Kevlar and aramid both belong to the same family of high-performance synthetic fibers, with Kevlar being a specific brand of aramid developed by DuPont. Kevlar is renowned for its superior strength-to-weight ratio, exceptional impact resistance, and thermal stability, making it ideal for aerospace, ballistic protection, and automotive applications. While all Kevlar is aramid, not all aramids share the precise properties of Kevlar, as variations in molecular structure and processing influence performance characteristics across different aramid fibers.

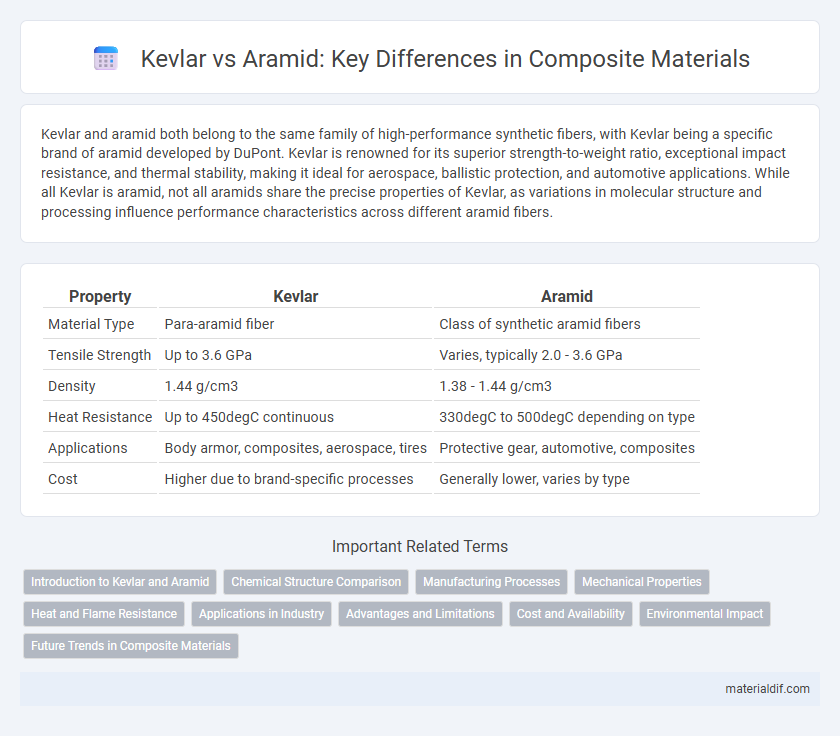

Table of Comparison

| Property | Kevlar | Aramid |

|---|---|---|

| Material Type | Para-aramid fiber | Class of synthetic aramid fibers |

| Tensile Strength | Up to 3.6 GPa | Varies, typically 2.0 - 3.6 GPa |

| Density | 1.44 g/cm3 | 1.38 - 1.44 g/cm3 |

| Heat Resistance | Up to 450degC continuous | 330degC to 500degC depending on type |

| Applications | Body armor, composites, aerospace, tires | Protective gear, automotive, composites |

| Cost | Higher due to brand-specific processes | Generally lower, varies by type |

Introduction to Kevlar and Aramid

Kevlar and Aramid are high-performance synthetic fibers widely used in composite materials for their exceptional strength and durability. Kevlar, a brand of aramid fiber developed by DuPont, is renowned for its superior tensile strength-to-weight ratio, making it ideal in ballistic protection and aerospace applications. Aramid fibers, including brands like Twaron and Technora, share similar chemical structures with Kevlar but differ in mechanical properties and thermal resistance, allowing tailored composite solutions in automotive and industrial sectors.

Chemical Structure Comparison

Kevlar and generic aramid fibers share a similar aromatic polyamide backbone characterized by repeating para-phenylene terephthalamide units, which confer exceptional strength and thermal stability. Kevlar distinguishes itself by a highly ordered para-orientation of amide linkages, resulting in greater tensile strength and impact resistance compared to meta-oriented aramids like Nomex. The chemical structure's linearity and strong hydrogen bonding in Kevlar's molecular chains enhance its rigidity and durability in composite materials.

