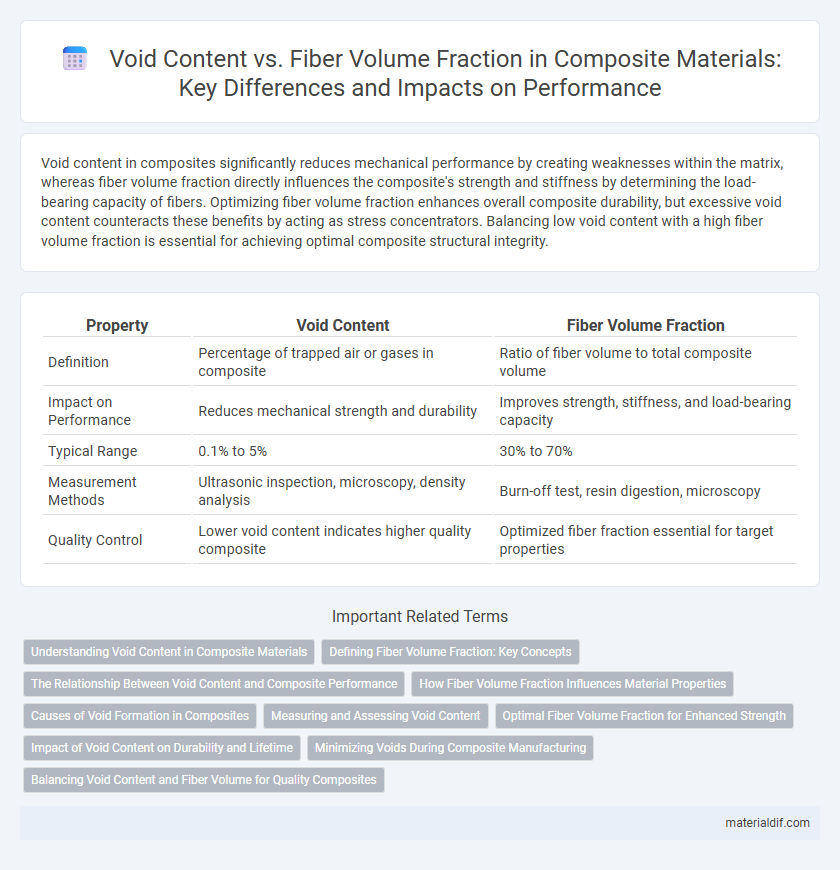

Void content in composites significantly reduces mechanical performance by creating weaknesses within the matrix, whereas fiber volume fraction directly influences the composite's strength and stiffness by determining the load-bearing capacity of fibers. Optimizing fiber volume fraction enhances overall composite durability, but excessive void content counteracts these benefits by acting as stress concentrators. Balancing low void content with a high fiber volume fraction is essential for achieving optimal composite structural integrity.

Table of Comparison

| Property | Void Content | Fiber Volume Fraction |

|---|---|---|

| Definition | Percentage of trapped air or gases in composite | Ratio of fiber volume to total composite volume |

| Impact on Performance | Reduces mechanical strength and durability | Improves strength, stiffness, and load-bearing capacity |

| Typical Range | 0.1% to 5% | 30% to 70% |

| Measurement Methods | Ultrasonic inspection, microscopy, density analysis | Burn-off test, resin digestion, microscopy |

| Quality Control | Lower void content indicates higher quality composite | Optimized fiber fraction essential for target properties |

Understanding Void Content in Composite Materials

Void content in composite materials refers to the volume fraction of air pockets or unfilled spaces within the composite matrix, which can significantly impact mechanical properties and structural integrity. A higher void content reduces fiber volume fraction, leading to decreased strength, stiffness, and fatigue resistance in carbon fiber or glass fiber composites. Controlling void content through optimized manufacturing processes like vacuum bagging or resin infusion is crucial for achieving desired performance in aerospace, automotive, and sporting applications.

