Chopped strand mat consists of randomly oriented glass fibers bound together by a binder, providing excellent conformability and uniform strength in multiple directions, making it ideal for complex shapes and curved surfaces. In contrast, woven roving features continuous fibers woven into a fabric, offering superior tensile strength and stiffness along the fiber directions, which enhances structural performance in load-bearing applications. Selecting between chopped strand mat and woven roving depends on the desired balance between surface finish, mechanical properties, and ease of molding for composite manufacturing.

Table of Comparison

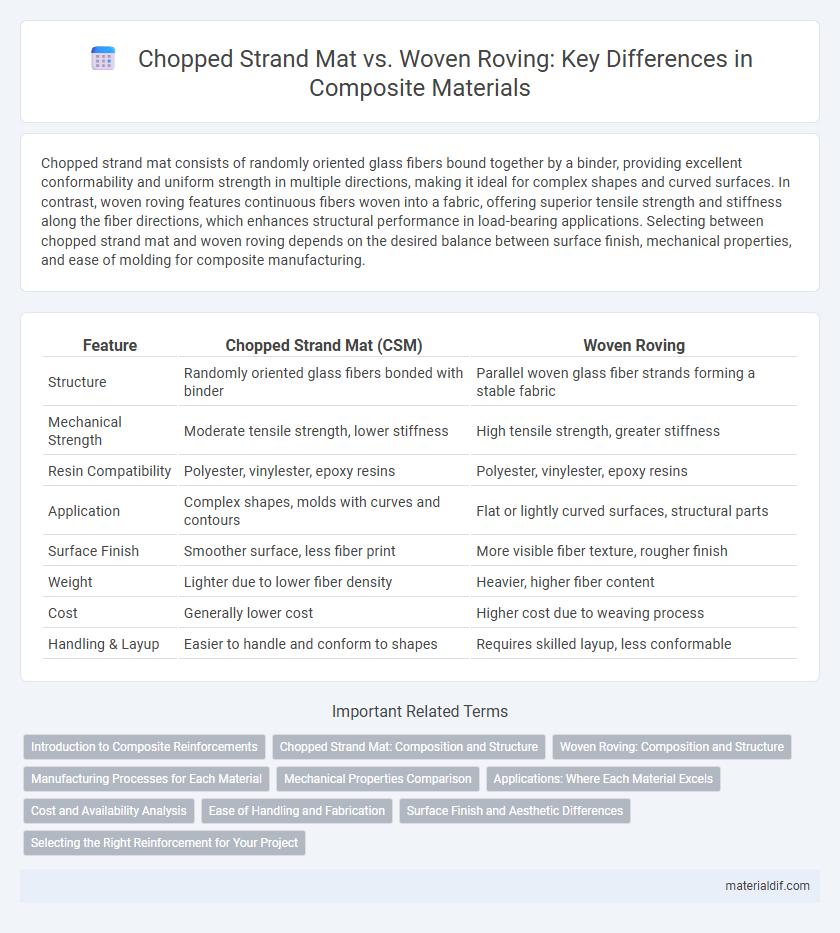

| Feature | Chopped Strand Mat (CSM) | Woven Roving |

|---|---|---|

| Structure | Randomly oriented glass fibers bonded with binder | Parallel woven glass fiber strands forming a stable fabric |

| Mechanical Strength | Moderate tensile strength, lower stiffness | High tensile strength, greater stiffness |

| Resin Compatibility | Polyester, vinylester, epoxy resins | Polyester, vinylester, epoxy resins |

| Application | Complex shapes, molds with curves and contours | Flat or lightly curved surfaces, structural parts |

| Surface Finish | Smoother surface, less fiber print | More visible fiber texture, rougher finish |

| Weight | Lighter due to lower fiber density | Heavier, higher fiber content |

| Cost | Generally lower cost | Higher cost due to weaving process |

| Handling & Layup | Easier to handle and conform to shapes | Requires skilled layup, less conformable |

Introduction to Composite Reinforcements

Chopped Strand Mat (CSM) consists of randomly oriented glass fibers held together by a binder, providing isotropic reinforcement that enhances impact resistance and surface finish in composite materials. Woven Roving (WR) features continuous fibers woven into a fabric, offering superior tensile strength and directional stiffness critical for load-bearing composite structures. Both reinforcements play essential roles in fiberglass composites, with CSM preferred for multidirectional strength and WR chosen for high-performance, structural applications.

