tooling requirements, BMC benefits from faster cycle times and lower material costs but may suffer from increased shrinkage and lower impact resistance.

Cost Analysis and Material Efficiency

SMC (Sheet Molding Compound) generally incurs higher upfront costs due to its pre-formed sheets and precise fiber alignment, which improve material efficiency by reducing waste during molding. BMC (Bulk Molding Compound) offers lower raw material and processing costs but often generates more scrap, impacting overall cost-effectiveness. In cost analysis, SMC's superior fiber orientation and reduced cycle time translate to better material utilization and potentially lower total production costs for high-volume, complex parts.

Choosing Between SMC and BMC: Factors to Consider

Choosing between SMC (Sheet Molding Compound) and BMC (Bulk Molding Compound) involves evaluating factors such as part complexity, surface finish requirements, and production volume. SMC offers superior surface quality and is ideal for large, flat components with high aesthetic demands, while BMC suits intricate shapes and provides excellent mechanical properties for smaller parts. Cost considerations and molding cycle times also influence decision-making, with SMC favoring high-volume, high-precision applications and BMC supporting faster cycles for complex geometries.

SMC vs BMC (Sheet molding compound vs Bulk molding compound) Infographic

materialdif.com

materialdif.com