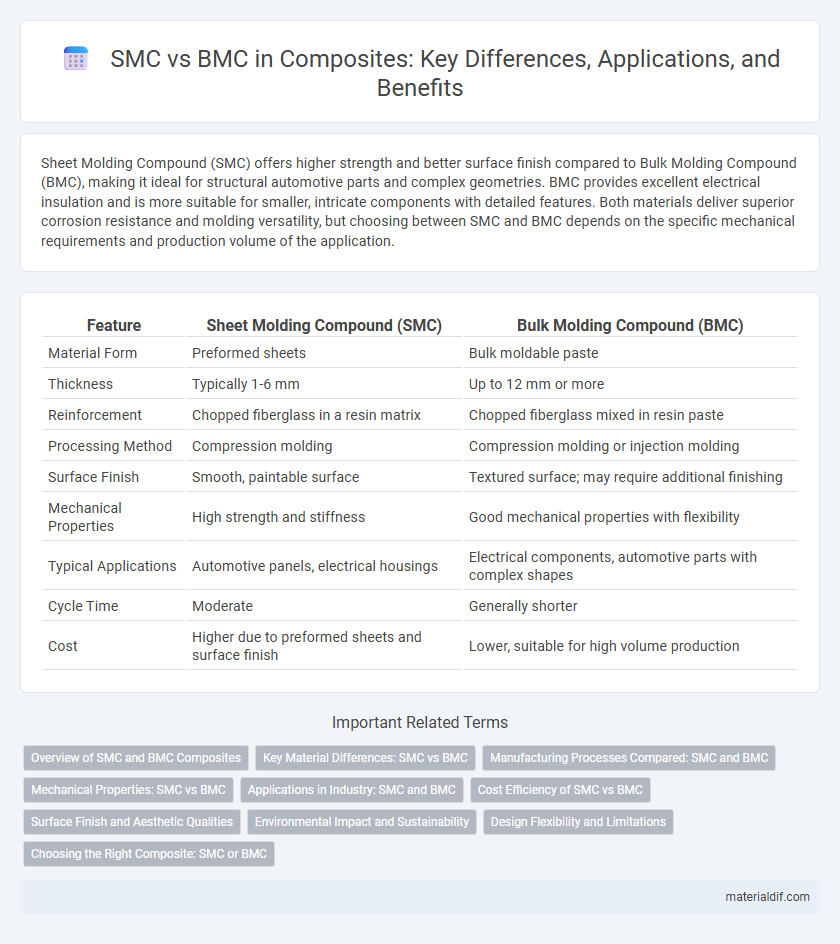

Sheet Molding Compound (SMC) offers higher strength and better surface finish compared to Bulk Molding Compound (BMC), making it ideal for structural automotive parts and complex geometries. BMC provides excellent electrical insulation and is more suitable for smaller, intricate components with detailed features. Both materials deliver superior corrosion resistance and molding versatility, but choosing between SMC and BMC depends on the specific mechanical requirements and production volume of the application.

Table of Comparison

| Feature | Sheet Molding Compound (SMC) | Bulk Molding Compound (BMC) |

|---|---|---|

| Material Form | Preformed sheets | Bulk moldable paste |

| Thickness | Typically 1-6 mm | Up to 12 mm or more |

| Reinforcement | Chopped fiberglass in a resin matrix | Chopped fiberglass mixed in resin paste |

| Processing Method | Compression molding | Compression molding or injection molding |

| Surface Finish | Smooth, paintable surface | Textured surface; may require additional finishing |

| Mechanical Properties | High strength and stiffness | Good mechanical properties with flexibility |

| Typical Applications | Automotive panels, electrical housings | Electrical components, automotive parts with complex shapes |

| Cycle Time | Moderate | Generally shorter |

| Cost | Higher due to preformed sheets and surface finish | Lower, suitable for high volume production |

Overview of SMC and BMC Composites

Sheet Molding Compound (SMC) composites are fiber-reinforced materials combining fiberglass, resin, and fillers in a moldable sheet form, offering excellent strength-to-weight ratio and high-quality surface finish for complex geometries. Bulk Molding Compound (BMC) composites consist of short fiber materials mixed thoroughly with resin in a putty-like consistency, ideal for intricate, high-volume injection molding processes requiring uniform mechanical properties. Both SMC and BMC provide enhanced thermal resistance, corrosion resistance, and dimensional stability, making them essential in automotive, electrical, and industrial applications.

