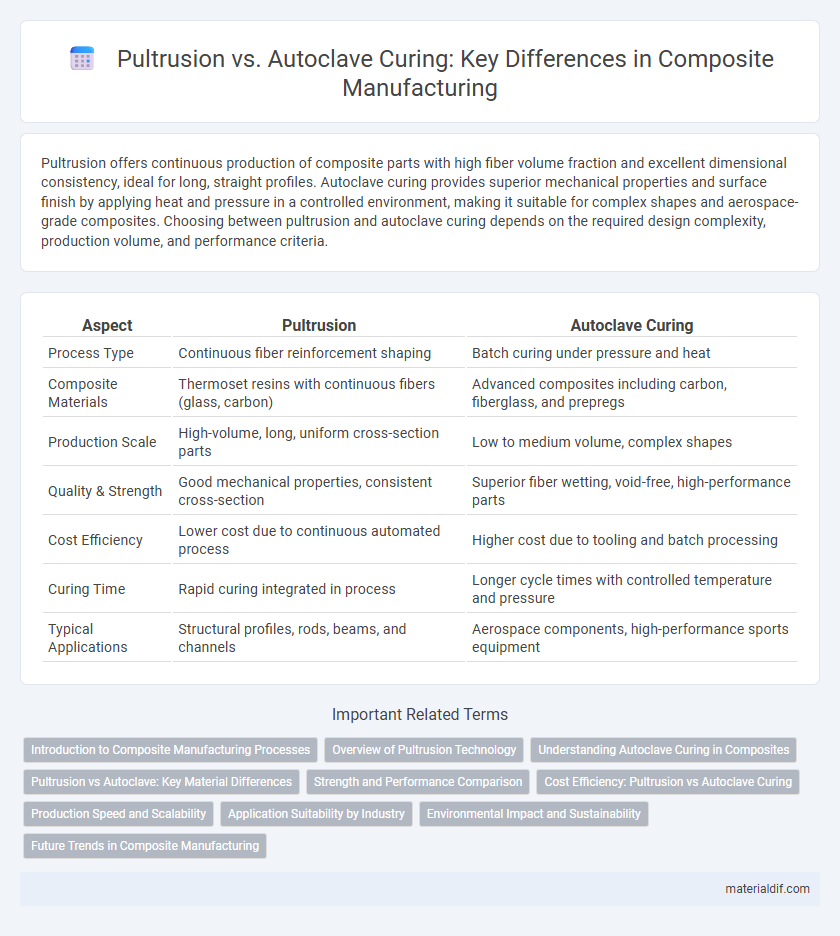

Pultrusion offers continuous production of composite parts with high fiber volume fraction and excellent dimensional consistency, ideal for long, straight profiles. Autoclave curing provides superior mechanical properties and surface finish by applying heat and pressure in a controlled environment, making it suitable for complex shapes and aerospace-grade composites. Choosing between pultrusion and autoclave curing depends on the required design complexity, production volume, and performance criteria.

Table of Comparison

| Aspect | Pultrusion | Autoclave Curing |

|---|---|---|

| Process Type | Continuous fiber reinforcement shaping | Batch curing under pressure and heat |

| Composite Materials | Thermoset resins with continuous fibers (glass, carbon) | Advanced composites including carbon, fiberglass, and prepregs |

| Production Scale | High-volume, long, uniform cross-section parts | Low to medium volume, complex shapes |

| Quality & Strength | Good mechanical properties, consistent cross-section | Superior fiber wetting, void-free, high-performance parts |

| Cost Efficiency | Lower cost due to continuous automated process | Higher cost due to tooling and batch processing |

| Curing Time | Rapid curing integrated in process | Longer cycle times with controlled temperature and pressure |

| Typical Applications | Structural profiles, rods, beams, and channels | Aerospace components, high-performance sports equipment |

Introduction to Composite Manufacturing Processes

Pultrusion and autoclave curing are essential processes in composite manufacturing, each offering unique advantages. Pultrusion is a continuous process ideal for producing constant cross-section profiles with high fiber alignment and resin impregnation. Autoclave curing uses high pressure and temperature to achieve superior mechanical properties and void reduction, making it suitable for complex, high-performance composite parts.