Manufacturing Processes

Kevlar and aramid fibers share similar chemical structures but differ primarily in their manufacturing processes, which influence their performance characteristics. Kevlar is produced by a solution polymerization process involving concentrated sulfuric acid to dissolve the polymer, followed by spinning fibers through air gap spinning, allowing high molecular orientation and crystallinity. Aramid fibers generally use variations of wet spinning techniques to align polymer chains, impacting tensile strength and thermal stability distinct from Kevlar's specific production method.

Mechanical Properties

Kevlar and aramid fibers both exhibit exceptional mechanical properties, with Kevlar offering a tensile strength of around 3,620 MPa and an elastic modulus of approximately 130 GPa, making it highly suitable for ballistic protection and structural reinforcement. Aramid fibers generally show high impact resistance and fatigue strength, while maintaining lightweight characteristics critical for aerospace and automotive composites. Despite their similarities, Kevlar typically provides superior toughness and lower creep deformation under sustained loads compared to generic aramid fibers.

Heat and Flame Resistance

Kevlar and aramid fibers both exhibit exceptional heat and flame resistance, with Kevlar typically outperforming standard aramid fibers due to its higher decomposition temperature around 450degC. Kevlar maintains structural integrity and strength under prolonged exposure to extreme heat, making it ideal for protective clothing and aerospace applications. While aramid fibers offer strong thermal stability, Kevlar's superior resistance to flame and thermal degradation ensures enhanced durability and safety in high-temperature environments.

Applications in Industry

Kevlar and aramid fibers are widely used in aerospace, automotive, and military industries due to their high strength-to-weight ratio and excellent impact resistance. Kevlar is preferred for ballistic protection and body armor because of its superior tensile strength and energy absorption capabilities. In contrast, aramid fibers find broader applications in aerospace components, automotive tires, and protective clothing, benefiting from their thermal stability and chemical resistance.

Advantages and Limitations

Kevlar, a patented aramid fiber developed by DuPont, offers exceptional tensile strength, impact resistance, and thermal stability, making it ideal for ballistic armor and aerospace composites. Aramid fibers in general provide excellent strength-to-weight ratios and chemical resistance but suffer from UV degradation and moisture absorption, which can reduce durability and performance over time. Kevlar's superior toughness and lower density set it apart from other aramids, although it remains vulnerable to compression weaknesses and higher cost compared to alternative reinforcing fibers.

Cost and Availability

Kevlar, a specific type of aramid fiber, generally commands higher prices due to its established brand and extensive performance certifications in industries like aerospace and defense. Aramid fibers overall, which include variations like Nomex and Twaron, offer a broader range of cost options and availability, with some types more accessible for commercial applications. Supply chain factors and production volumes heavily influence the cost disparity, making bulk aramid fibers more affordable and widely available than branded Kevlar products.

Environmental Impact

Kevlar and Aramid fibers both belong to the class of aromatic polyamides, but Kevlar, a proprietary brand of aramid, often involves energy-intensive manufacturing processes resulting in higher carbon emissions. Aramid fibers, in general, present challenges in biodegradability and recycling, contributing to persistent environmental waste concerns. Innovations in sustainable production methods and recycling technologies are crucial to reducing the overall environmental impact of both Kevlar and other aramid composites.

Future Trends in Composite Materials

Kevlar and other aramid fibers remain at the forefront of advanced composite materials due to their exceptional strength-to-weight ratio and thermal stability. Future trends emphasize enhancing the integration of Kevlar with nanomaterials and bio-based resins to improve mechanical performance and environmental sustainability. Innovations in hybrid composites combining Kevlar with carbon or glass fibers aim to optimize durability and impact resistance for aerospace, automotive, and protective gear applications.

Kevlar vs Aramid Infographic

materialdif.com

materialdif.com