CFRP offers superior strength-to-weight ratio and stiffness compared to GFRP, making it ideal for high-performance applications such as aerospace and automotive industries. GFRP, while less expensive and more impact-resistant, provides good durability and corrosion resistance, suitable for construction and marine uses. The choice between CFRP and GFRP depends on balancing cost, mechanical performance, and environmental exposure requirements.

Table of Comparison

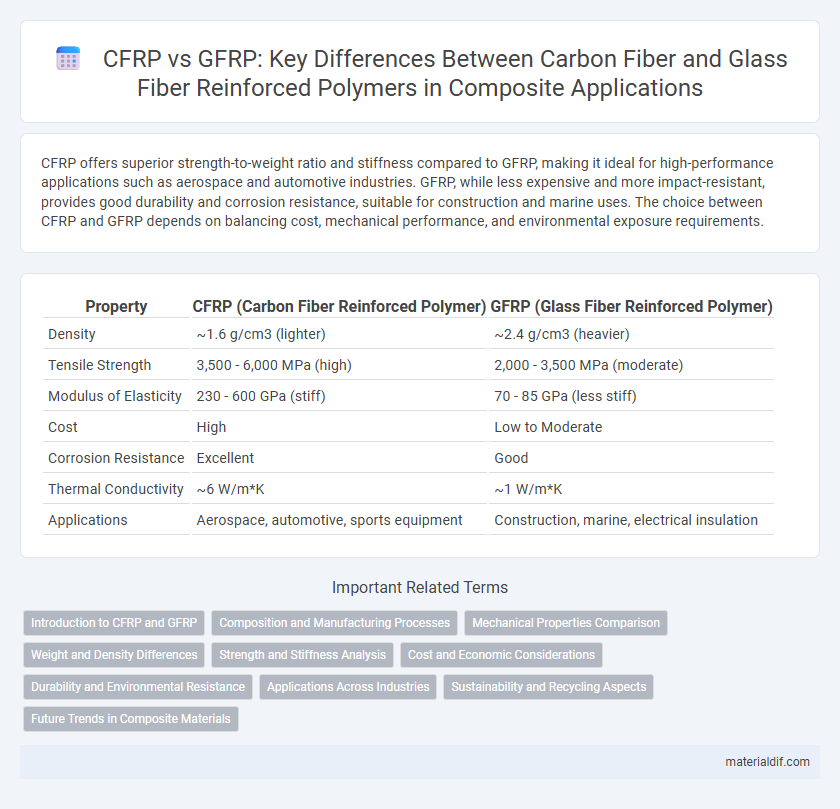

| Property | CFRP (Carbon Fiber Reinforced Polymer) | GFRP (Glass Fiber Reinforced Polymer) |

|---|---|---|

| Density | ~1.6 g/cm3 (lighter) | ~2.4 g/cm3 (heavier) |

| Tensile Strength | 3,500 - 6,000 MPa (high) | 2,000 - 3,500 MPa (moderate) |

| Modulus of Elasticity | 230 - 600 GPa (stiff) | 70 - 85 GPa (less stiff) |

| Cost | High | Low to Moderate |

| Corrosion Resistance | Excellent | Good |

| Thermal Conductivity | ~6 W/m*K | ~1 W/m*K |

| Applications | Aerospace, automotive, sports equipment | Construction, marine, electrical insulation |

Introduction to CFRP and GFRP

Carbon fiber reinforced polymer (CFRP) offers superior strength-to-weight ratio and stiffness compared to glass fiber reinforced polymer (GFRP), making it ideal for high-performance aerospace and automotive applications. GFRP, known for its cost-effectiveness and corrosion resistance, is widely used in construction, marine, and consumer goods where moderate mechanical properties suffice. Both composites consist of fiber reinforcements embedded in a polymer matrix, but CFRP's carbon fibers provide enhanced tensile strength and fatigue resistance relative to GFRP's glass fibers.

Composition and Manufacturing Processes

Carbon fiber reinforced polymer (CFRP) consists of carbon fibers embedded in a polymer matrix, offering superior strength-to-weight ratio and stiffness, while glass fiber reinforced polymer (GFRP) uses glass fibers, providing cost-effective corrosion resistance and flexibility. CFRP manufacturing commonly involves autoclave curing or resin transfer molding to achieve high fiber volume fractions, whereas GFRP often utilizes hand lay-up or pultrusion methods suitable for large-scale production with lower processing costs. The distinct fiber types and curing techniques directly influence mechanical properties, durability, and application suitability in aerospace, automotive, and construction industries.

