SMC (Sheet Molding Compound) offers superior surface finish and dimensional stability compared to BMC (Bulk Molding Compound), making it ideal for large, complex parts with tight tolerances. BMC provides faster curing times and excellent fill properties for smaller, intricate components, making it cost-effective for high-volume production. Both materials feature reinforced thermoset resins but differ in processing methods and applications, influencing material selection based on performance and manufacturing requirements.

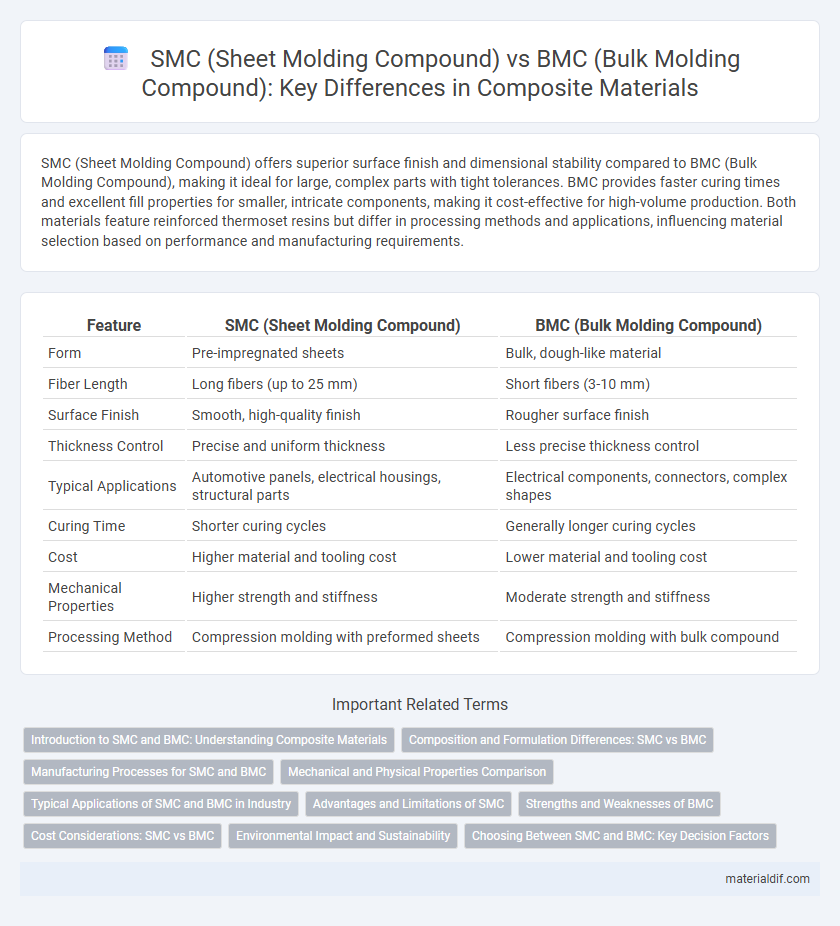

Table of Comparison

| Feature | SMC (Sheet Molding Compound) | BMC (Bulk Molding Compound) |

|---|---|---|

| Form | Pre-impregnated sheets | Bulk, dough-like material |

| Fiber Length | Long fibers (up to 25 mm) | Short fibers (3-10 mm) |

| Surface Finish | Smooth, high-quality finish | Rougher surface finish |

| Thickness Control | Precise and uniform thickness | Less precise thickness control |

| Typical Applications | Automotive panels, electrical housings, structural parts | Electrical components, connectors, complex shapes |

| Curing Time | Shorter curing cycles | Generally longer curing cycles |

| Cost | Higher material and tooling cost | Lower material and tooling cost |

| Mechanical Properties | Higher strength and stiffness | Moderate strength and stiffness |

| Processing Method | Compression molding with preformed sheets | Compression molding with bulk compound |

Introduction to SMC and BMC: Understanding Composite Materials

Sheet Molding Compound (SMC) is a fiber-reinforced composite material combining glass fibers, resins, and fillers in a sheet form, providing excellent strength-to-weight ratio and surface finish. Bulk Molding Compound (BMC) consists of a mixture of resin, chopped glass fibers, and fillers in a dough-like consistency, optimized for complex shapes and high-volume production. Both SMC and BMC are thermoset composites widely used in automotive, electrical, and construction industries for their durability, dimensional stability, and corrosion resistance.

