Vacuum bagging offers a cost-effective method for composite curing by applying uniform pressure and removing air voids, enhancing laminate quality without requiring expensive equipment. Autoclave curing, however, provides higher pressure and temperature control, resulting in superior fiber consolidation and mechanical properties for advanced composite parts. Choosing between vacuum bagging and autoclave curing depends on the desired performance, production scale, and budget constraints.

Table of Comparison

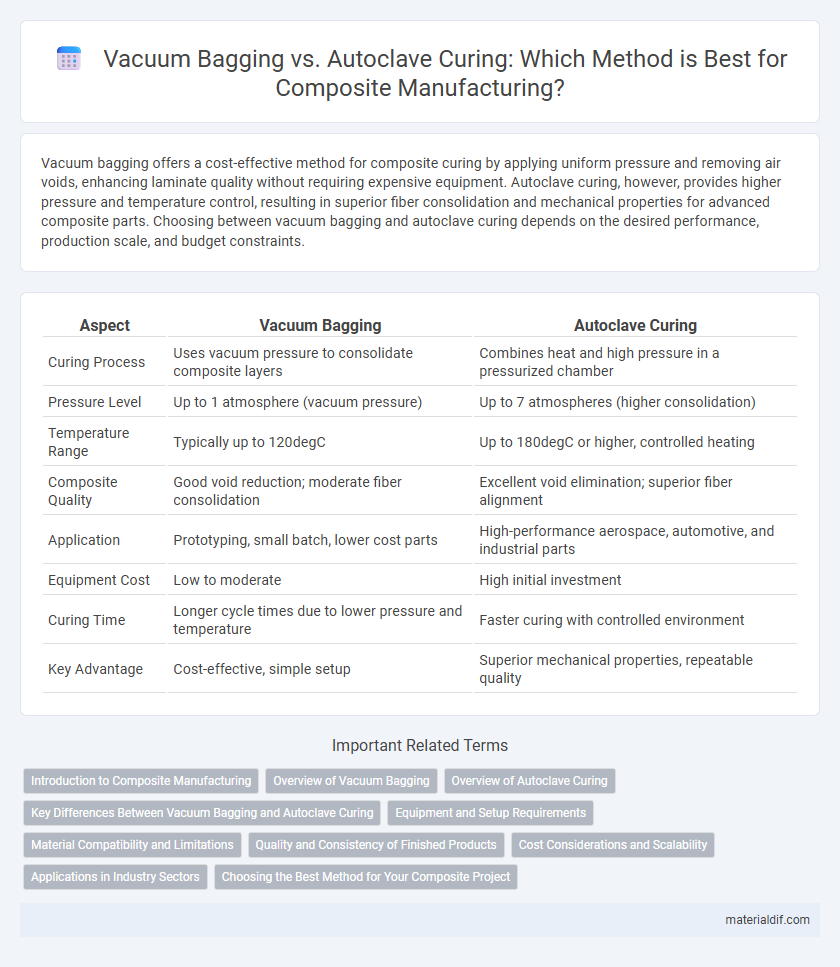

| Aspect | Vacuum Bagging | Autoclave Curing |

|---|---|---|

| Curing Process | Uses vacuum pressure to consolidate composite layers | Combines heat and high pressure in a pressurized chamber |

| Pressure Level | Up to 1 atmosphere (vacuum pressure) | Up to 7 atmospheres (higher consolidation) |

| Temperature Range | Typically up to 120degC | Up to 180degC or higher, controlled heating |

| Composite Quality | Good void reduction; moderate fiber consolidation | Excellent void elimination; superior fiber alignment |

| Application | Prototyping, small batch, lower cost parts | High-performance aerospace, automotive, and industrial parts |

| Equipment Cost | Low to moderate | High initial investment |

| Curing Time | Longer cycle times due to lower pressure and temperature | Faster curing with controlled environment |

| Key Advantage | Cost-effective, simple setup | Superior mechanical properties, repeatable quality |

Introduction to Composite Manufacturing

Vacuum bagging and autoclave curing are essential processes in composite manufacturing that enhance material quality and structural performance. Vacuum bagging removes air and excess resin by applying vacuum pressure, enabling better fiber-resin ratio and reducing voids in composite laminates. Autoclave curing applies heat and high pressure simultaneously, improving resin flow, consolidation, and mechanical properties for aerospace-grade composites.