Mechanical Properties Comparison

Carbon fiber reinforced polymer (CFRP) exhibits superior tensile strength and stiffness compared to glass fiber reinforced polymer (GFRP), making CFRP ideal for high-performance structural applications. CFRP typically has a tensile strength of 3,500 MPa and a modulus of elasticity around 230 GPa, whereas GFRP's tensile strength ranges from 1,000 to 3,000 MPa with a modulus near 70 GPa. While GFRP offers better impact resistance and cost-effectiveness, CFRP delivers enhanced fatigue resistance and weight savings crucial for aerospace and automotive industries.

Weight and Density Differences

Carbon fiber reinforced polymer (CFRP) has a density of approximately 1.6 g/cm3, significantly lower than glass fiber reinforced polymer (GFRP), which typically ranges from 2.0 to 2.5 g/cm3. This density difference results in CFRP components being lighter by about 25-35%, offering superior strength-to-weight ratios essential for aerospace and automotive applications. The reduced weight of CFRP enhances fuel efficiency and structural performance compared to GFRP-based composites.

Strength and Stiffness Analysis

Carbon fiber reinforced polymer (CFRP) exhibits superior tensile strength and stiffness compared to glass fiber reinforced polymer (GFRP), making CFRP ideal for high-performance structural applications. The high modulus of elasticity in CFRP contributes to better load-bearing capacity and reduced deformation under stress, which enhances its durability in aerospace and automotive industries. Although GFRP offers cost advantages and adequate mechanical properties for less demanding applications, CFRP's exceptional strength-to-weight ratio ensures higher efficiency in strength and stiffness critical scenarios.

Cost and Economic Considerations

Carbon fiber reinforced polymer (CFRP) generally incurs higher material and manufacturing costs compared to glass fiber reinforced polymer (GFRP), driven by carbon fiber's superior strength-to-weight ratio and energy-intensive production. Despite the initial expense, CFRP offers long-term economic benefits in applications demanding high performance and durability, often reducing maintenance and lifecycle costs. GFRP remains a cost-effective choice for non-critical applications with lower mechanical property requirements, balancing affordability with reliable corrosion resistance.

Durability and Environmental Resistance

Carbon fiber reinforced polymer (CFRP) exhibits superior durability compared to glass fiber reinforced polymer (GFRP), with enhanced resistance to fatigue, impact, and moisture absorption. CFRP's environmental resistance is notable for its ability to withstand harsh chemical exposures and UV radiation without significant degradation. In contrast, GFRP tends to absorb more water and is more susceptible to environmental stress cracking and corrosion in aggressive environments.

Applications Across Industries

Carbon fiber reinforced polymer (CFRP) offers superior strength-to-weight ratio and stiffness, making it ideal for aerospace, automotive, and sports equipment applications where performance and weight reduction are critical. Glass fiber reinforced polymer (GFRP) dominates in construction, marine, and wind energy industries due to its cost-effectiveness, corrosion resistance, and ease of fabrication. Both composites find specialized uses, with CFRP preferred for highly stressed, lightweight components and GFRP suited for structural applications requiring durability and affordability.

Sustainability and Recycling Aspects

Carbon fiber reinforced polymer (CFRP) exhibits higher durability and strength-to-weight ratio compared to glass fiber reinforced polymer (GFRP), yet its recycling process remains complex and energy-intensive due to the thermoset matrix. GFRP offers more established recycling methods, including mechanical grinding and reuse in construction, making it relatively more sustainable in terms of circular economy practices. The lower embodied energy and ease of recycling position GFRP as a more eco-friendly alternative, while innovations in chemical recycling for CFRP aim to improve its sustainability footprint.

Future Trends in Composite Materials

Future trends in composite materials emphasize enhanced performance and sustainability, with Carbon Fiber Reinforced Polymer (CFRP) gaining traction for its superior strength-to-weight ratio and fatigue resistance compared to Glass Fiber Reinforced Polymer (GFRP). Innovations in recycling technologies and bio-based resins aim to reduce environmental impact, positioning CFRP as a more recyclable and eco-friendly option in aerospace and automotive industries. Ongoing research into hybrid composites combining CFRP and GFRP seeks to optimize cost-efficiency and mechanical properties for diverse engineering applications.

CFRP vs GFRP (Carbon fiber reinforced polymer vs Glass fiber reinforced polymer) Infographic

materialdif.com

materialdif.com