Composition and Formulation Differences: SMC vs BMC

SMC (Sheet Molding Compound) consists of a blend of thermosetting resins, typically polyester or vinyl ester, reinforced with continuous glass fibers and fillers, resulting in a malleable sheet form for moldability. BMC (Bulk Molding Compound) features a similar resin system but combines short glass fibers uniformly dispersed within a bulk, dough-like paste, offering superior flow and precise molding for smaller, intricate parts. The key formulation difference lies in SMC's fiber orientation and sheet structure promoting high strength and surface finish, whereas BMC's bulk form enhances versatility in complex geometries with balanced mechanical properties.

Manufacturing Processes for SMC and BMC

Sheet Molding Compound (SMC) manufacturing involves layering resin-impregnated fiber sheets, which are then compressed under heat and pressure in a mold to cure, resulting in consistent thickness and smooth surface finishes. Bulk Molding Compound (BMC) is produced by mixing chopped fibers, fillers, and resin into a fine paste that is then injected or compression molded, allowing for more complex shapes but with slightly lower surface quality. Both processes utilize thermosetting resin matrices, with SMC favored for large, flat panels and BMC for intricate, high-volume parts requiring detailed features.

Mechanical and Physical Properties Comparison

SMC (Sheet Molding Compound) offers superior mechanical properties such as higher tensile strength and enhanced impact resistance compared to BMC (Bulk Molding Compound), making it suitable for structural applications. BMC provides better flow characteristics and is ideal for complex, intricate shapes due to its superior moldability and uniformity. Both materials exhibit good electrical insulation and corrosion resistance, but SMC generally achieves higher stiffness and surface finish quality, while BMC excels in processing speed and cost efficiency.

Typical Applications of SMC and BMC in Industry

SMC (Sheet Molding Compound) is widely used in automotive body panels, electrical housings, and industrial equipment due to its excellent surface finish and high strength-to-weight ratio. BMC (Bulk Molding Compound) finds typical applications in electrical components, consumer appliances, and smaller compression-molded parts because of its superior flow characteristics and dimensional stability. Both materials serve critical roles in industries requiring lightweight, corrosion-resistant, and electrically insulating composites.

Advantages and Limitations of SMC

SMC (Sheet Molding Compound) offers superior surface finish and dimensional stability compared to BMC (Bulk Molding Compound), making it ideal for high-precision automotive and aerospace components. SMC's enhanced fiber alignment results in improved mechanical strength and impact resistance, while its compression molding process allows for larger and more complex shapes. However, SMC typically has higher material and processing costs than BMC and may require longer curing cycles, limiting its use in high-volume, cost-sensitive applications.

Strengths and Weaknesses of BMC

BMC (Bulk Molding Compound) offers excellent electrical insulation properties and superior dimensional stability, making it ideal for complex molded parts in automotive and electrical applications. Its main weaknesses include lower mechanical strength and longer curing times compared to SMC, limiting its use in high-stress structural components. BMC is preferred for smaller, intricate shapes where precision and surface finish are critical, but it is less suitable for large, load-bearing parts.

Cost Considerations: SMC vs BMC

SMC (Sheet Molding Compound) generally incurs higher tooling and material costs compared to BMC (Bulk Molding Compound) due to its sheet form and longer curing times, impacting overall production expenses. BMC offers cost advantages with lower initial tooling investments and faster cycle times, making it suitable for high-volume manufacturing. Evaluating specific application requirements and volume projections is essential to determine the most cost-effective composite molding compound between SMC and BMC.

Environmental Impact and Sustainability

SMC (Sheet Molding Compound) generates less waste during production compared to BMC (Bulk Molding Compound), enhancing material efficiency and reducing landfill contributions. SMC typically involves lower emissions and energy consumption in the molding process, delivering a smaller carbon footprint relative to BMC. The recyclability of SMC scrap further supports circular economy efforts, promoting sustainable manufacturing practices in composite applications.

Choosing Between SMC and BMC: Key Decision Factors

Choosing between Sheet Molding Compound (SMC) and Bulk Molding Compound (BMC) depends on factors such as part size, complexity, and surface finish requirements. SMC is ideal for larger, thicker parts with superior surface aesthetics and structural strength, while BMC suits smaller, intricately shaped components demanding high dimensional accuracy and electrical insulation. Cost considerations and production volume also influence the decision, with SMC generally preferred for high-volume automotive or industrial applications.

SMC (Sheet Molding Compound) vs BMC (Bulk Molding Compound) Infographic

materialdif.com

materialdif.com