Overview of Vacuum Bagging

Vacuum bagging is a composite manufacturing process that uses a vacuum to remove air and compress layers of fiber and resin, ensuring improved consolidation and reduced void content. This technique enhances laminate quality by evenly distributing pressure over the part during curing without the need for expensive autoclave equipment. Vacuum bagging is widely used for producing high-performance composites in aerospace and automotive industries due to its cost-effectiveness and ability to maintain structural integrity.

Overview of Autoclave Curing

Autoclave curing involves applying heat and pressure within a sealed, high-pressure vessel to composite materials, resulting in superior laminate consolidation and void reduction. This method enables precise control over temperature, pressure, and cure cycle, enhancing fiber-matrix adhesion and mechanical properties. Typically used in aerospace and high-performance industries, autoclave curing achieves higher quality composites compared to vacuum bagging alone.

Key Differences Between Vacuum Bagging and Autoclave Curing

Vacuum bagging utilizes a sealed plastic film to apply uniform pressure via vacuum, effectively removing air and excess resin from composite layups, resulting in improved consolidation and reduced void content. Autoclave curing combines elevated temperature and high pressure within a pressurized chamber, producing superior mechanical properties and enhanced fiber-to-resin ratio through precise control of curing conditions. Key differences include the pressure levels, with autoclave curing reaching up to 100 psi or more compared to vacuum bagging's sub-atmospheric pressure, and the resulting composite quality, as autoclave curing typically delivers higher structural performance suitable for aerospace-grade components.

Equipment and Setup Requirements

Vacuum bagging requires minimal equipment, including vacuum pumps, release films, and vacuum bags, making it a cost-effective option for composite curing with simpler setup and portability. Autoclave curing demands specialized high-pressure vessels, precise temperature and pressure control systems, and significant infrastructure, leading to higher capital investment and more complex setup procedures. The choice between vacuum bagging and autoclave curing heavily depends on production scale, desired composite performance, and available manufacturing resources.

Material Compatibility and Limitations

Vacuum bagging suits a wide range of composite materials including carbon fiber, fiberglass, and aramid, offering flexibility with lower temperature and pressure thresholds, typically up to 85 psi and 120degC. Autoclave curing demands composite prepregs compatible with high pressure (up to 100 psi or more) and elevated temperatures reaching 180degC or higher, enabling superior fiber consolidation and void reduction. Limitations of vacuum bagging include less effective void removal and lower mechanical performance in high-demand applications, while autoclave curing is constrained by high equipment costs and the necessity for resin systems tailored to elevated curing cycles.

Quality and Consistency of Finished Products

Vacuum bagging offers improved resin consolidation and reduced void content, resulting in high-quality composite laminates with consistent fiber volume fraction. Autoclave curing enhances strength and surface finish by applying elevated pressure and temperature, yielding superior mechanical properties and uniformity across large production runs. Both methods significantly reduce porosity, but autoclave curing provides greater control over fiber alignment and resin flow, ensuring exceptional repeatability in aerospace-grade composite components.

Cost Considerations and Scalability

Vacuum bagging offers a cost-effective solution for small to medium composite production runs due to lower initial equipment investment and simpler setup. Autoclave curing requires significant capital expenditure for high-pressure ovens but enables consistent, high-quality output ideal for large-scale manufacturing and aerospace-grade composites. Scalability favors autoclave processes for volume production, while vacuum bagging remains competitive for prototypes and limited batches.

Applications in Industry Sectors

Vacuum bagging dominates aerospace and automotive industries for prototyping and small-scale composite parts due to its cost-effectiveness and ease of use in curing carbon fiber and fiberglass components. Autoclave curing, favored in aerospace, defense, and high-performance sports sectors, delivers superior mechanical properties and surface finish by applying high pressure and temperature, essential for critical load-bearing structures. The choice between methods hinges on production volume, part complexity, and quality requirements, with autoclaves preferred for high-precision, large batch manufacturing and vacuum bagging suited for custom or low-volume runs.

Choosing the Best Method for Your Composite Project

Vacuum bagging offers cost-effective, low-pressure consolidation ideal for small to medium-sized composite parts, enabling improved fiber-to-resin ratios and reduced void content. Autoclave curing applies high pressure and temperature to achieve superior mechanical properties, surface finish, and dimensional accuracy, making it the preferred choice for high-performance aerospace and automotive applications. Selecting the best method depends on project scale, budget, dimensional tolerances, and performance requirements, with vacuum bagging suited for prototyping and autoclaving favored for critical, high-strength components.

Vacuum Bagging vs Autoclave Curing Infographic

materialdif.com

materialdif.com