Overview of Pultrusion Technology

Pultrusion technology is a continuous manufacturing process used to create composite materials with a constant cross-section by pulling fibers through a resin bath and then into a heated die for curing. This method offers high production efficiency, excellent fiber alignment, and consistent mechanical properties, making it ideal for producing structural components like beams and rods. Compared to autoclave curing, pultrusion provides a cost-effective, automated alternative optimized for high-volume production of durable, lightweight composites.

Understanding Autoclave Curing in Composites

Autoclave curing in composites involves applying heat and pressure within a sealed chamber to enhance the material's mechanical properties by minimizing voids and consolidating layers. This process achieves superior fiber-matrix bonding and improved surface finish compared to pultrusion, which primarily relies on continuous pulling without controlled pressure. Autoclave curing is essential for high-performance aerospace components where precision and strength are critical.

Pultrusion vs Autoclave: Key Material Differences

Pultrusion produces continuous composite profiles by pulling fibers through a resin bath and heated die, resulting in consistent cross-sections and excellent fiber alignment, while autoclave curing involves applying heat and pressure to pre-formed layups, enhancing resin consolidation and reducing void content. Pultruded composites often exhibit high fiber volume fractions and superior longitudinal strength but may have limitations in complex shapes compared to autoclave-cured parts, which provide superior surface finish and mechanical properties in intricate geometries. Material differences also include resin chemistry adaptability, with pultrusion favoring thermoset resins optimized for fast cure cycles, whereas autoclave curing accommodates a wider range of high-performance thermosetting and thermoplastic matrices.

Strength and Performance Comparison

Pultrusion offers consistent fiber alignment and high tensile strength due to continuous processing, making it ideal for long, uniform composite parts. Autoclave curing enables superior void reduction and improved resin consolidation, resulting in enhanced interlaminar strength and overall mechanical performance. Comparing both methods, autoclave-cured composites typically exhibit higher strength-to-weight ratios and better fatigue resistance, while pultruded composites excel in cost-efficiency and dimensional stability for structural applications.

Cost Efficiency: Pultrusion vs Autoclave Curing

Pultrusion offers significantly lower production costs due to its continuous manufacturing process and reduced labor requirements compared to the batch-oriented autoclave curing method. Autoclave curing involves high energy consumption and expensive equipment, leading to increased operational expenses, especially for large or complex composite parts. Pultrusion's cost efficiency is further enhanced by faster cycle times and minimal material waste, making it ideal for high-volume production of composite profiles.

Production Speed and Scalability

Pultrusion offers high production speed by enabling continuous manufacturing of composite profiles with consistent cross-sections, making it ideal for large-scale, repetitive production runs. Autoclave curing, while providing superior mechanical properties and quality, involves batch processing with longer cure cycles, limiting throughput and scalability. For projects requiring rapid output and scalable volume, pultrusion presents a more efficient solution compared to the time-intensive, labor-intensive autoclave curing process.

Application Suitability by Industry

Pultrusion is ideal for manufacturing continuous, high-strength composite profiles used extensively in construction, electrical, and transportation industries due to its cost-efficiency and consistency. Autoclave curing offers superior performance and quality control for aerospace, automotive, and sports equipment sectors where complex geometries and high mechanical properties are critical. The selection between pultrusion and autoclave curing depends on factors such as production volume, part complexity, and required material performance in the targeted industry.

Environmental Impact and Sustainability

Pultrusion offers a more energy-efficient manufacturing process compared to autoclave curing, significantly reducing carbon emissions due to its continuous production and lower temperature requirements. Autoclave curing demands substantial energy input from high-pressure and high-temperature cycles, contributing to a larger environmental footprint. The sustainability advantage of pultrusion is enhanced by its minimal volatile organic compound (VOC) emissions and reduced waste generation, making it a greener option for composite fabrication.

Future Trends in Composite Manufacturing

Future trends in composite manufacturing emphasize automation and sustainability, with pultrusion gaining traction for high-volume, cost-effective production of continuous fiber composites. Autoclave curing remains essential for high-performance aerospace components due to its superior consolidation and mechanical properties but faces challenges from high energy consumption. Innovations such as out-of-autoclave (OOA) processes and advanced resin systems aim to bridge quality and efficiency gaps, driving hybrid curing strategies that combine pultrusion speed with autoclave-level performance.

Pultrusion vs Autoclave Curing Infographic

materialdif.com

materialdif.com