Mat reinforcement in composite PET provides enhanced isotropic strength and superior impact resistance by distributing loads evenly across the material, making it ideal for applications requiring multidirectional durability. Woven reinforcement, with its interlaced fiber structure, offers higher tensile strength and stiffness along specific directions, suitable for components that experience unidirectional or predictable stresses. Selecting between mat and woven reinforcement depends on the performance requirements, with mat favoring balanced toughness and woven prioritizing directional strength.

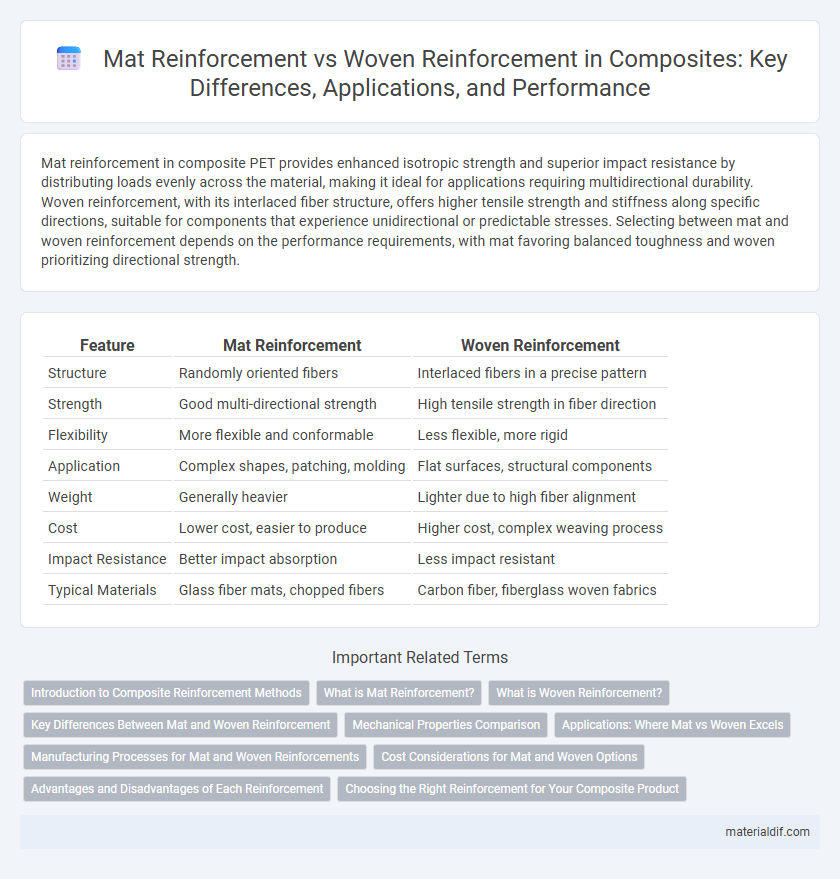

Table of Comparison

| Feature | Mat Reinforcement | Woven Reinforcement |

|---|---|---|

| Structure | Randomly oriented fibers | Interlaced fibers in a precise pattern |

| Strength | Good multi-directional strength | High tensile strength in fiber direction |

| Flexibility | More flexible and conformable | Less flexible, more rigid |

| Application | Complex shapes, patching, molding | Flat surfaces, structural components |

| Weight | Generally heavier | Lighter due to high fiber alignment |

| Cost | Lower cost, easier to produce | Higher cost, complex weaving process |

| Impact Resistance | Better impact absorption | Less impact resistant |

| Typical Materials | Glass fiber mats, chopped fibers | Carbon fiber, fiberglass woven fabrics |

Introduction to Composite Reinforcement Methods

Mat reinforcement involves randomly oriented fibers bonded in a mat form, providing isotropic strength and enhanced impact resistance in composite structures. Woven reinforcement features interlaced fibers arranged in a systematic pattern, offering superior directional strength and stiffness critical for load-bearing applications. Selecting between mat and woven reinforcement depends on specific mechanical performance requirements, manufacturing processes, and cost considerations in composite fabrication.

What is Mat Reinforcement?