Chopped Strand Mat: Composition and Structure

Chopped Strand Mat (CSM) is composed of randomly oriented glass fibers held together by a binder, creating a non-woven structure that provides excellent isotropic reinforcement. The random fiber distribution in CSM enhances resin wetting and allows for better molding in complex shapes compared to woven roving. The lightweight, fluffy texture of chopped strand mats offers superior conformity and impact resistance in composite applications.

Woven Roving: Composition and Structure

Woven roving consists of continuous fiberglass strands woven into a stable fabric, providing superior strength and dimensional stability compared to chopped strand mat. Its tightly interlaced fibers offer enhanced impact resistance and load-bearing capacity, making it ideal for structural composite applications. The uniform weave pattern ensures consistent resin impregnation and improved mechanical performance in finished parts.

Manufacturing Processes for Each Material

Chopped Strand Mat is produced by randomly layering glass fibers held together with a binder, creating a non-woven structure ideal for molding complex shapes and enabling faster resin saturation. Woven Roving is manufactured by interlacing continuous glass yarns perpendicular to each other, resulting in a fabric with higher tensile strength and dimensional stability suited for load-bearing applications. The distinct manufacturing techniques impact resin flow, mechanical performance, and ease of handling in composite fabrication.

Mechanical Properties Comparison

Chopped Strand Mat offers isotropic mechanical properties with moderate tensile strength and impact resistance, making it suitable for complex shapes and moldings. Woven Roving provides superior tensile strength, stiffness, and dimensional stability due to its woven fiber architecture, ideal for load-bearing applications. Mechanical performance varies significantly, with woven roving outperforming chopped strand mat in flexural modulus and tensile strength but offering less impact absorption.

Applications: Where Each Material Excels

Chopped strand mat excels in applications requiring complex shapes and molds due to its excellent conformability and isotropic strength distribution, making it ideal for boat hulls, automotive body parts, and tanks. Woven roving provides superior strength and stiffness along specific directions, which is essential for structural components such as wind turbine blades, pressure vessels, and aerospace parts. Selecting the appropriate reinforcement depends on the balance between formability and directional mechanical properties demanded by the composite application.

Cost and Availability Analysis

Chopped Strand Mat offers cost advantages due to lower manufacturing expenses and widespread availability as a staple in composite production. Woven Roving typically incurs higher costs because of its intricate weaving process but provides enhanced mechanical properties, which can justify its price in performance-critical applications. Availability for Chopped Strand Mat tends to be broader globally, while Woven Roving may have limited suppliers based on regional manufacturing capabilities.

Ease of Handling and Fabrication

Chopped Strand Mat offers superior ease of handling due to its random fiber orientation, allowing for easy draping over complex shapes without wrinkling or distortion. Woven Roving, with its unidirectional fiber bundles, provides higher structural integrity but is less flexible and requires more skill during fabrication to prevent fiber misalignment. The choice between the two hinges on balancing ease of handling for intricate molds versus the need for enhanced mechanical properties in the final composite.

Surface Finish and Aesthetic Differences

Chopped Strand Mat offers a rougher surface finish ideal for applications requiring enhanced mechanical bonding, while Woven Roving provides a smoother, more uniform surface suited for visible parts needing superior aesthetic appeal. The random orientation of fibers in Chopped Strand Mat results in a textured, matte look, contrasting with the distinct, patterned weave of Woven Roving that delivers a polished, glossy appearance. These surface finish differences are crucial when selecting materials for composites where both performance and visual quality are considered.

Selecting the Right Reinforcement for Your Project

Chopped Strand Mat (CSM) offers excellent conformability and is ideal for complex shapes, providing uniform strength in multiple directions, whereas Woven Roving delivers superior tensile strength and stiffness, making it suitable for load-bearing applications. Selecting the right reinforcement depends on your project's structural demands and surface finish requirements; CSM is preferred for lightweight, easy-to-mold parts, while Woven Roving is better for parts requiring high mechanical performance. Consider combining both materials in hybrid laminates to optimize strength, durability, and cost-effectiveness for your composite structure.

Chopped Strand Mat vs Woven Roving Infographic

materialdif.com

materialdif.com