Key Material Differences: SMC vs BMC

Sheet Molding Compound (SMC) and Bulk Molding Compound (BMC) differ significantly in their key materials; SMC involves a fiber-reinforced thermoset resin with longer glass fibers (approximately 1/8 inch) uniformly distributed within a polyester or vinyl ester resin matrix, providing superior strength and surface finish. BMC contains shorter glass fibers (typically 1/4 inch or less) mixed with a thermoset resin, commonly polyester or epoxy, resulting in a more moldable material suited for complex shapes but with lower mechanical strength. The fiber length and resin viscosity distinctions between SMC and BMC directly impact their processing methods, structural performance, and application suitability in composite manufacturing.

Manufacturing Processes Compared: SMC and BMC

Sheet Molding Compound (SMC) involves a continuous glass fiber reinforcement combined with a polyester resin, compression molded under heat and pressure, allowing for complex shapes and higher strength-to-weight ratios. Bulk Molding Compound (BMC) consists of shorter chopped fibers mixed uniformly in a resin paste, molded through injection or compression processes, offering faster cycle times but generally lower structural performance. SMC's process offers better fiber orientation control for enhanced mechanical properties, whereas BMC excels in producing intricate parts with smaller dimensions and higher production speeds.

Mechanical Properties: SMC vs BMC

Sheet Molding Compound (SMC) typically exhibits superior mechanical properties compared to Bulk Molding Compound (BMC), including higher tensile strength and better impact resistance due to its longer fiber reinforcement and improved fiber orientation. SMC's enhanced stiffness and dimensional stability make it ideal for structural applications requiring durability and load-bearing capacity. In contrast, BMC's shorter fiber length results in lower mechanical performance, making it more suitable for complex-shaped parts where high strength is less critical.

Applications in Industry: SMC and BMC

Sheet Molding Compound (SMC) and Bulk Molding Compound (BMC) are extensively used in automotive, electrical, and aerospace industries due to their high strength-to-weight ratio and corrosion resistance. SMC's ability to be molded into complex shapes makes it ideal for large automotive body panels and structural components, while BMC's fine fillers and high electrical insulation properties suit it for smaller, intricate parts in electrical housings and connectors. Both materials enhance manufacturing efficiency and durability in high-performance industrial applications.

Cost Efficiency of SMC vs BMC

Sheet Molding Compound (SMC) offers higher cost efficiency compared to Bulk Molding Compound (BMC) due to its lower material waste and faster cycle times in high-volume production. SMC's ability to produce larger, more complex parts with consistent quality reduces post-processing expenses and labor costs. While BMC is suitable for intricate, smaller components, SMC's scalable manufacturing process provides greater overall savings in automotive and industrial composite applications.

Surface Finish and Aesthetic Qualities

Sheet Molding Compound (SMC) offers superior surface finish and aesthetic qualities compared to Bulk Molding Compound (BMC) due to its smoother texture and reduced porosity. SMC's finer fillers and optimized resin formulation result in consistent color and gloss levels, enhancing visual appeal for automotive and consumer applications. BMC typically exhibits a rougher surface with visible fibers or air pockets, making it less suitable for high-quality exterior finishes.

Environmental Impact and Sustainability

Sheet Molding Compound (SMC) offers a lower environmental impact than Bulk Molding Compound (BMC) due to its higher fiber content and reduced resin use, leading to less volatile organic compound (VOC) emissions during manufacturing. SMC components typically exhibit superior recyclability and energy efficiency throughout their lifecycle, supporting sustainability goals in automotive and construction industries. In contrast, BMC's higher resin proportion results in greater carbon footprint and limited end-of-life recyclability, posing challenges for environmental compliance.

Design Flexibility and Limitations

Sheet Molding Compound (SMC) offers greater design flexibility compared to Bulk Molding Compound (BMC) due to its ability to accommodate more complex shapes and thicker parts with continuous fiber reinforcement. SMC enables the production of larger components with improved mechanical properties, while BMC is typically suited for smaller, more intricate parts with shorter fibers, limiting its structural strength and dimensional stability. Mold complexity and tooling costs are generally higher for SMC, but this tradeoff allows for enhanced performance in automotive and aerospace composite applications.

Choosing the Right Composite: SMC or BMC

Sheet Molding Compound (SMC) offers superior mechanical strength and surface finish, making it ideal for automotive and structural applications requiring complex shapes and high durability. Bulk Molding Compound (BMC) provides excellent electrical insulation and is well-suited for smaller, intricate components with tight tolerances in the electrical and appliance industries. Selecting between SMC and BMC depends on the specific performance requirements, such as structural integrity, surface quality, and manufacturing complexity.

SMC vs BMC Infographic

materialdif.com

materialdif.com