Mat reinforcement consists of randomly oriented chopped fibers bonded into a unified structure, providing isotropic strength and improved impact resistance in composite materials. Unlike woven reinforcement, mat reinforcement offers enhanced conformity to complex shapes and better resin permeability, resulting in stronger adhesion and reduced void content. This type of reinforcement is commonly used in applications requiring uniform strength distribution and superior surface finish, such as automotive panels and marine hulls.

What is Woven Reinforcement?

Woven reinforcement is a type of composite material reinforcement made by interlacing fibers in a crisscross pattern, typically using materials such as fiberglass, carbon fiber, or aramid fibers. This structure provides enhanced strength and stiffness in multiple directions, making it ideal for applications requiring balanced mechanical properties. Woven reinforcements improve impact resistance and dimensional stability compared to unidirectional or mat reinforcements.

Key Differences Between Mat and Woven Reinforcement

Mat reinforcement consists of randomly oriented chopped fibers that provide isotropic strength, while woven reinforcement features interlaced continuous fibers offering higher tensile strength and directional load-bearing capacity. Mat reinforcements are typically easier to mold into complex shapes due to their flexibility, whereas woven reinforcements deliver superior mechanical performance and dimensional stability. The choice between mat and woven reinforcement depends on specific application requirements, including strength, stiffness, and manufacturing complexity in composite structures.

Mechanical Properties Comparison

Mat reinforcement exhibits higher impact resistance and better crack propagation control compared to woven reinforcement, making it suitable for applications requiring energy absorption. Woven reinforcement offers superior tensile strength and stiffness due to its organized fiber architecture, enhancing load-bearing capacity and dimensional stability. The choice between mat and woven reinforcement significantly influences the composite's mechanical performance, particularly in strength, durability, and resistance to deformation.

Applications: Where Mat vs Woven Excels

Mat reinforcement excels in applications requiring complex shapes and irregular geometries, such as automotive body panels and aerospace interior components, due to its excellent conformability and easy draping. Woven reinforcement is preferred in high-performance structural applications like marine hulls and sporting goods, where superior tensile strength and fatigue resistance are critical. Industries targeting weight reduction with high stiffness-to-weight ratios benefit most from the directional strength characteristics of woven reinforcements.

Manufacturing Processes for Mat and Woven Reinforcements

Mat reinforcement manufacturing involves randomly oriented fiber layers bonded through thermal, chemical, or mechanical means, enabling ease of molding complex shapes and uniform resin distribution. Woven reinforcement production consists of interlacing yarns in precise warp and weft patterns, providing higher tensile strength and dimensional stability due to consistent fiber alignment. Both manufacturing processes impact composite mechanical properties and processing efficiency, influencing final product performance in automotive, aerospace, and construction applications.

Cost Considerations for Mat and Woven Options

Mat reinforcement generally offers a lower initial cost compared to woven reinforcement due to simpler manufacturing processes and reduced material usage. Woven reinforcement, while often more expensive upfront, provides enhanced mechanical properties and durability that can reduce long-term maintenance and replacement costs. Evaluating the total cost of ownership, including installation, performance lifespan, and potential repair expenses, is crucial for selecting between mat and woven composite reinforcements.

Advantages and Disadvantages of Each Reinforcement

Mat reinforcement offers excellent isotropic strength and ease of molding complex shapes due to randomly oriented fibers, making it ideal for large, curved composite structures; however, it generally provides lower tensile strength and stiffness compared to woven reinforcement. Woven reinforcement delivers superior mechanical properties along specific fiber directions, enhancing load-bearing capacity and impact resistance, but it can be more challenging to conform to intricate shapes and may result in higher production costs. Choosing between mat and woven reinforcements depends on balancing structural requirements, manufacturing complexity, and cost efficiency within the composite application.

Choosing the Right Reinforcement for Your Composite Product

Mat reinforcement offers random fiber orientation that enhances isotropic strength and impact resistance, making it ideal for complex shapes and high-stress applications. Woven reinforcement provides superior directional strength and stiffness due to its interlaced fiber structure, which benefits load-bearing components requiring precise mechanical performance. Selecting the right reinforcement depends on balancing mechanical demands, cost-effectiveness, and manufacturing processes to optimize composite product performance.

Mat Reinforcement vs Woven Reinforcement Infographic

materialdif.com

materialdif.com