Defining Fiber Volume Fraction: Key Concepts

Fiber volume fraction (FVF) represents the ratio of the volume of reinforcing fibers to the total volume of the composite material, a critical parameter influencing mechanical properties such as strength and stiffness. Void content, which refers to the presence of air pockets or voids within the composite, can reduce the effective fiber volume fraction and degrade material performance by introducing weak points. Precise measurement and control of fiber volume fraction ensure optimal composite quality and predictability in structural applications.

The Relationship Between Void Content and Composite Performance

Void content in composite materials significantly reduces fiber volume fraction, leading to compromised mechanical properties such as tensile strength and fatigue resistance. Higher void content creates stress concentration points that initiate cracks, ultimately deteriorating composite durability and overall performance. Maintaining low void content is crucial to ensuring optimal fiber volume fraction and maximizing the structural integrity of composite components.

How Fiber Volume Fraction Influences Material Properties

Fiber volume fraction critically influences the mechanical properties of composite materials by determining the proportion of reinforcement within the matrix. Higher fiber volume fractions generally increase stiffness, strength, and load-bearing capacity, while reducing void content enhances interfacial bonding and minimization of defects. Optimizing fiber volume fraction and minimizing voids leads to improved durability, fatigue resistance, and overall composite performance.

Causes of Void Formation in Composites

Void formation in composites primarily results from trapped air or volatiles during the manufacturing process, leading to significant reductions in fiber volume fraction and mechanical performance. Inadequate resin flow, improper curing cycles, and excessive fiber packing contribute to void entrapment by preventing complete resin infiltration and consolidation of fiber bundles. These voids decrease load transfer efficiency between fibers and matrix, causing critical defects that undermine composite structural integrity.

Measuring and Assessing Void Content

Measuring void content in composites involves techniques such as micro-CT scanning, optical microscopy, and acid digestion to accurately quantify trapped air or gas pockets, which directly influence fiber volume fraction (FVF) calculations. Precise assessment of void content is essential to adjust the theoretical FVF for realistic mechanical property predictions and ensure composite structural integrity. Understanding the correlation between void content and FVF enables optimization of manufacturing processes like resin transfer molding and autoclave curing for enhanced composite performance.

Optimal Fiber Volume Fraction for Enhanced Strength

Optimal fiber volume fraction in composites typically ranges between 40% to 60%, balancing void content and mechanical strength for enhanced performance. Excessive fiber volume fraction above this range often leads to increased void content, which creates stress concentrations and weakens the composite. Maintaining an optimal fiber volume fraction minimizes void content and maximizes load transfer efficiency, resulting in superior composite strength and durability.

Impact of Void Content on Durability and Lifetime

Void content critically undermines the durability and lifetime of composite materials by creating weak points that facilitate crack initiation and propagation under mechanical stress. Higher void content reduces the effective fiber volume fraction, diminishing load transfer efficiency and causing premature failure through delamination and matrix cracking. Maintaining low void content below 1% is essential for optimizing the fiber volume fraction and ensuring long-term structural integrity in high-performance composites.

Minimizing Voids During Composite Manufacturing

Minimizing void content in composite materials is crucial for enhancing fiber volume fraction and overall structural integrity. Techniques such as vacuum-assisted resin transfer molding (VARTM) and optimized curing cycles reduce air entrapment and ensure uniform resin distribution. Maintaining low void content improves mechanical properties, increases load-bearing capacity, and extends composite durability in aerospace and automotive applications.

Balancing Void Content and Fiber Volume for Quality Composites

Balancing void content and fiber volume fraction is critical for optimizing the mechanical properties and durability of composite materials. High fiber volume fraction enhances strength and stiffness, while minimizing void content reduces the risk of delamination and moisture ingress. Achieving an ideal balance ensures consistent composite quality and long-term performance in aerospace and automotive applications.

Void Content vs Fiber Volume Fraction Infographic

materialdif.com

materialdif.com